Automatic test system of sound surface filtering device

An automatic test system and filter device technology, applied in the field of test systems, to achieve the effect of improving reliability, avoiding accidental errors, and convenient and quick detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

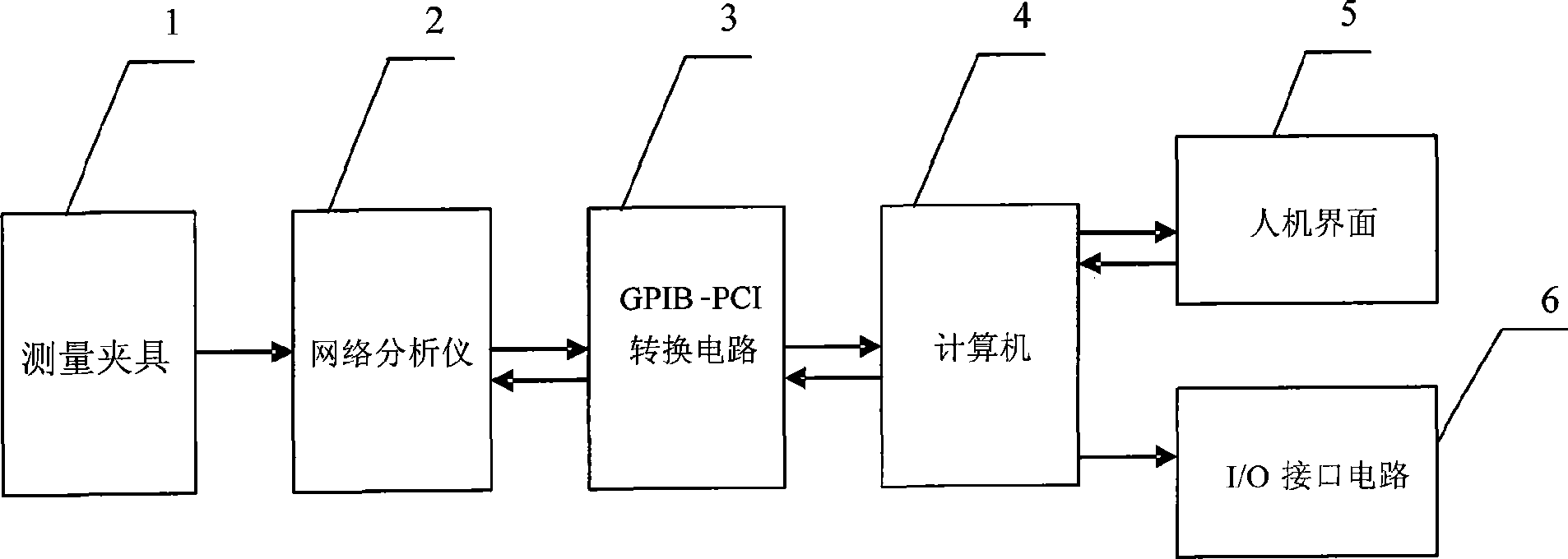

[0020] figure 1 It is a block diagram of the present invention. Such as figure 1 As shown, the present invention includes:

[0021] Measuring fixture 1, used to clamp the device under test;

[0022] The network analyzer 2 connected to the measurement fixture 1 is composed of three major connections: a frequency sweep signal source, a detector and a receiver. Under the control of the microprocessor installed inside the detector, the reflection characteristics or transmission The characteristics are scanned, the test parameters are collected, and the result of the scan (the test parameters collected) is output through the GPIB interface of the network analyzer 2;

[0023] The present invention also includes:

[0024] GPIB-PCI conversion circuit 3 is connected with the GPIB interface of network analyzer 2, and the GPIB bus output is conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com