Encapsulating material composition of LED

A technology of light-emitting diodes and packaging materials, which is applied in the direction of electrical components, circuits, and other chemical processes. It can solve the problems of low refractive index, low light-emitting efficiency of LEDs, and inapplicability, so as to improve the refractive index and solve the problem of insufficient thermal stress dissipation. highly acceptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Formula Table:

[0037]

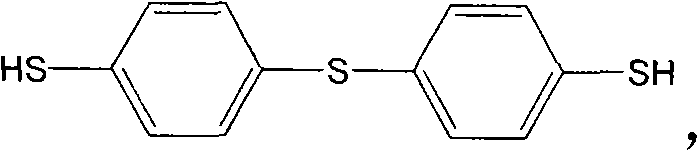

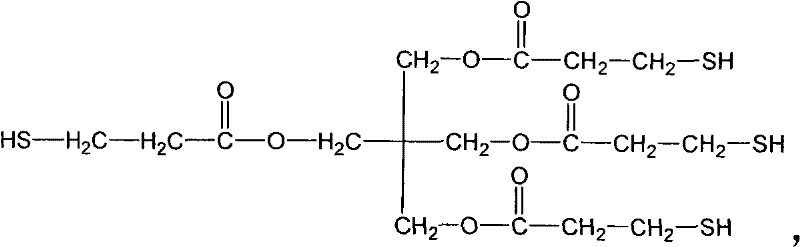

[0038]Wherein the bifunctional epoxy resin is Diglycidyl ether of Bisphenol A (Diglycidyl ether of Bisphenol A) (EPON-828, purchased from Shell chemical. company), and the aromatic ring-containing bifunctional mercaptan hardener is 4, 4'-dimercapto diphenyl sulfide (4,4'-Thiobisbenzonethiol) (abbreviated as TBT, purchased from TCI Co. company), the aliphatic four-functional mercaptan hardener is tetrakis (3-mercaptopropionic acid) pentapentetate Alcohol (pentaerythritol tetrakis (3-mercaptopropionate)) (PTT-3MP, purchased from TCI Co. company), the catalyst is Quaternary phosphonium bromide (U-cat 5003, purchased from San-apro limited. company) , antioxidants are hindered phenolic antioxidants (Chinox1076, available from Sigma-Aldrich Co.) and organic phosphite antioxidants (Tris (nonylphenyl) phosphate, 1178, available from Sigma-Aldrich Co.).

[0039] Put the epoxy resin (EPON-828), hardener (TBT) and catalyst (U-cat 5003) [0.2wt% (EPON-8...

Embodiment 2

[0043] Formula Table:

[0044]

[0045] The difference between embodiment 2 and embodiment 1 is that the difunctional epoxy resin wherein is propanediol F diglycidyl ether (Diglycidyl ether of Bisphenol F) (EPON-830, purchased from DIC company), in embodiment 2 It does not contain antioxidants, and the ratio of TBT and PTT-3MP is changed, the ratio of TBT is increased, and the ratio of PTT-3MP is decreased.

[0046] Put the epoxy resin (EPON-830), hardener (TBT+ PTT-3MP) and catalyst (U-cat 5003) in the formula table into the reactor, stir and mix at 60°C for 75 minutes, then put the uniformly mixed The resin material was defoamed in vacuum for 20 minutes, and then the above material was poured into a mold, heated in an oven at 80°C for 1 hour, and then heated at 160°C for 2 hours to complete the hardening.

[0047] The packaging material sample prepared in Example 2 was measured in the same manner as in Example 1, and the obtained results are listed in Table 1.

Embodiment 3

[0049] Formula Table:

[0050]

[0051]

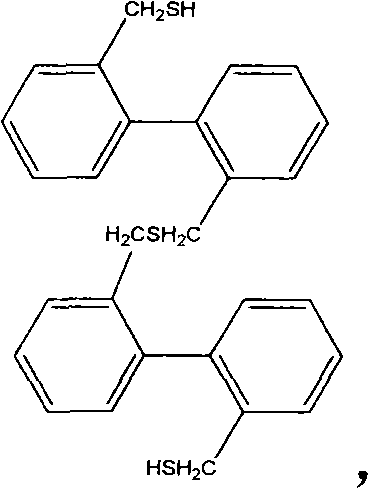

[0052] The difference between Example 3 and Example 2 is that the dithiol hardener containing aromatic ring structure is bis-[2,2'-bis(mercaptomethyl)-1,1-bisphenylmethane sulfide] (Bi- [2,2'-bis(mercaptomethyl)-1,1-biphenylmethlene sulfide]) (Biphenyl dithiol for short), synthesized by the inventor).

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com