Control method and system of zero-spark high-pressure electrostatic precipitation power-supply

An electrostatic dust removal and control system technology, applied in the direction of power supply technology, electrostatic separation, etc., can solve the problems of dust removal voltage adjustment, dust removal efficiency drop, electrode damage, etc., and achieve the effect of increasing detection speed, improving dust removal efficiency, and realizing real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but it does not limit the claims of the present invention.

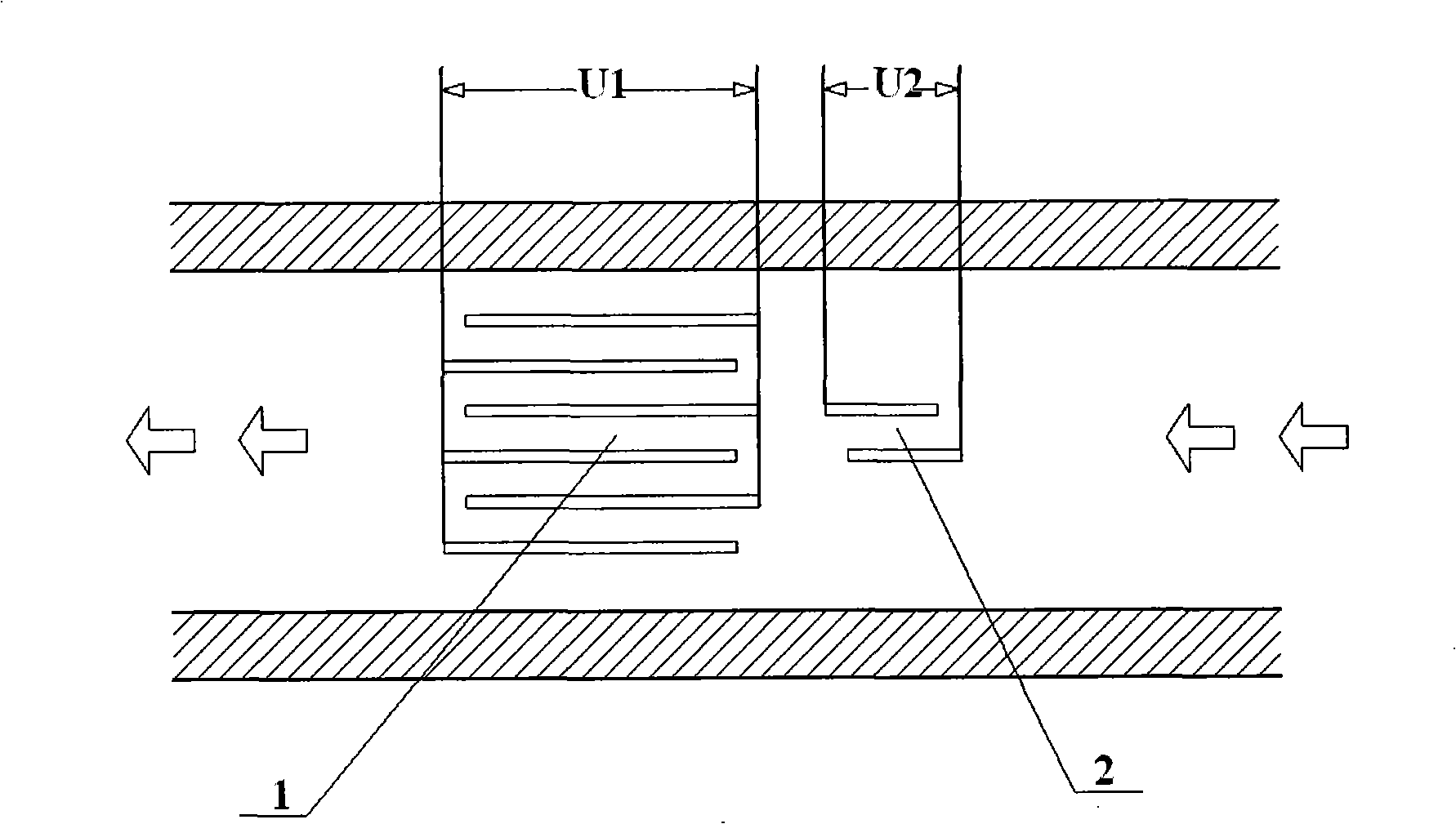

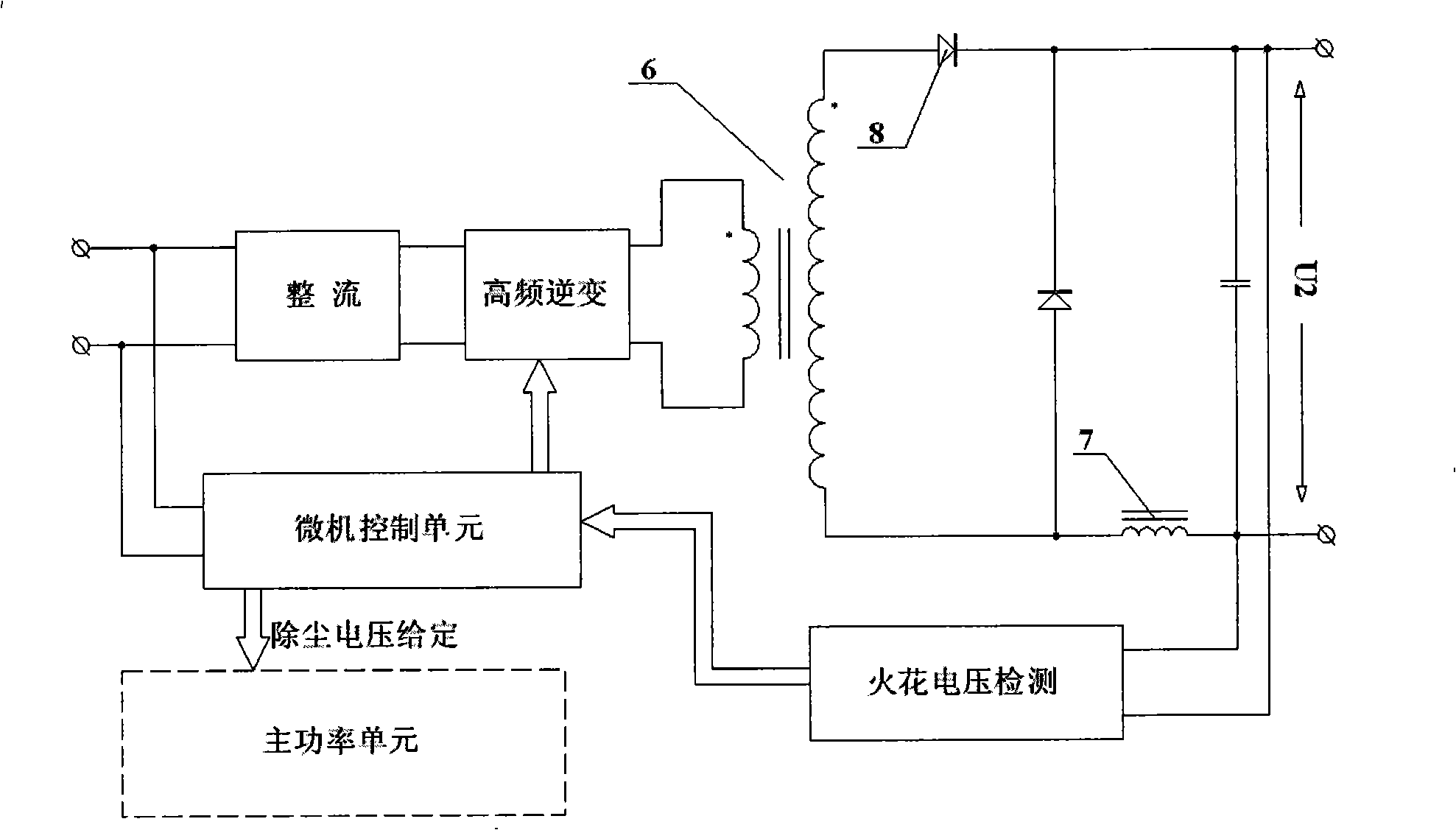

[0040] As shown in the figure, 1 is the dust removal electrode, 2 is the additional detection electrode, 3 is the high-frequency transformer, 4 is the inductor, 5 is the high-voltage silicon stack of the dust removal power supply, 6 is the high-frequency transformer, 7 is the inductor, and 8 is the spark voltage generation High voltage silicon stack of circuit cells.

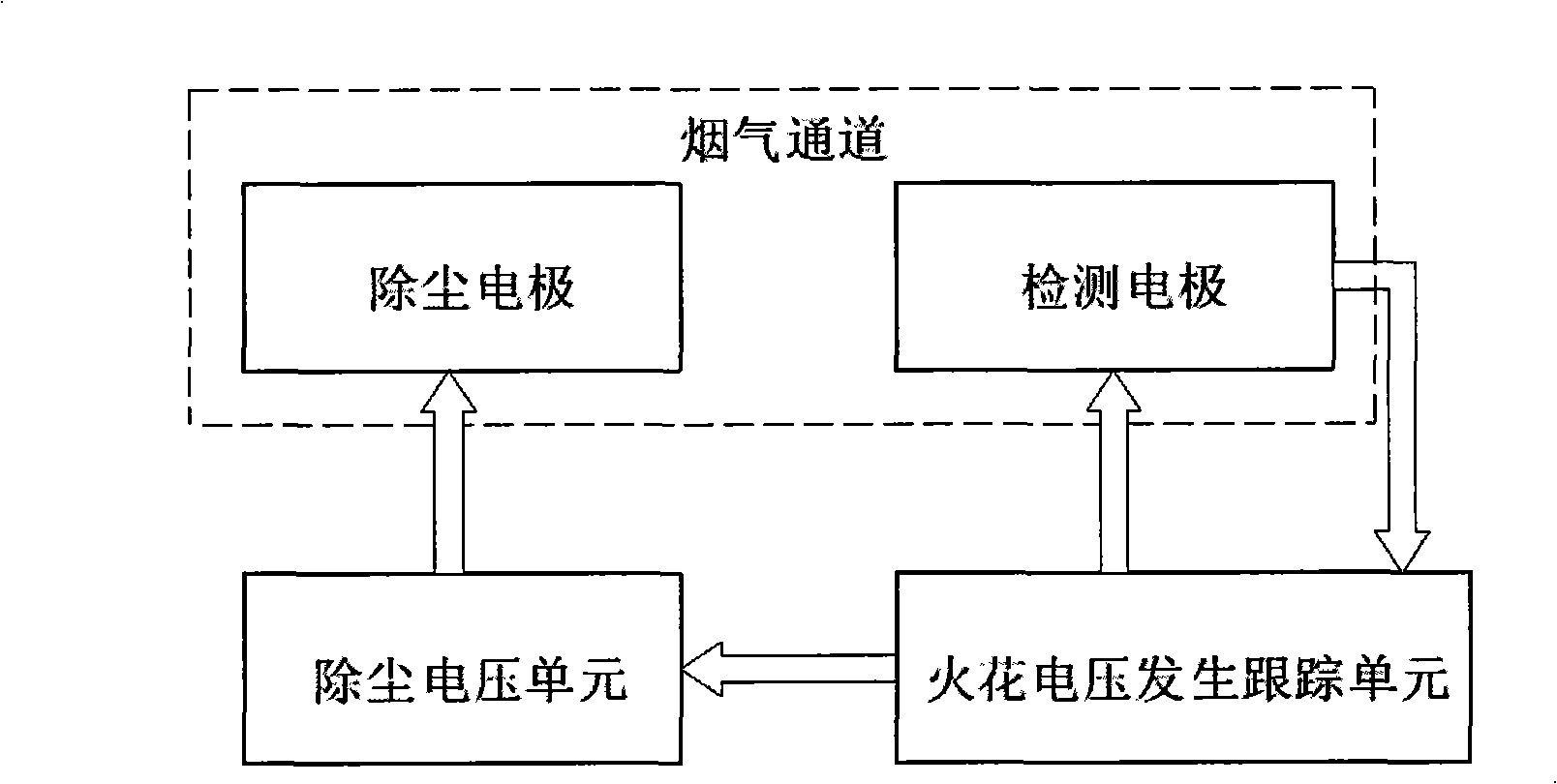

[0041] The dust removal voltage circuit unit and the spark voltage detection unit constitute a complete electrostatic dust removal power supply system.

[0042] The specific composition of the microcomputer controller is: microprocessor (CPU).

[0043] An analog-to-digital conversion unit (AD) is used to convert the collected analog voltage of the additional electrode into a digital value for processing by the CPU.

[0044] The digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com