A device and production method for producing ultra-high-purity carbon dioxide by heat pump rectification

A carbon dioxide, heat pump rectification technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex process flow, strong adaptability, complex process, etc., achieve simple process flow, improve utilization efficiency, improve The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

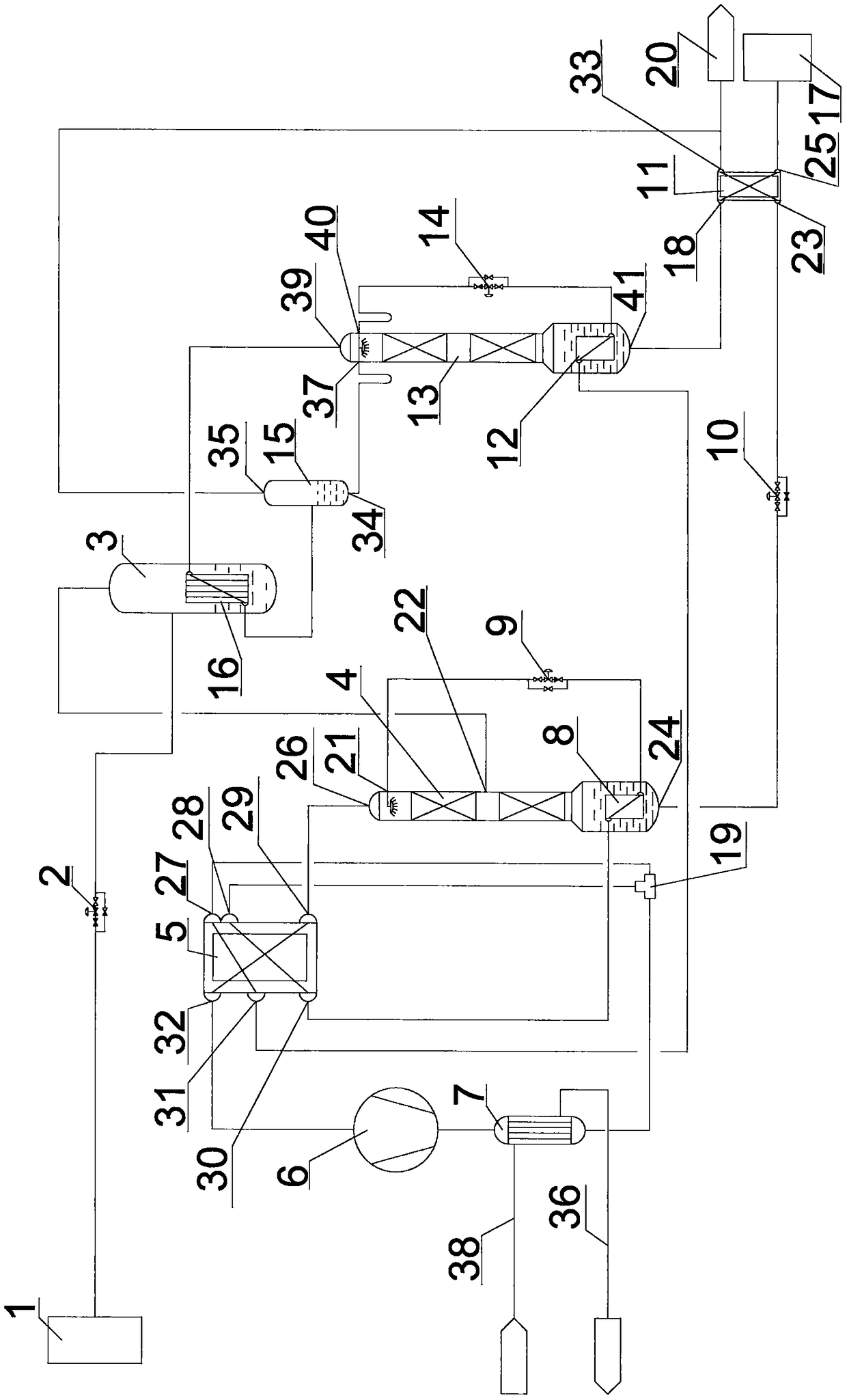

[0032] A device for producing ultra-high-purity carbon dioxide by heat pump rectification, including a raw material liquid storage tank 1, the raw material liquid storage tank 1 passes through the first throttling valve group 2 and the evaporator 3 and the first raw material gas inlet of the first rectification tower 4 22, the gas phase outlet 26 at the top of the first rectification tower 4 passes through the first feed gas inlet 29 of the second heat exchanger 5, the first feed gas outlet 32 of the second heat exchanger 5, the heat pump 6 and the third heat exchanger in sequence. The tube side of the heat exchanger 7 is connected with the first three-way 19, and the second end of the first three-way 19 passes through the third raw gas inlet 27 of the second heat exchanger 5 and the third raw gas outlet of the second heat exchanger 5 31 is connected with the inlet of the second reboiler 12 at the bottom of the second rectification tower 13, and the outlet of the second reboi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com