Magnetic composite oxides preparation method and use of magnetic composite oxides as anionic pollutant absorbent

A technology of anionic pollutants and composite oxides, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems such as waste of energy, achieve shortened reaction cycles, easy transfer and transportation, and easy regeneration and the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

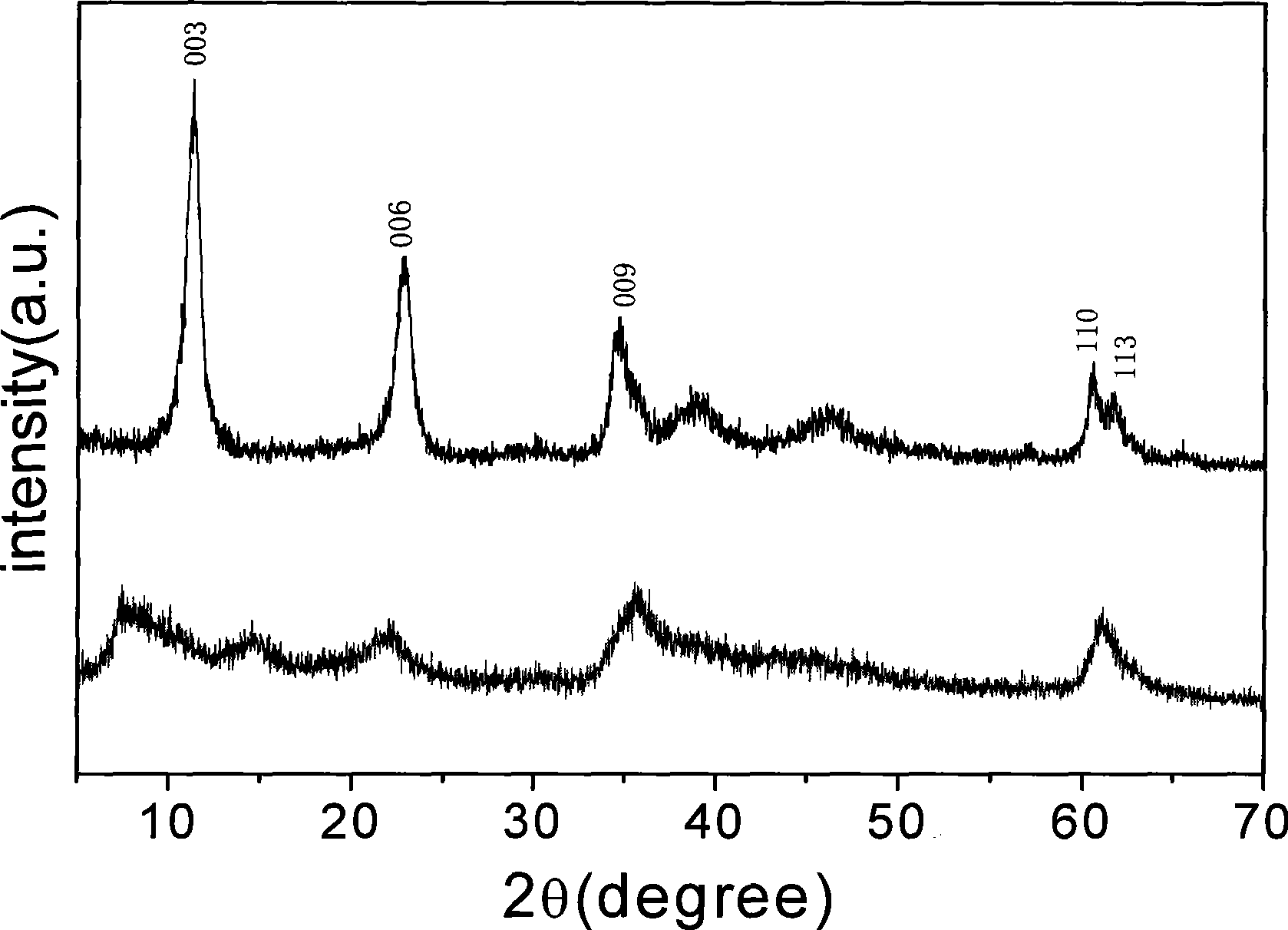

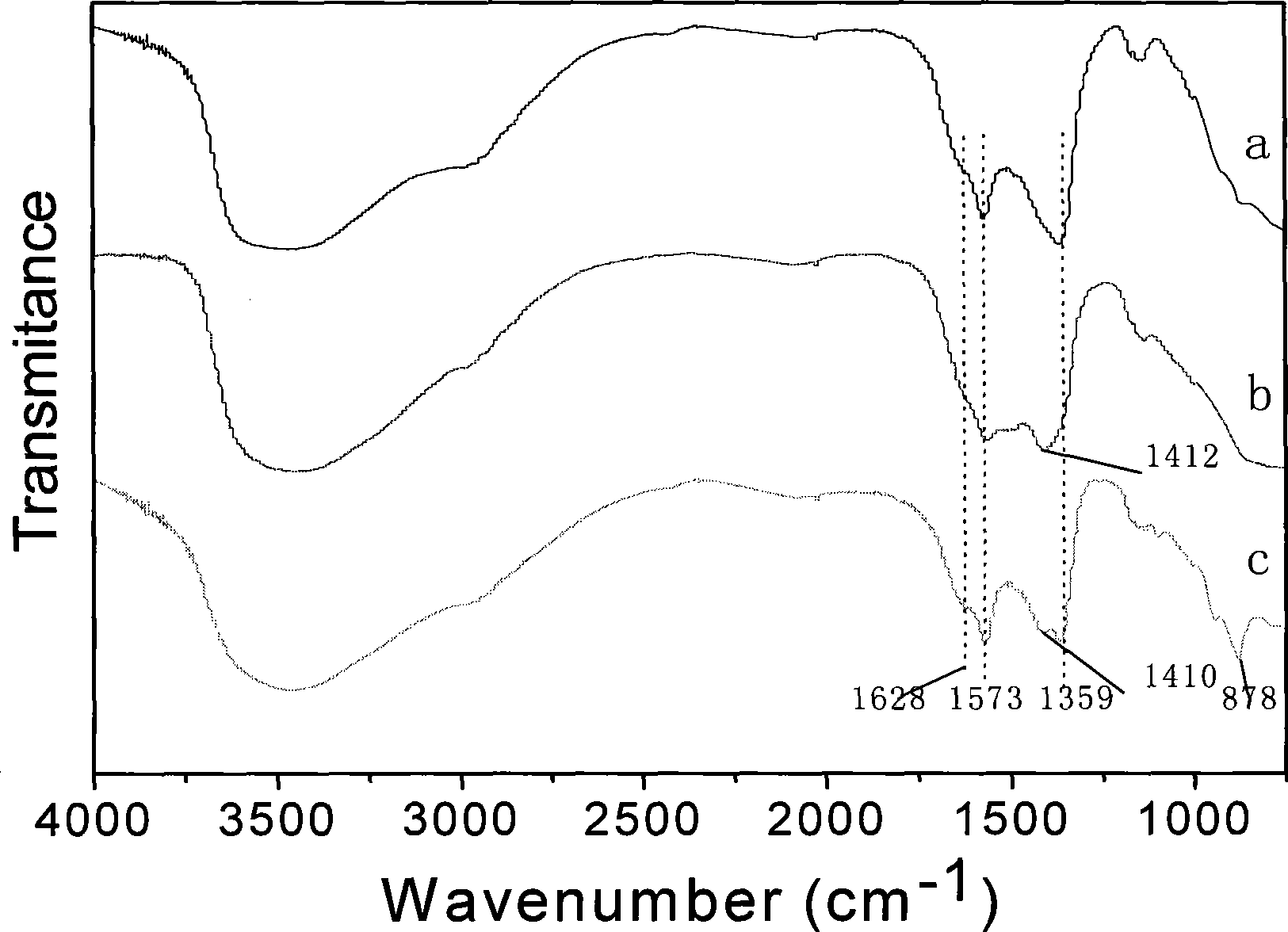

[0018] n(FeSO 4 ·7H 2 O):n(Fe 2 (SO 4 ) 3 ·XH 2 (0)=1:2 prepare 100mL aqueous solution, add this solution into a 500mL three-necked flask, control the temperature to (338±5)K, under vigorous stirring, add dropwise a volume fraction of 20% ammonia water until the pH is 10±5 1. Keep the temperature and age for 10-120 minutes after dropping, use a magnetic field to pull and pour off the supernatant, and the remaining substances are washed repeatedly with distilled water until neutral, and then set aside.

[0019] At room temperature, a certain amount of Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is prepared into 300mL of nitrate aqueous solution, and another certain amount of NaOH and Na 2 CO 3 Prepared into 300mL alkali solution, where n(OH-) / [n(Mg 2+ )+n(Al 3+ )]=2.2, n(CO 3 2- ) / [n(Mg 2+ )+n(Al 3+ )]=0.667. Add the above-mentioned lye and salt solution into a 1000mL three-necked bottle with a certain volume of magnetic medium at the same time at a constant r...

Embodiment 2

[0022] Change Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 The molar ratio of O and other experimental conditions are the same as in Example 1, and hydrotalcite materials with different Mg / Al molar ratios can be prepared.

Embodiment 3

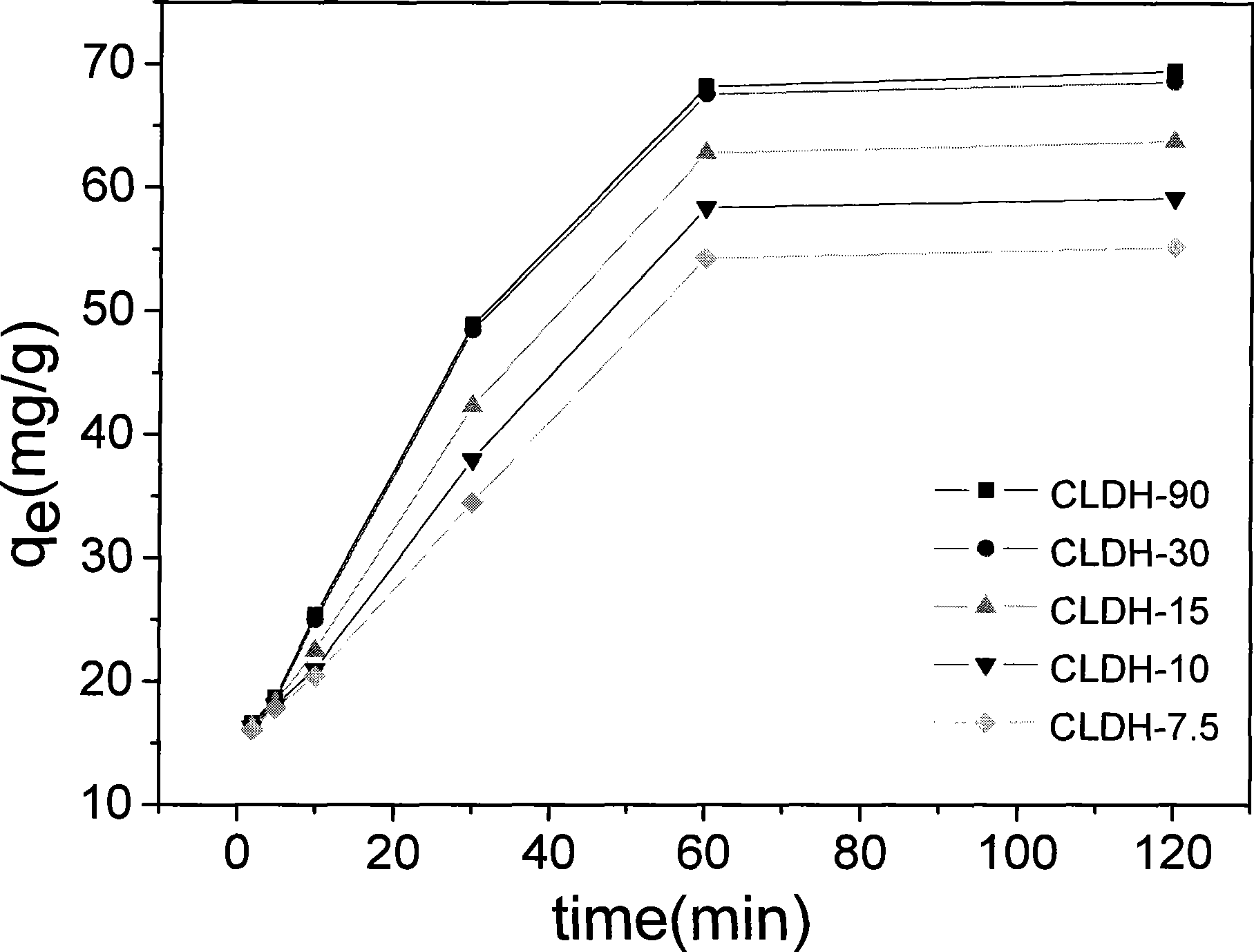

[0024] Change the volume of the magnetic medium added to 5mL, 10mL, 20mL, 50mL, and 100mL to obtain hydrotalcites with different magnetic strengths. According to different Mg 2+ / Fe 2+ Than define hydrotalcite as LDH-X and calcined hydrotalcite as CLDH-X. where X is Mg 2+ / Fe 2+ Compare.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com