Twisting, pressing and rolling washing mode of washing machine and full automatic washing machine thereof

A fully automatic washing machine and washing method technology, applied in the field of washing machines, can solve the problems of easy wear and tear, noise of easily damaged transmission gears, complex clutch mechanism, etc., and achieve the effects of low noise, saving detergent, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

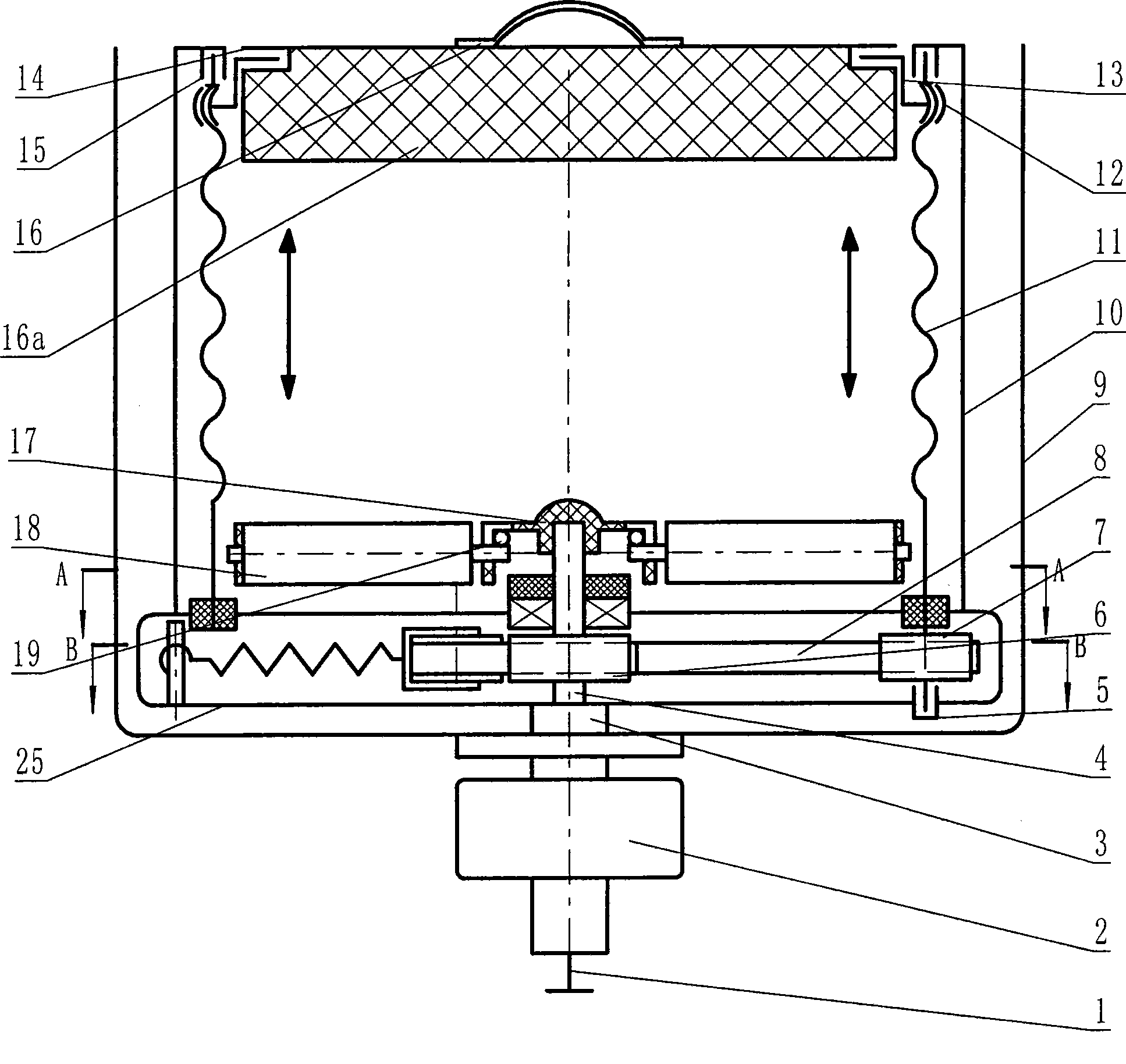

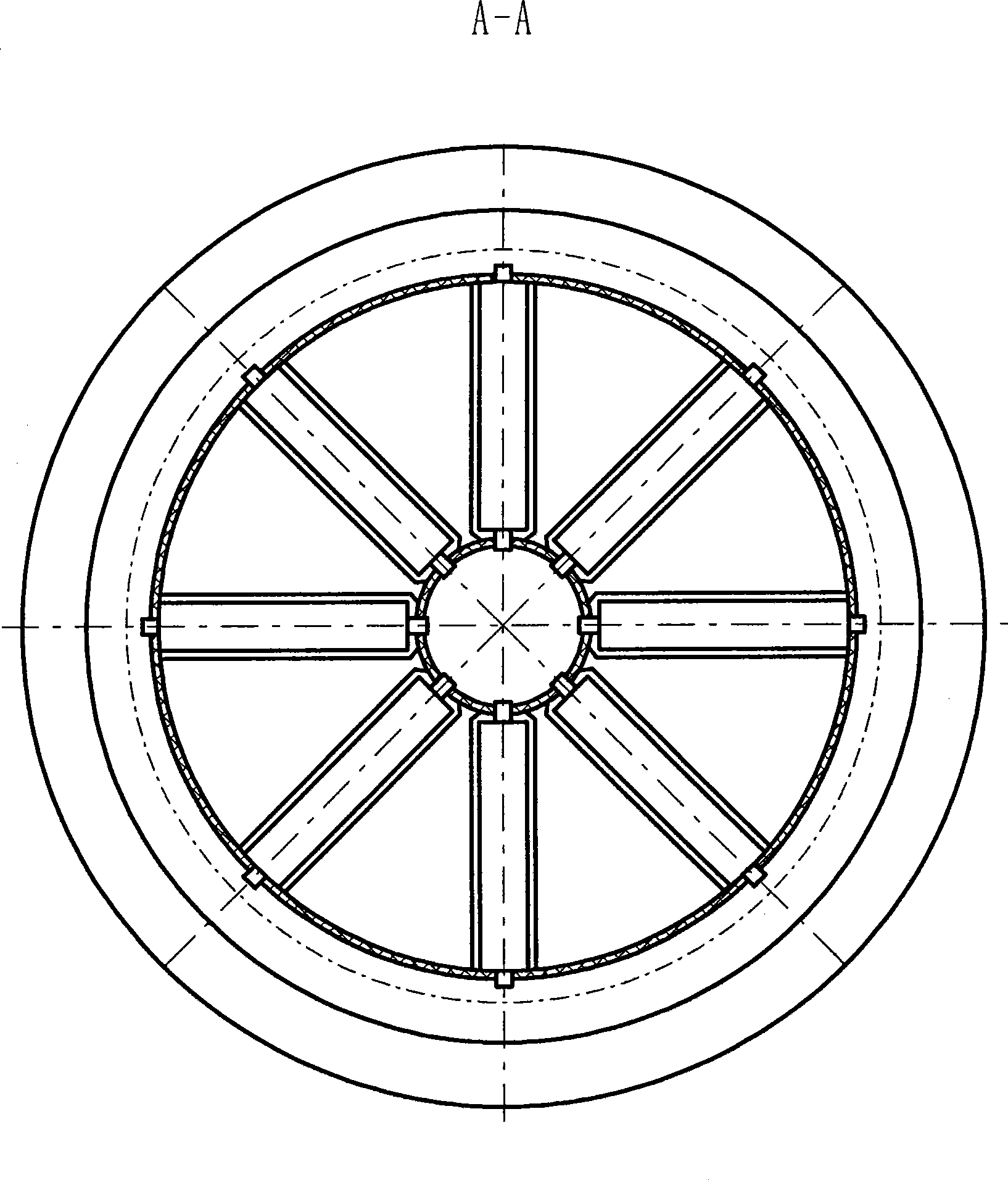

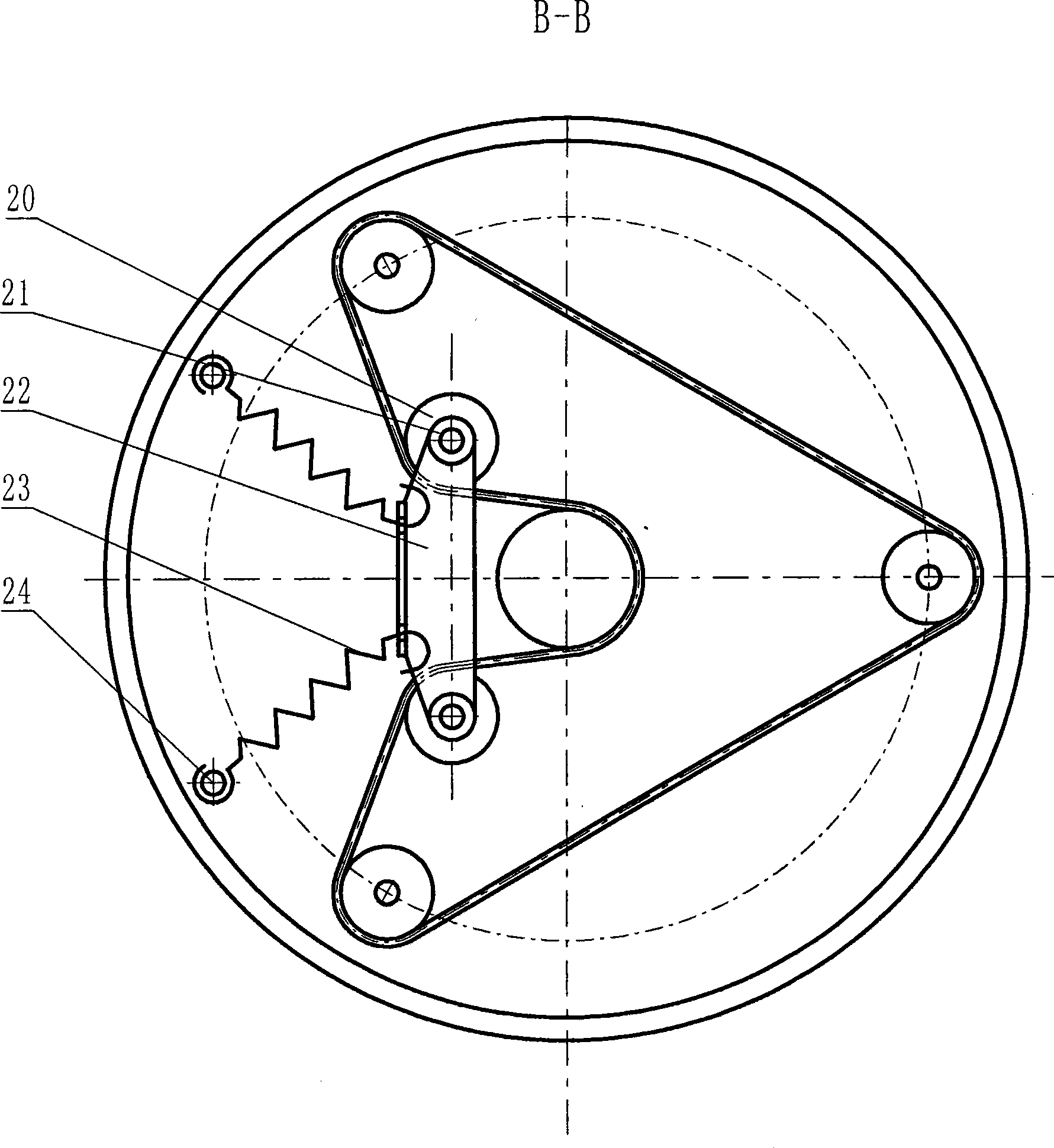

[0023] figure 1 , figure 2 , image 3 It is a front view and a top view cross-sectional schematic view of the structure of the embodiment of the automatic washing machine of the present invention, which is mainly composed of an axial pressure plate device, a radial rolling device and a belt transmission device.

[0024] 1. The axial pressure plate device includes: 3 lead screws 11 placed on the inner circumference of the inner barrel 10, upper and lower supports 15 and 5 of the lead screw placed on the upper and lower ends of the lead screw, and the lead screw is connected with the ring pressure through its nut 12. Plate 13 is connected, and the pressure plate is built-in with center cover 16 and high-quality foamed plastics (elastomer 16a). The central cover 16 and the foamed plastics can be opened and closed on demand through the coupling ring 14 to put in the clothes.

[0025] The quantity of the above-mentioned leading screws 11 can be 2 or more. Elastic body 16a can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com