Weld joint real time monitoring method of electric welding machine

A technology of real-time monitoring and electric welding machine, applied in real-time monitoring of welding seam position, real-time monitoring of welding seam of electric welding machine, can solve problems such as unstable system operation and abnormal operation, achieve real-time sampling and high-speed transmission, and good real-time performance , the effect of high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

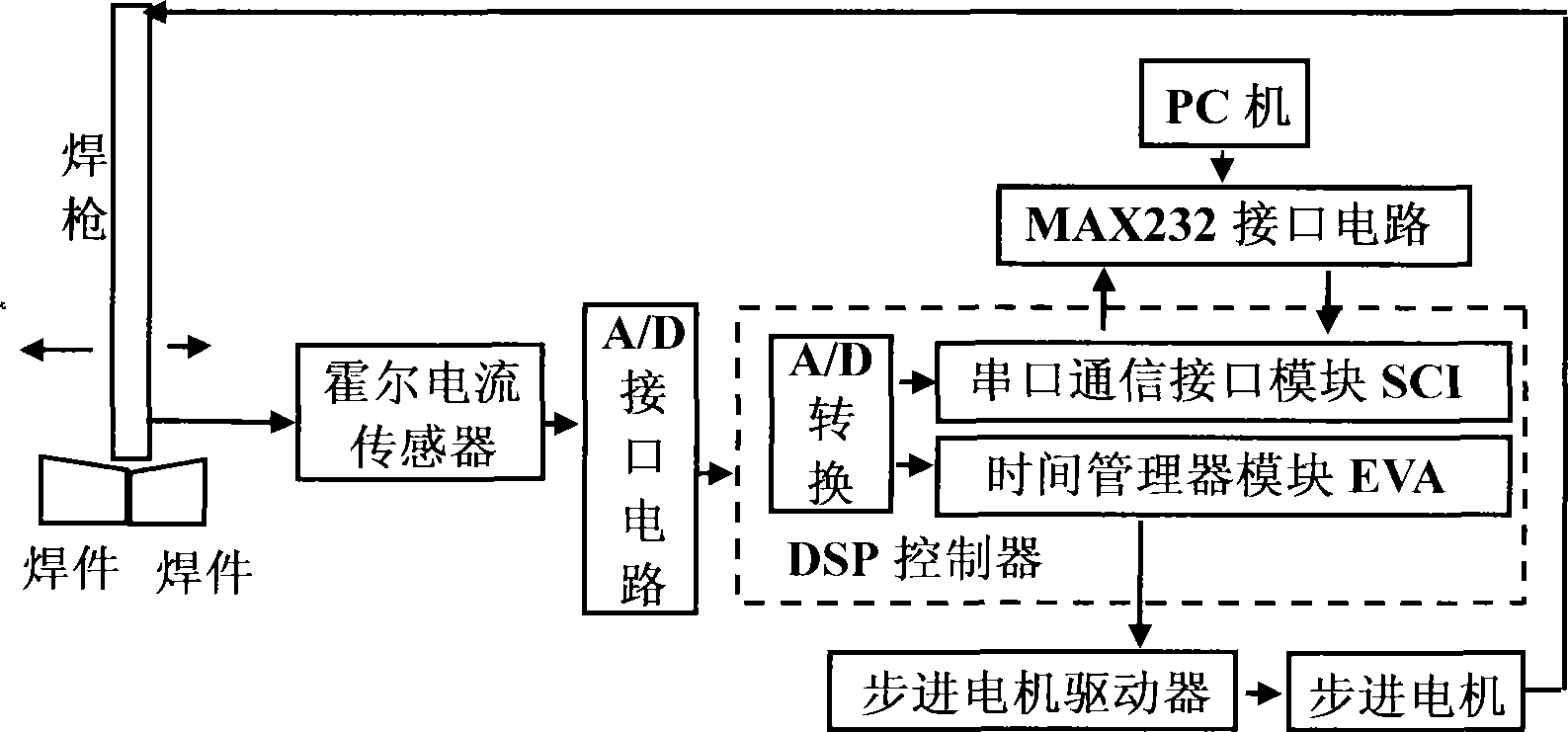

[0013] The method for real-time monitoring of the welding seam of the electric welding machine of the present invention will be further described in detail below.

[0014] The welding seam real-time monitoring method of the electric welding machine of the present invention comprises the steps of:

[0015] 1) Convert the welding current into a corresponding voltage signal through the Hall current sensor;

[0016] 2) After the signal is filtered, the DSP controller collects it and completes the A / D conversion of the analog signal, and then divides it into two outputs: one signal is output through the operation of the algorithm programmed in the event manager module to obtain an output control signal to control The actuator performs deviation correction, and the other channel is sent to the PC through the serial communication module of the DSP;

[0017] 3) The PC is used as the upper computer to perform various processing, storage and graphical display of the welding current on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com