PVC furniture leather and method for producing the same

A manufacturing method and technology of furniture leather, applied in the direction of textiles and papermaking, etc., can solve the problems of low processability and effective use rate, large difference in warp and weft elongation, and low elongation of ordinary base fabrics, etc. , to achieve the effect of reducing the pasting process, ensuring the hand feel and improving the hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

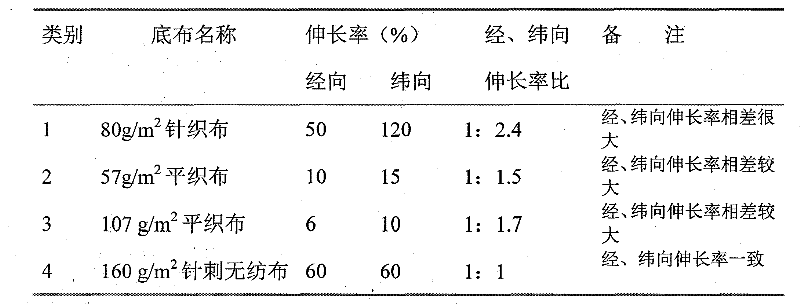

[0024] A PVC furniture leather, the base fabric is 2.5D×51mm or 2.5D×38mm polyester staple fiber needle punched non-woven fabric prepared as raw materials, and its weight is 130-180g / m 2 , The resin layer is PVC resin.

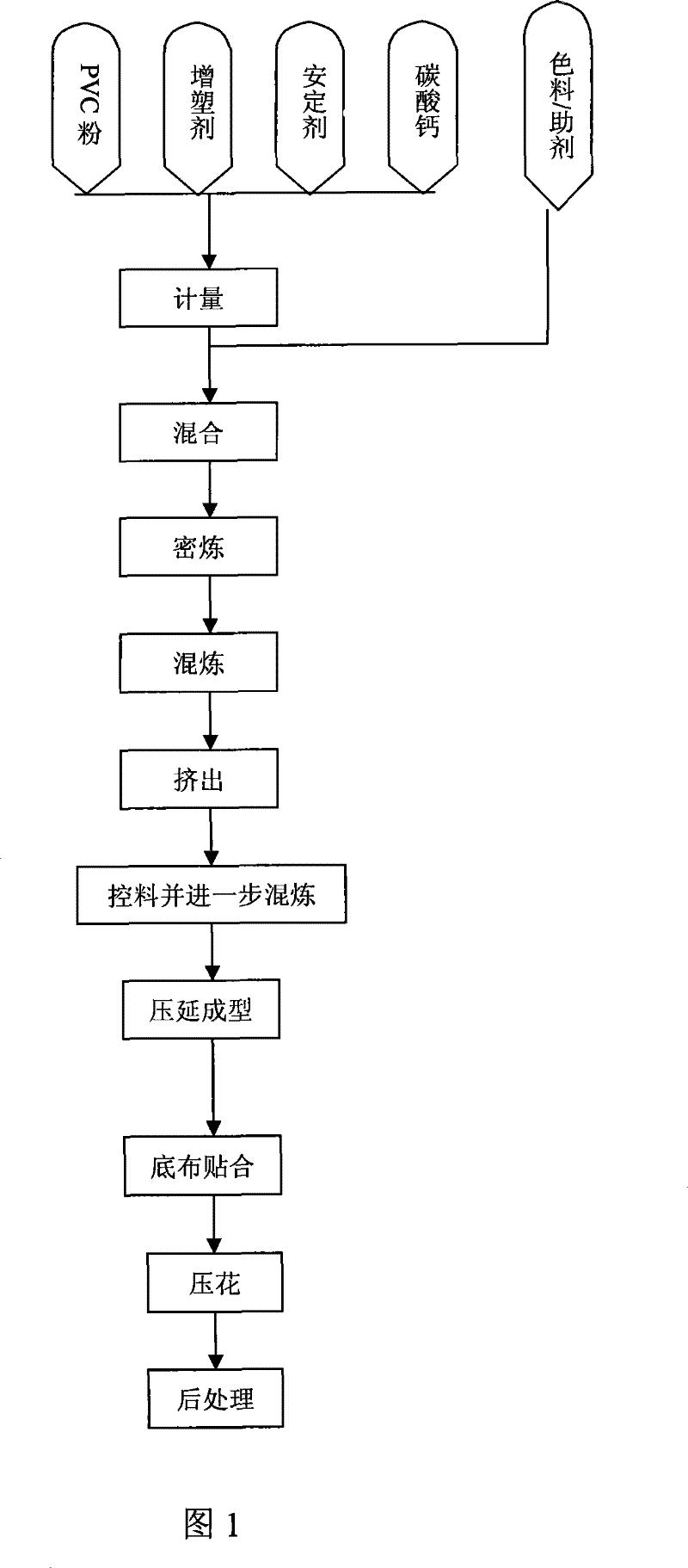

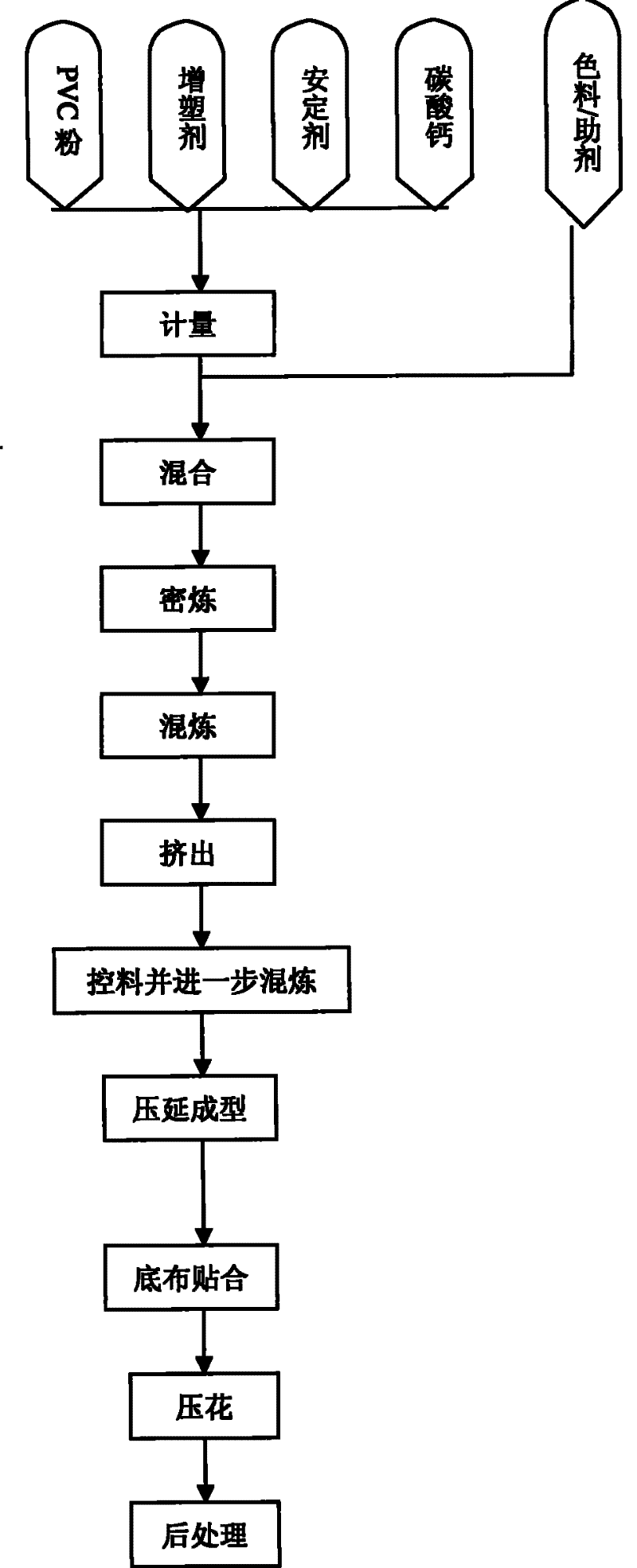

[0025] Its manufacturing method see figure 1 .

[0026] Use an automatic metering system to measure PVC powder, plasticizer, stabilizer, and calcium carbonate, and then stir in the mixing tank at high speed for 5min-7min. This step controls the material temperature at 95℃-105℃.

[0027] Then add color materials or additives and mix for 4.5min-5.5min in a 10,000-horsepower machine. In this step, the temperature of the material is controlled at 150°C.

[0028] Then it is mixed in the second rolling mill. This step controls the material temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com