Self-heat preservation heat insulation wall

A self-insulation and wall technology, applied in the direction of walls, building components, buildings, etc., to achieve the effects of simple construction operation, high material utilization rate and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

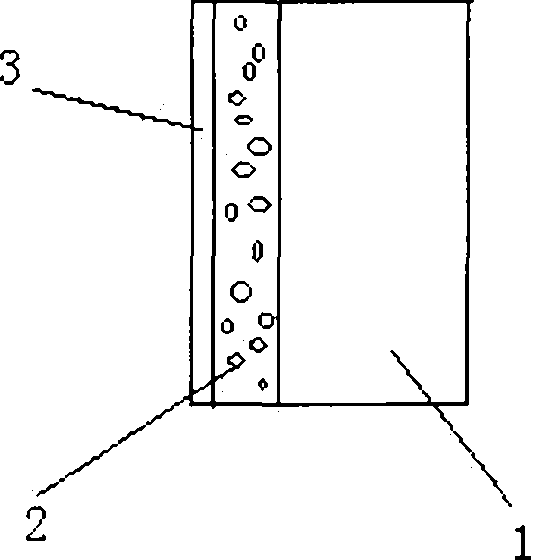

[0017] Embodiment 1: A self-insulating wall, comprising a retaining wall 1, a plaster layer 2 and a finish layer 3, the retaining wall 1 is composed of concrete beams and columns and light-weight thermal insulation brick masonry, and the retaining wall 1 is The masonry mortar used and the plastering mortar used in the stucco layer 2 are both a kind of inorganic thermal insulation mortar for lightweight thermal insulation brick masonry. The raw material components and weight content are as follows: 10 parts of fly ash, vitrified 15 parts of microbeads, 8 parts of bentonite, 2 parts of slaked lime powder, 400 parts of sand, and 100 parts of cement.

Embodiment 2

[0018] Embodiment 2: A self-insulating wall, comprising a retaining wall 1, a stucco layer 2 and a finish layer 3, the retaining wall 1 is composed of concrete beams and columns and light-weight thermal insulation brick masonry, and the retaining wall 1 is The masonry mortar used and the plastering mortar used in the stucco layer 2 are both a kind of inorganic thermal insulation mortar for lightweight thermal insulation brick masonry. The raw material components and weight content are as follows: 30 parts of fly ash, vitrified 35 parts of microbeads, 2 parts of bentonite, 10 parts of slaked lime powder, 250 parts of sand, and 100 parts of cement.

Embodiment 3

[0019] Embodiment 3: A self-insulating wall, comprising a retaining wall 1, a plaster layer 2 and a finishing layer 3, the retaining wall 1 is composed of concrete beams and columns and light-weight thermal insulation brick masonry, and the retaining wall 1 is The masonry mortar used and the plastering mortar used in the stucco layer 2 are both a kind of inorganic thermal insulation mortar for lightweight thermal insulation brick masonry, and its raw material components and weight contents are as follows: 20 parts of fly ash, vitrified 25 parts of microbeads, 4 parts of bentonite, 5 parts of hydrated lime powder, 300 parts of sand, and 100 parts of cement.

[0020] In the method for preparing inorganic thermal insulation mortar for light-weight thermal insulation brick masonry in the above three embodiments, first, the fly ash, sand, bentonite, slaked lime powder and cement are mixed uniformly by machinery, then the vitrified microbeads are added, and the Mechanically mix even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com