Lithium-sulfur primary battery cathode material and preparation method thereof

A battery positive electrode and positive electrode material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low sulfur active material utilization, low active material load, open circuit voltage drop, etc., to promote the transmission of ions and electrons , easy strategy, enhanced stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

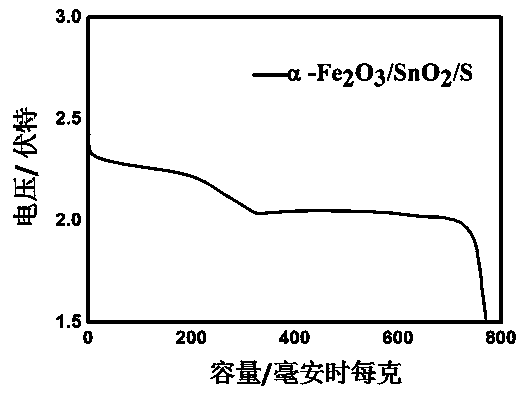

[0026] The positive electrode material of the lithium-sulfur primary battery is α-Fe 2 o 3 / SnO 2 Composite materials formed by nanomaterials and S. said

[0027] α-Fe 2 o 3 / SnO 2 Nanomaterials are composite heterostructures.

[0028] According to the mass ratio of α-Fe2 o 3 / SnO 2 Nanomaterials: S is 1:3.

[0029] The composite material is prepared by combining the chemical vapor deposition method and the hydrothermal method.

[0030] The preparation method of the positive electrode material of the lithium-sulfur primary battery comprises the following steps:

[0031] (1) SnO 2 Preparation of nanowires: mix SnO with a mass ratio of 1:1 2 The powder and graphite powder were ground and mixed and transferred to a porcelain boat, and then the stainless steel substrate and the porcelain boat coated with Au sputtering were placed in a quartz tube, wherein the center of the porcelain boat was located in the center of the quartz tube, and the stainless steel substrate su...

Embodiment 2

[0037] The preparation method of the positive electrode material of the lithium-sulfur primary battery comprises the following steps:

[0038] (1) SnO 2 Preparation of nanowires: mix SnO with a mass ratio of 1:1 2 The powder and graphite powder were ground and mixed and transferred to a porcelain boat, and then the stainless steel substrate and the porcelain boat coated with Au sputtering were placed in a quartz tube, wherein the center of the porcelain boat was located in the center of the quartz tube, and the stainless steel substrate substrate Placed downstream of the argon flow; the furnace temperature was raised to 1050 °C at a rate of 50 °C / min, and heated at 1050 °C for 1 h under constant conditions of 50 sccm argon flow and 15 mbar pressure; after cooling to room temperature, SnO 2 nanowires were deposited on stainless steel substrates to obtain deposited SnO 2 Nanowires;

[0039] (2) α-Fe 2 o 3 / SnO 2 Preparation of nanomaterials: the prepared SnO 2 The stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com