Insulation device of sliding bearing for vertical motor

A technology of sliding bearings and insulating devices, which is applied in the direction of electromechanical devices, electric components, casings/covers/supports, etc., can solve the problems of insulation performance degradation, growth, failure, etc., and achieve extended service life and high single-production output , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

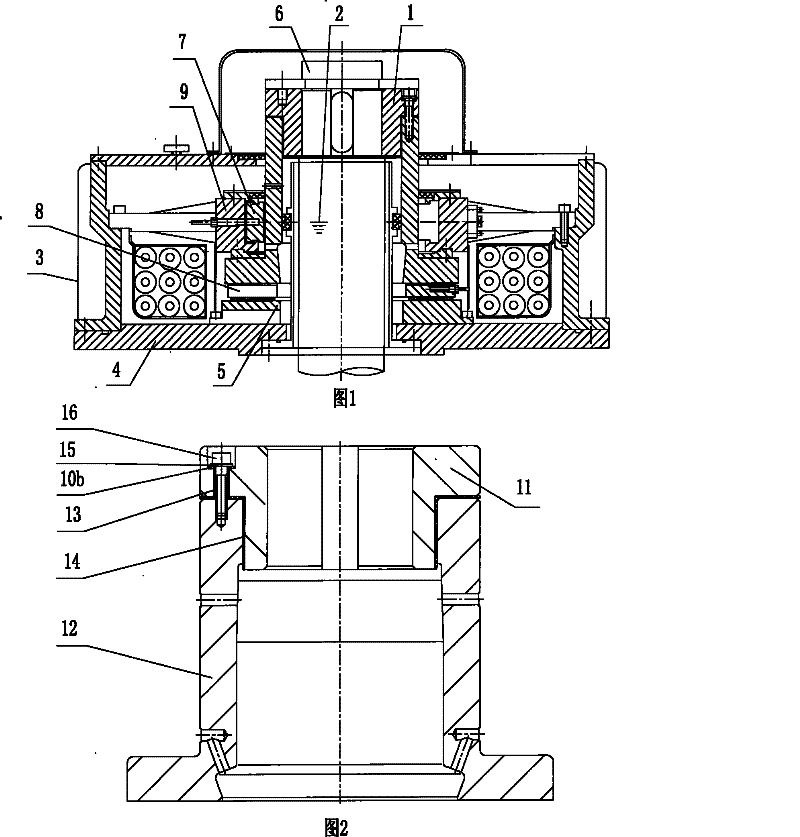

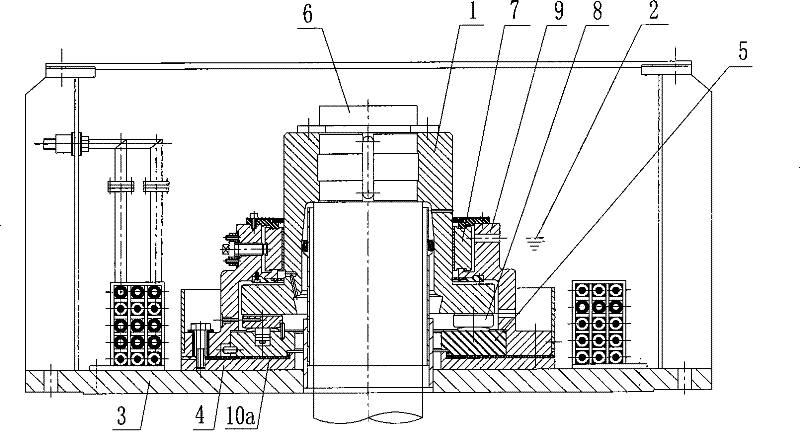

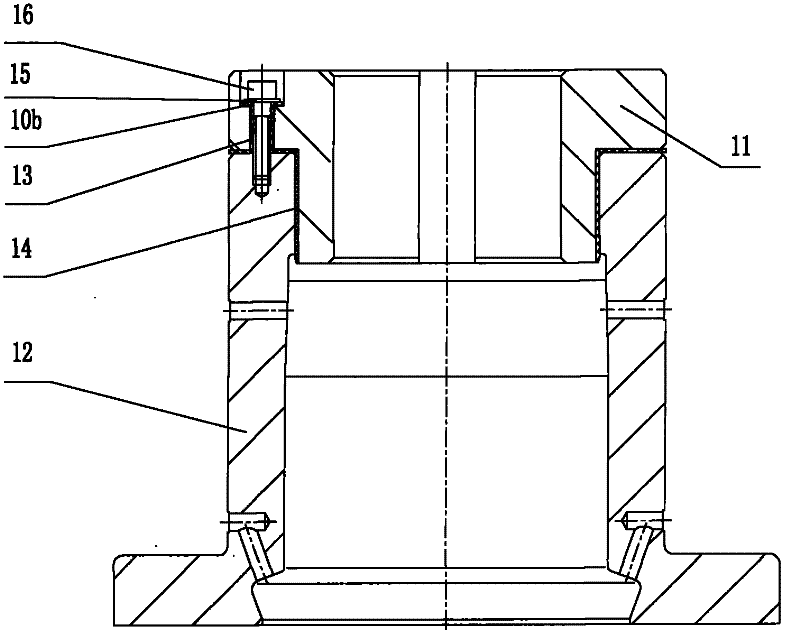

[0020] Referring to the accompanying drawings, an insulation device for sliding bearings for vertical motors, which includes a box body 3 passing through the motor shaft 6 and vertically installed on the motor housing, and a thrust head 1 and a guide bush 7 adapted to the motor shaft 6 1. The thrust tile 8 is fixed on the support plate 4 at the bottom of the box body 3 by the tile guide seat 9 through the connecting plate 5 and the insulating backing plate 10a. The thrust head 1 is formed by combining the shaft sleeve 11 and the seat sleeve 12. The shaft sleeve 11 is screwed 16 and gasket 15, insulating backing plate 10b and seat cover 12 are fixed, and the joint of its axle sleeve 11 and screw 16 is provided with insulating ring sleeve 13, and its axle sleeve 11 and seat cover 12 joints are provided with insulating sheath 14. In order to improve the service life of the bearing and keep away from the erosion of lubricating oil, the bearing part is usually insulated to cut off t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com