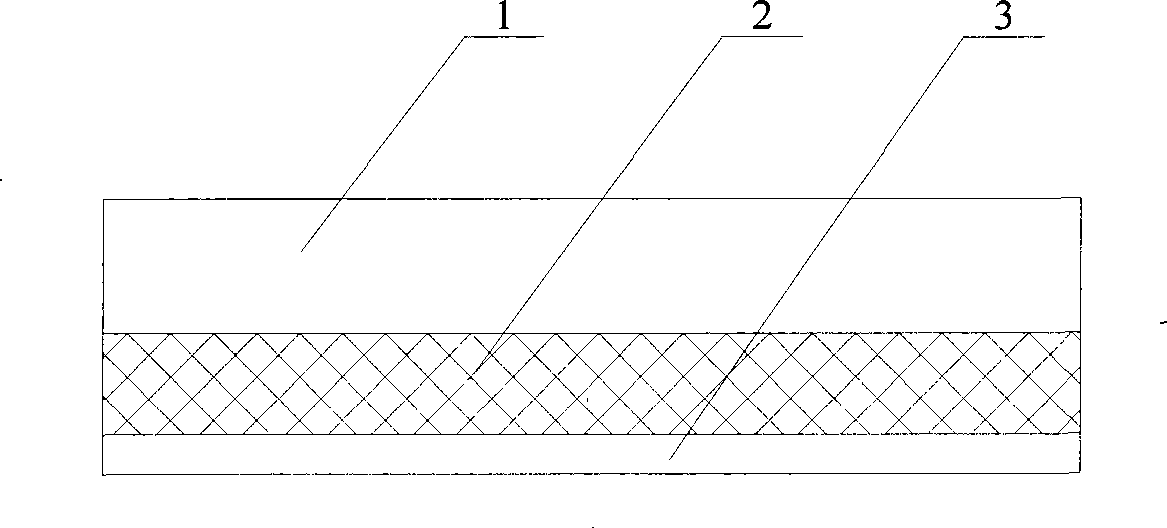

Heat binding flocking film and preparation method thereof

A production method and thermal lamination technology, applied in chemical instruments and methods, synthetic resin layered products, decorative arts, etc., can solve the problems of high scrap rate, falling off, easy edge removal, etc., and achieve short processing cycle and simple process , The effect of low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

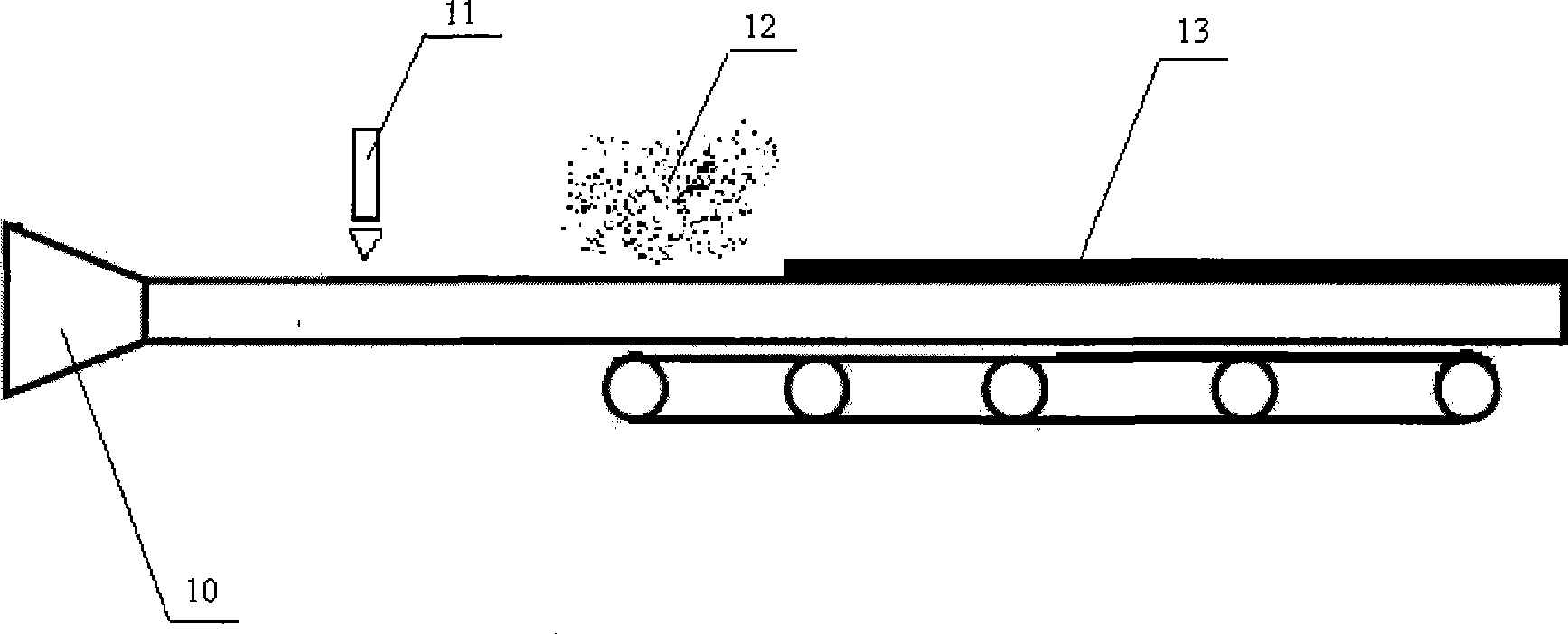

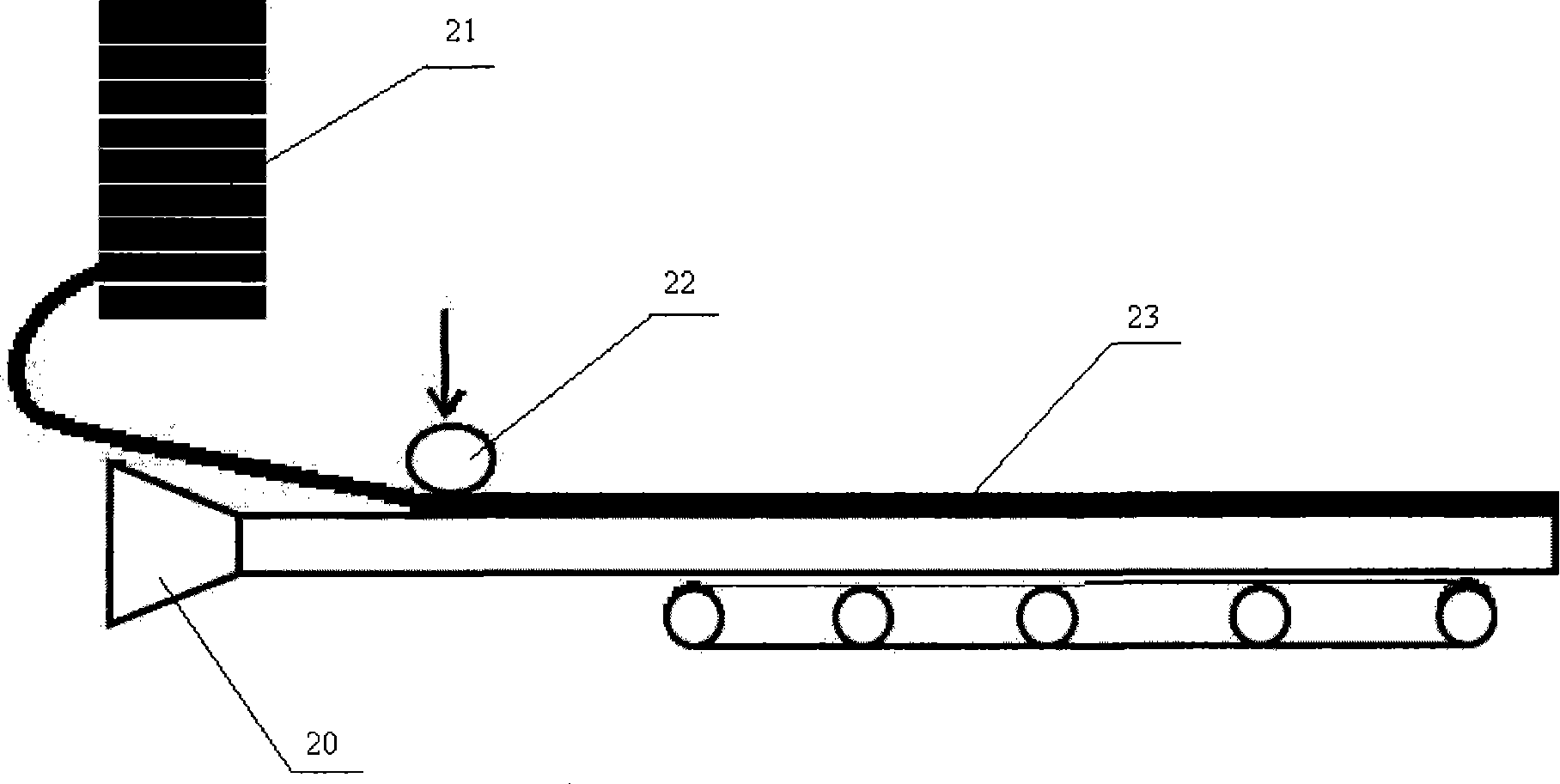

[0034] The film base layer is made of 0.3mm thick polyvinyl chloride (PVC) material, the fluff is made of 3D (0.8mm) polyester material, and the flocking glue is made of two-component oily polyurethane flocking glue. The upper surface of the film base layer is cleaned and rolled. The winding is smooth, and the electrostatic flocking machine produced by Shandong Xinfeng Flocking Equipment Co., Ltd. is used for electrostatic flocking.

[0035] Put the film to be flocked on the input roller of the electrostatic flocking machine, connect it with the traction film, pass through the drying tunnel, and fix it around the temporary paper tube; adjust the position of the scraper so that it is 0.25-0.3 away from the upper surface of the base film mm, mix the two-component oily polyurethane flocking glue evenly and pour it into the glue tank in front of the scraper, turn on the motor of the electrostatic flocking machine, turn on the temperature of the drying tunnel, and the film base begi...

Embodiment 2

[0038] The base layer of the film is made of 0.1mm thick thermoplastic elastomer (TPE), the fluff is made of 1.5D (0.5mm) acrylic fiber, the flocking glue is two-component water-based polyurethane flocking glue, and the electrostatic flocking equipment is the same as in Example 1.

[0039] Clean the surface of the film and wind it evenly. Put the film base layer to be flocked on the input stick of the electrostatic flocking machine, connect it with the traction film, pass through the drying tunnel, and fix it on the temporary paper tube; adjust the position of the scraper, Make it 0.22-0.28mm away from the upper surface of the base film, mix the two-component oily polyurethane flocking glue evenly and pour it into the glue tank in front of the scraper, turn on the motor of the electrostatic flocking machine, turn on the temperature of the drying tunnel, and the film base begins to slowly Go forward and confirm that the base layer of the film is flat and wrinkle-free; apply glue...

Embodiment 3

[0042]The difference between this embodiment and Embodiment 1 is that the film base is made of 0.2mm thick thermoplastic vulcanizate (TPV) material, the fluff is made of 3D (0.5mm) acrylic fiber material, and the flocking glue is two-component water-based polyurethane flocking glue. The distance between the scraper and the upper surface of the base layer film is 0.25-0.30mm, the speed of fluffing is 100g / min, the flocking voltage of the electrostatic flocking machine is 48KV-62KV, and the temperature of the drying tunnel is 110°C-120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com