System and method for applying LNG cold energy to butyl rubber synthesis

A technology of butyl rubber and cold energy, applied in the method of container discharge, equipment discharged from pressure vessels, pressure vessels, etc., to achieve the effects of simplifying the refrigeration process, reducing production power consumption, and high-grade cold energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

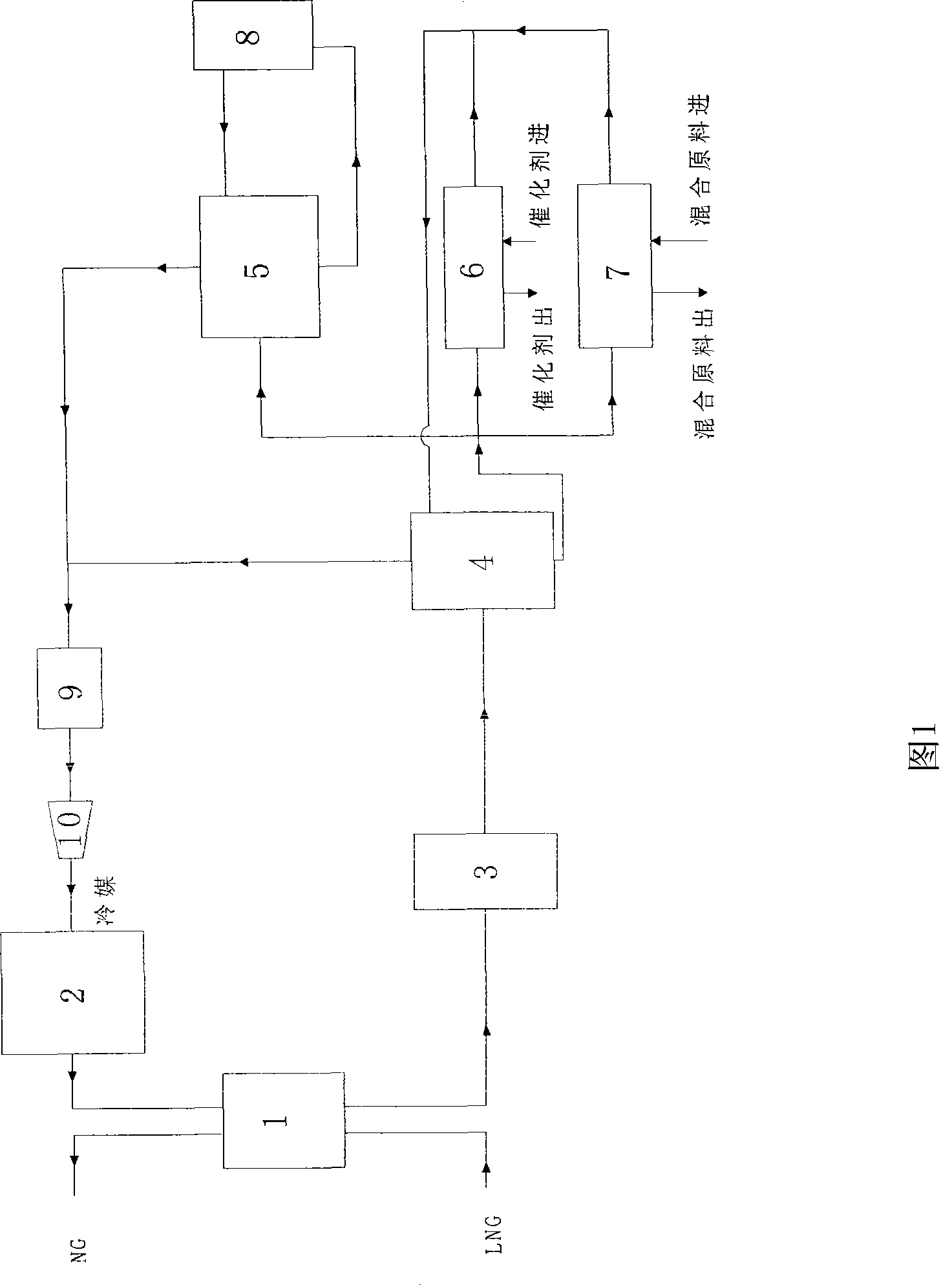

[0036] Basic LNG cold energy using ethane as refrigerant for butyl rubber synthesis refrigeration system and process

[0037] As shown in Figure 1 of the attached drawing of the specification, the system mainly includes:

[0038] LNG heat exchanger 1, gaseous refrigerant buffer tank 2, liquid refrigerant storage tank 3, flash tank A-4, flash tank B-5, catalyst heat exchanger 6, raw material heat exchanger 7, polymerization tank heat exchanger 8 , Air cooler 9, compressor 10.

[0039] Its workflow is:

[0040] The LNG and the gaseous ethane from the gaseous refrigerant buffer tank 2 exchange heat in the LNG heat exchanger 1 , the LNG is vaporized into NG and heated to normal temperature, and the gaseous ethane is directly condensed into a liquid state and then enters the liquid refrigerant storage tank 3 .

[0041] The liquid ethane in the liquid refrigerant storage tank 3 enters the flash tank A-4, the pressure is adjusted to -49KPa(G), and the temperature of the liquid ethane...

Embodiment 2

[0048] The basic LNG cold energy with ethylene as refrigerant is used in butyl rubber synthetic refrigeration system and process.

[0049] As Fig. 1, its system equipment is the same as embodiment 1.

[0050] Its workflow is:

[0051] LNG and gaseous ethylene from the gaseous refrigerant buffer tank 2 exchange heat in the LNG heat exchanger 1, the LNG is vaporized into NG and heated to normal temperature, and the gaseous ethylene is directly condensed into a liquid state and enters the liquid refrigerant storage tank 3.

[0052] The liquid ethylene in the liquid refrigerant storage tank 3 enters the flash tank A-4, the pressure is adjusted to 24KPa(G), and the temperature of the liquid ethylene in the flash tank A-4 is controlled to be about -100°C.

[0053] Part of the liquid ethylene at -100°C in the flash tank A-4 enters the catalyst heat exchanger 6 at a controlled flow rate to cool the catalyst solution and return to the flash tank A-4 after being vaporized. The catalys...

Embodiment 3

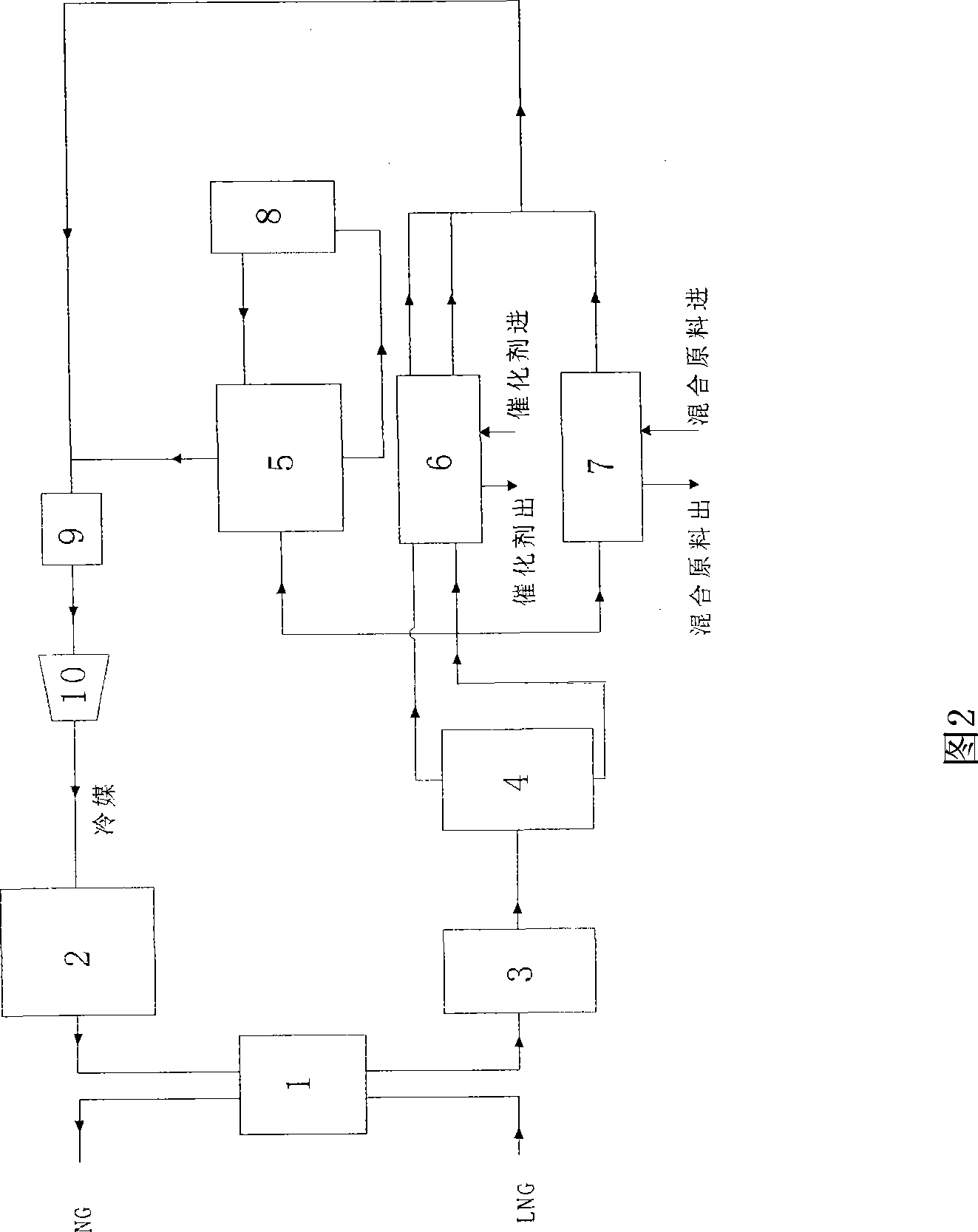

[0059] The improved and optimized LNG cold energy using ethylene as refrigerant is used in butyl rubber synthesis refrigeration system and process;

[0060] Refer to accompanying drawing 2 of the description, and Fig. 2 is a flow chart of improving and optimizing LNG cold energy for butyl rubber synthesis refrigeration on the basis of Example 2. The difference from Example 2 is that the sensible heat of low-temperature gaseous ethylene is fully utilized when cooling the catalyst solution and mixing raw materials.

[0061] In Figure 2, the gaseous ethylene at -100°C and part of the liquid ethylene at -100°C in the flash tank A-4 control the flow rate and enter the catalyst heat exchanger 6 to cool the catalyst solution and then vaporize and heat up to gaseous ethylene slightly lower than the initial temperature of the catalyst solution , the catalyst solution is cooled to the temperature required for the butyl rubber synthesis process;

[0062] Part of the liquid ethylene in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com