Middle-storage low speed coal mill load switch control method

A technology of steel ball coal mill and control method, applied in the direction of adaptive control, electric controller, electrical program control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

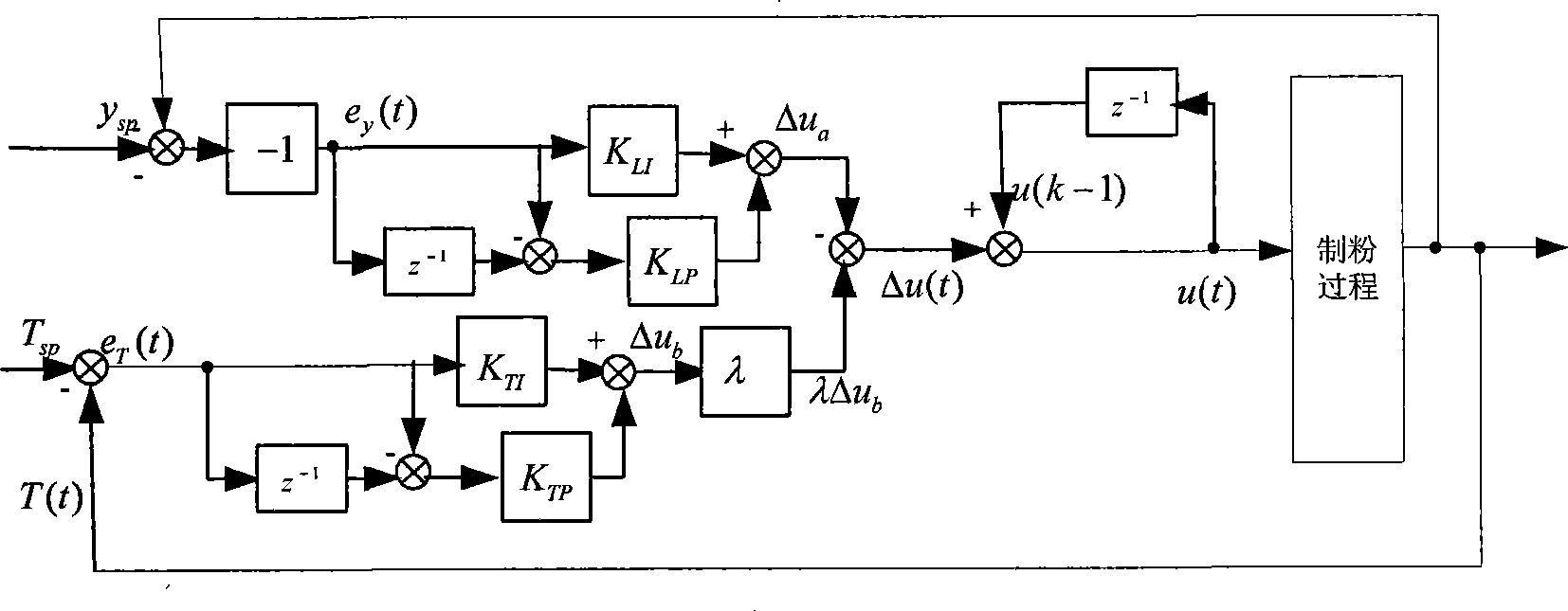

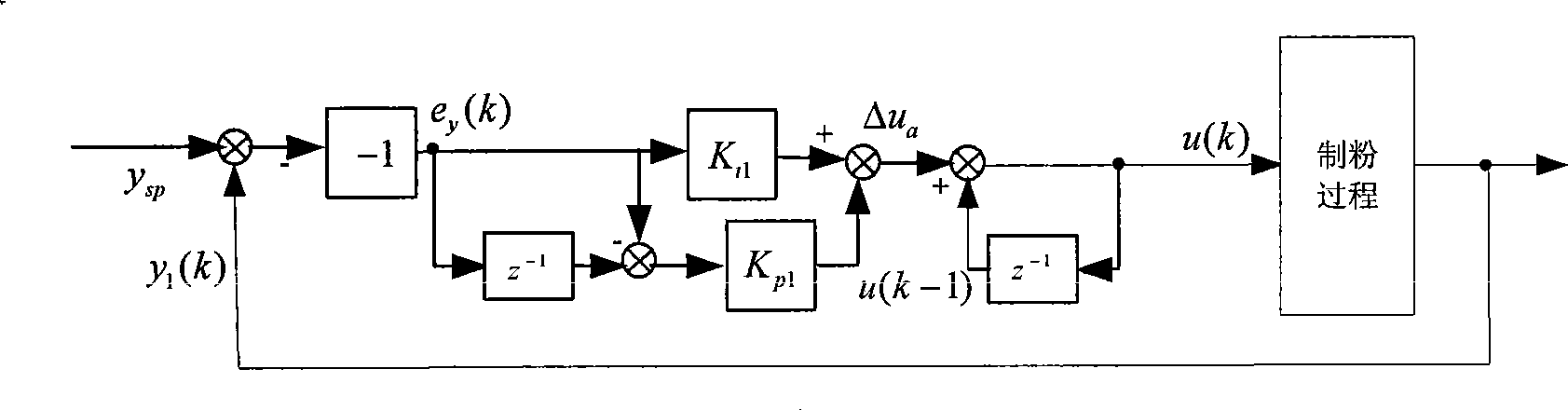

Method used

Image

Examples

Embodiment Construction

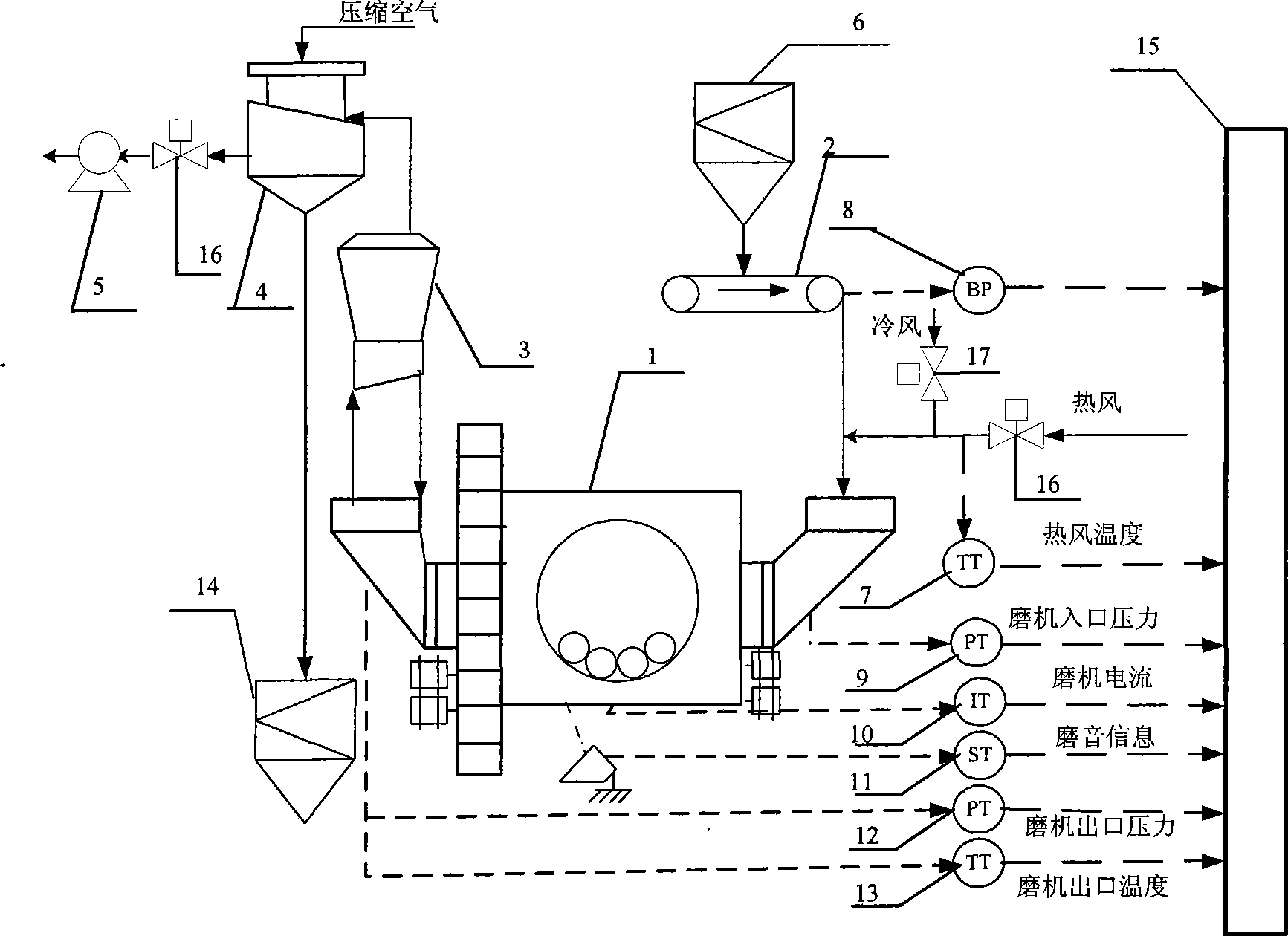

[0065] The load switching method of the mill is applied to the alumina rotary kiln pulverization system of an aluminum plant in China in conjunction with the accompanying drawings, and the load switching control method of the intermediate storage steel ball coal mill of the present invention is further described.

[0066] like figure 1 As shown, the pulverizing system adopted provides qualified pulverized coal for the combustion of the rotary kiln, and produces pulverized coal by using the waste heat generated by clinker cooling. In the load control of the coal mill, since the waste heat of sintering is used to produce pulverized coal, the temperature of the hot air is low and changes frequently, so the cold air door is usually fully closed and the hot air door is fully opened, so that the system can obtain the maximum heat energy, mainly by adjusting the speed of the coal feeder Control mill load.

[0067] The specification of the steel ball coal mill is Φ3.2×9.5m, the desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com