Process for producing hexa-sulphonic acid liquid fluorescent whitening agents

A technology of fluorescent whitening agent and hexasulfonic acid, which is applied in the field of special additives for papermaking, can solve the problems of insufficient reactivity, dark paper surface, low maximum whiteness, etc., to save raw material consumption, improve poor stability, Good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

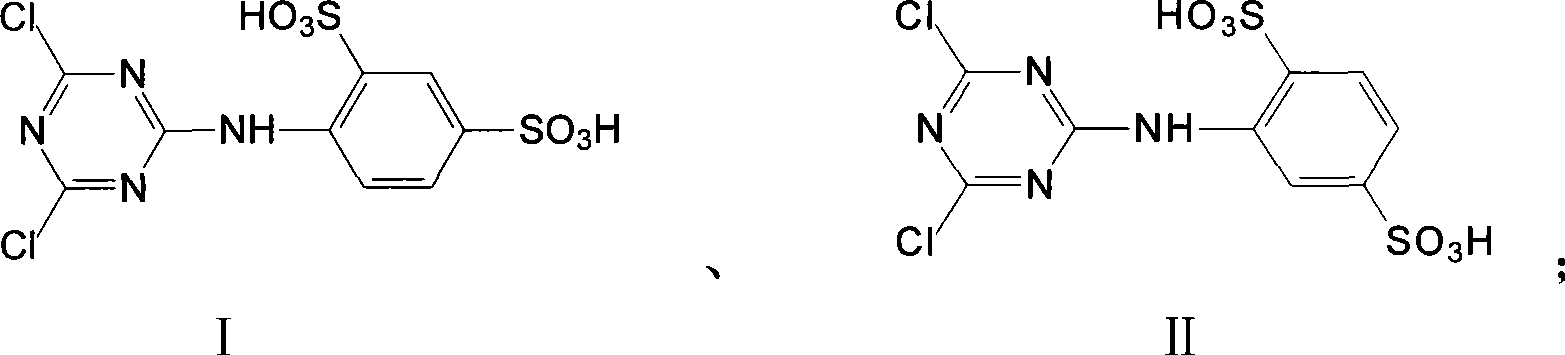

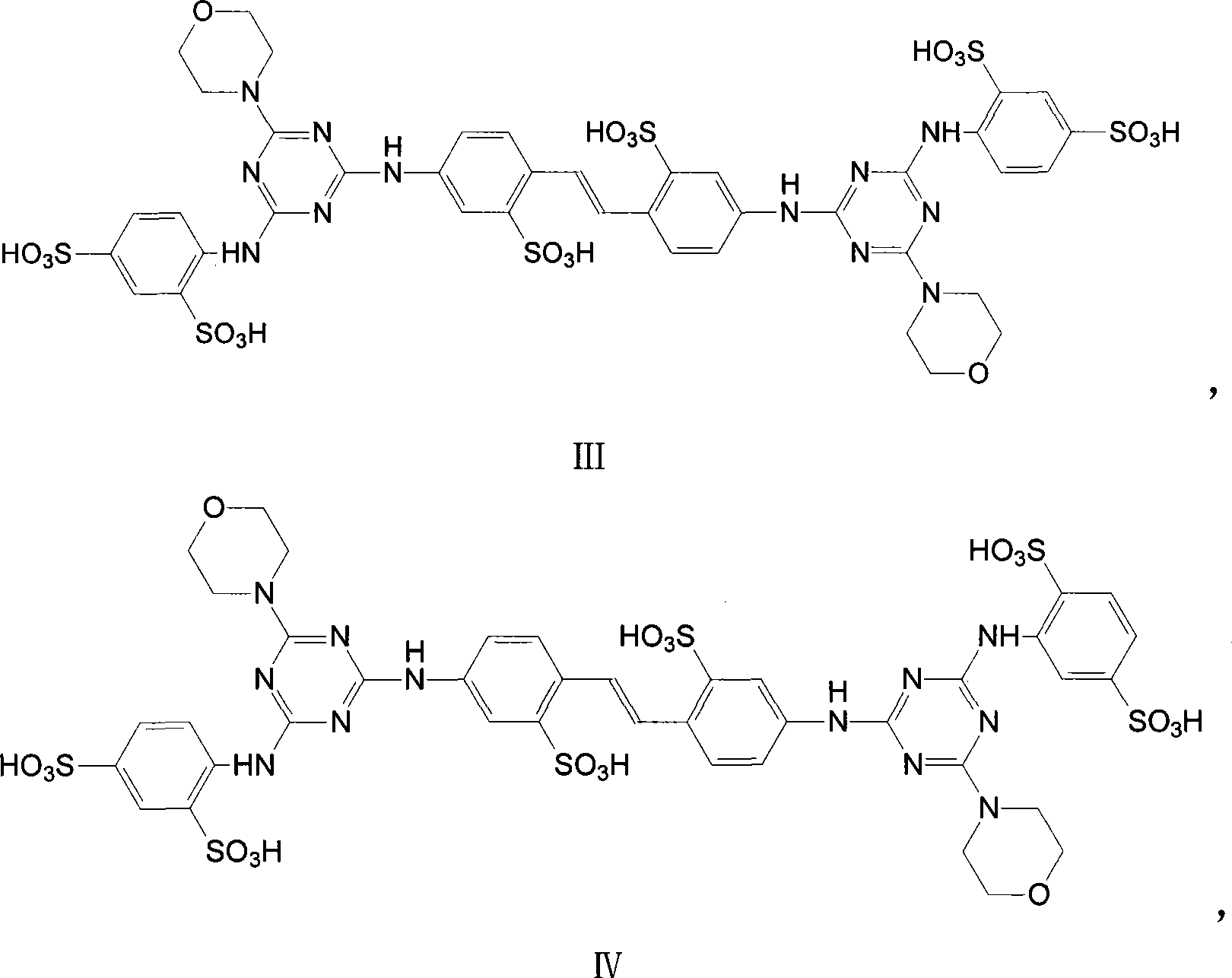

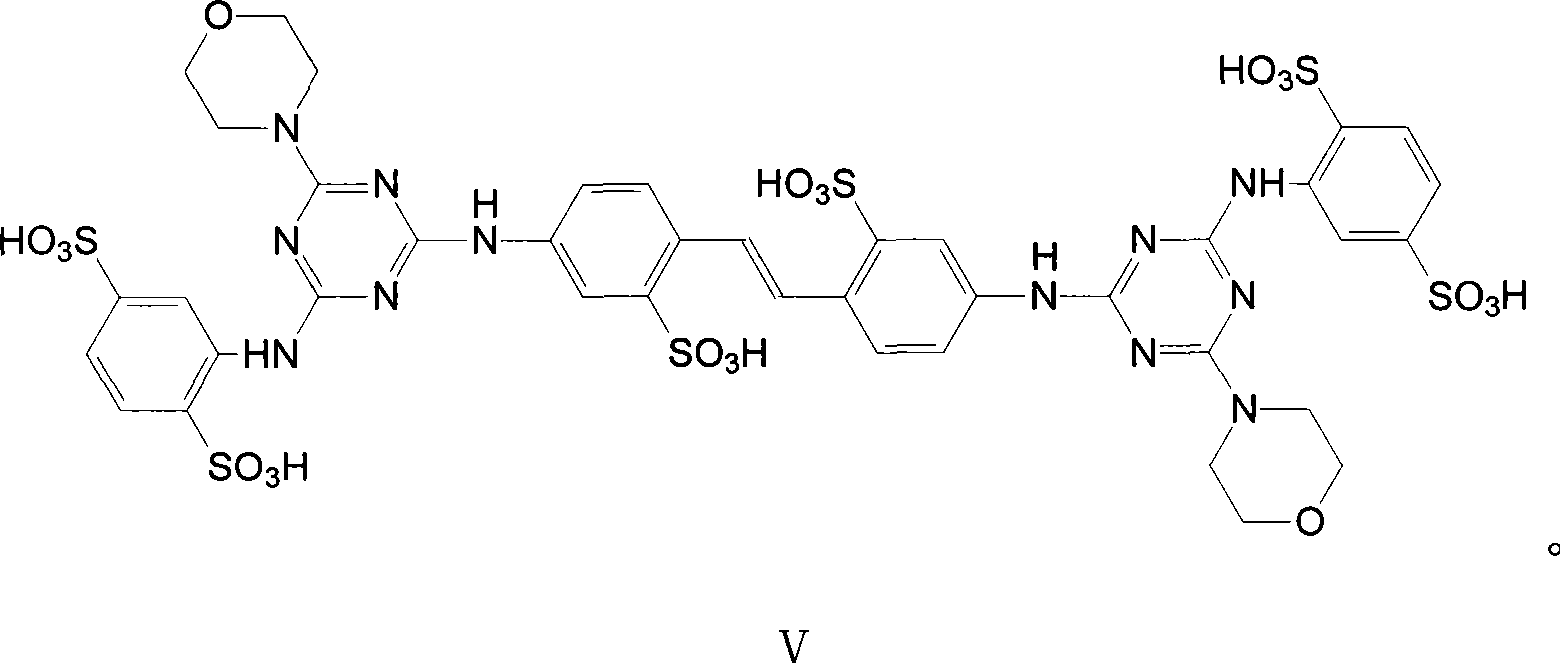

Method used

Image

Examples

Embodiment 1

[0027] Chemical Name Feeding quantity (g) Cyanuric chloride 20 Aniline-2,4 / 5-disulfonic acid (molar ratio 2 / 8) 5.9 / 23.7 DSD acid 19.1 Morpholine 10.8 30% liquid alkali 72

Embodiment 2

[0029] Chemical Name Feeding quantity (g) Cyanuric chloride 20 Aniline-2,4 / 5-disulfonic acid (molar ratio

Embodiment 3

10.4 / 19.2 DSD acid 19.1 Morpholine 10.8 30% liquid alkali 72

[0032] The synthetic steps of three-component hexasulfonic acid liquid optical brightener are as follows:

[0033] (1) One-step reaction: add 300ml of water in a three-necked flask, use an ice bath to cool, and the cooling temperature is 0-4°C, then add cyanuric chloride (hereinafter referred to as CNC), 30% liquid caustic soda and aniline-2,4 -disulfonic acid and aniline-2,5-disulfonic acid are stirred and reacted, the pH value is controlled below 2.5, the temperature is 0-4° C., and the reaction end point is judged by an amino indicator.

[0034] (2) Two-step reaction: Add DSD acid with a molar ratio of 0.47 to CNC, control the pH value to 6.0-7.0, the temperature is 40-50°C, and use the amino indicator to judge the end point.

[0035] (3) Three-step reaction: add morpholine with a molar ratio of 1.15 to CNC, control the pH value at 8.5-10.5, keep the temperature at 90-110° C., and keep war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com