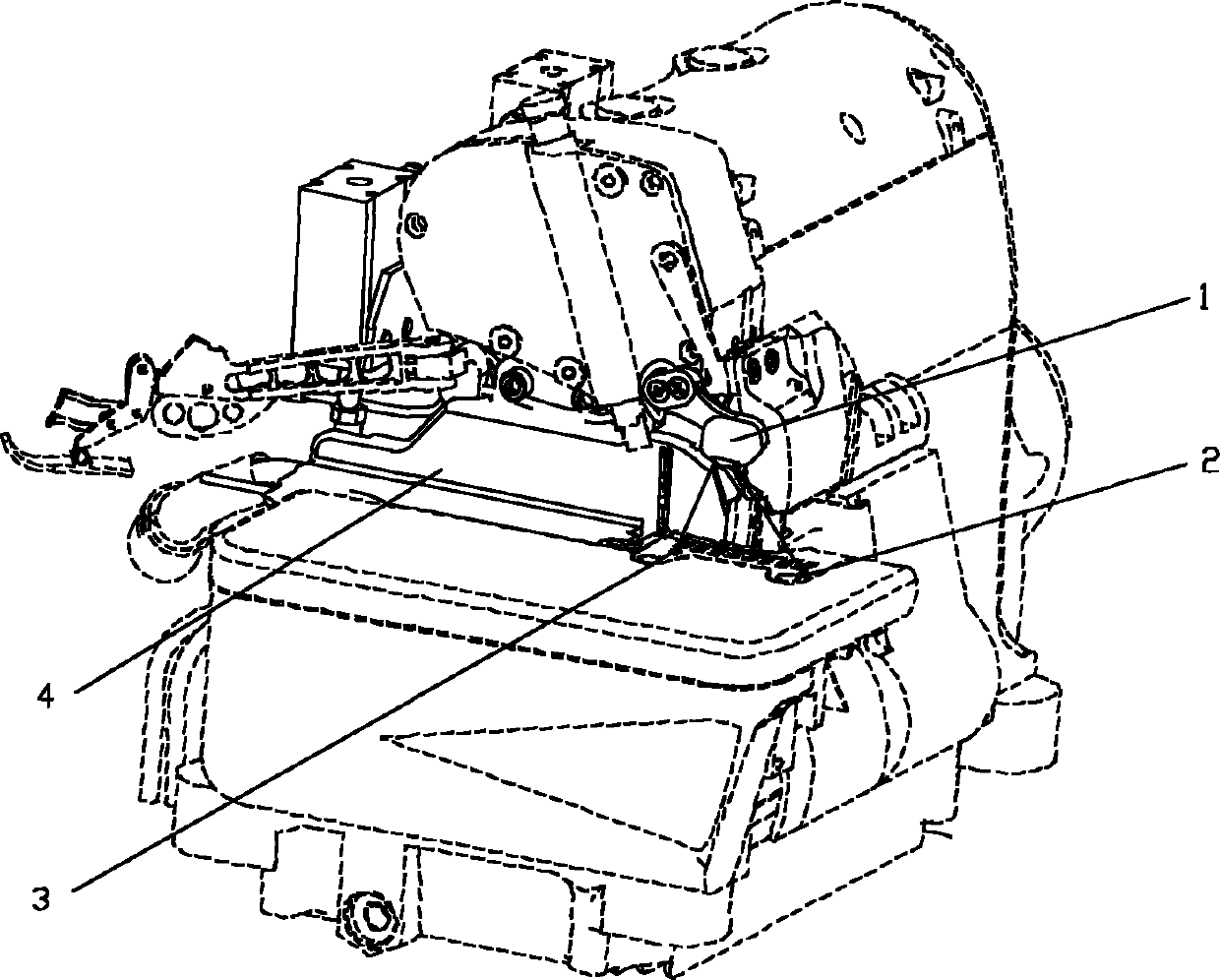

Photoelectronic control system for industrial sewing machine

An industrial sewing machine, photoelectric control technology, applied in the direction of sewing machine control devices, sewing machine components, electrical program control, etc., can solve the problems of lack of automatic detection feedback control, large thickness difference, dusty environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

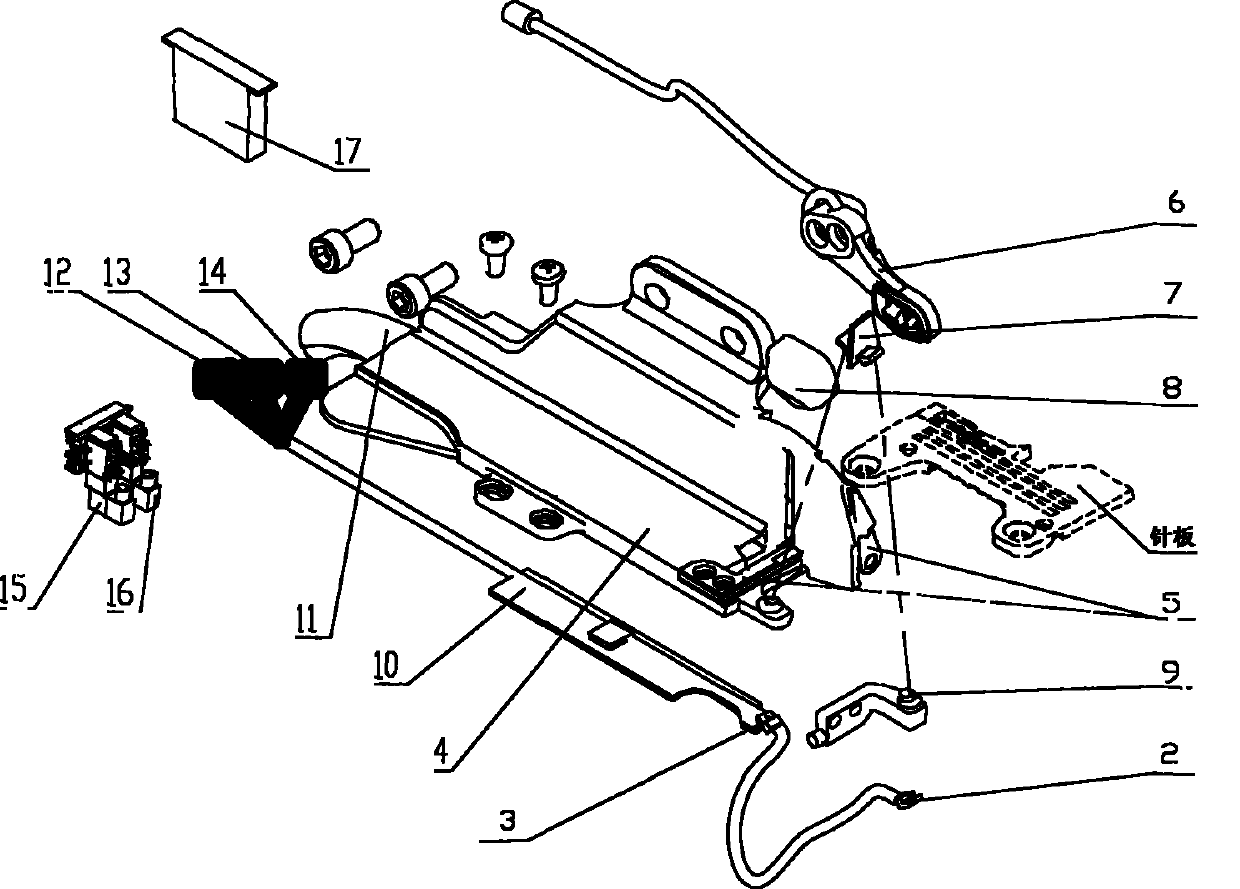

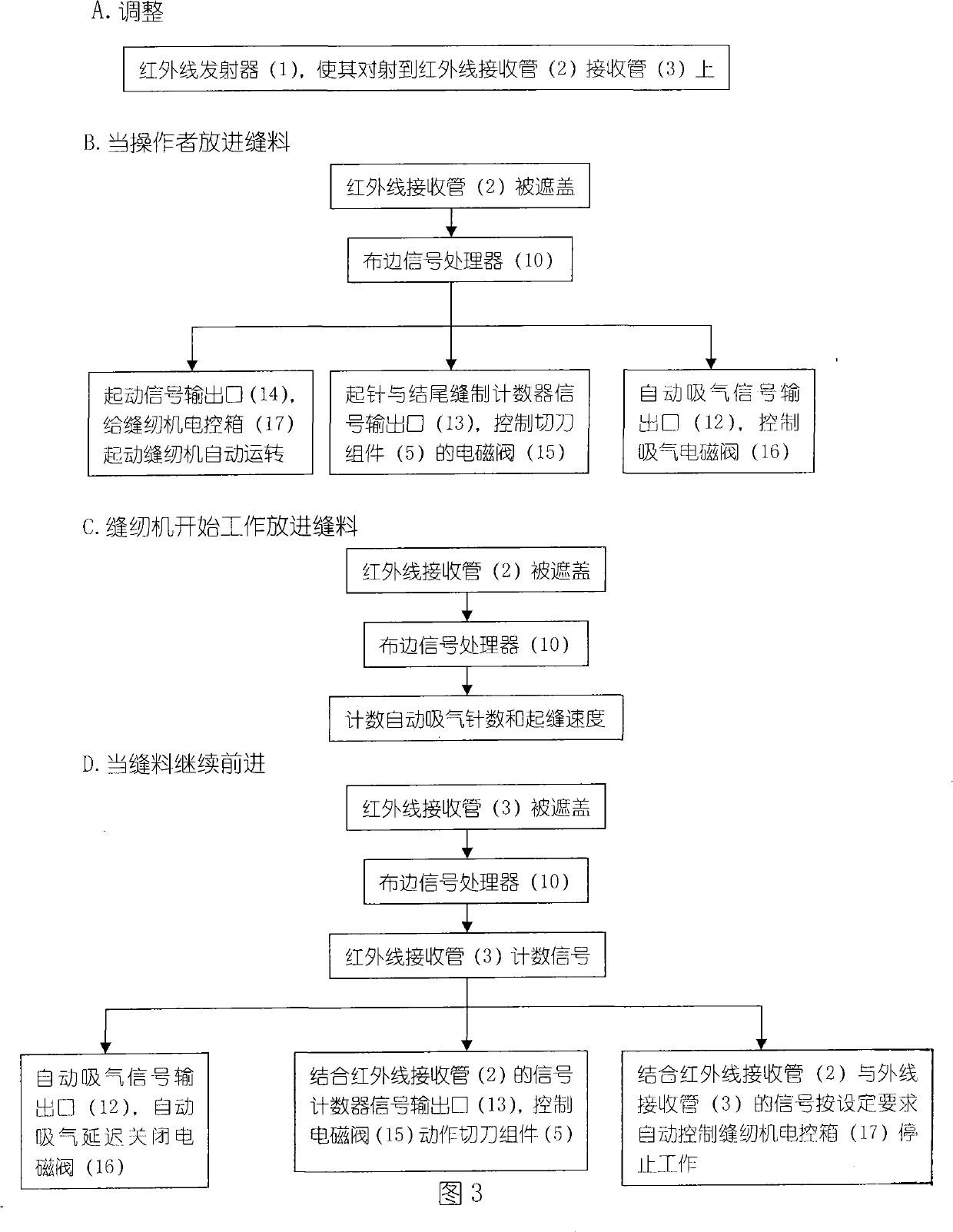

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0010] A photoelectric control system for industrial sewing machines (such as figure 2 Shown) its main structure consists of an upper infrared emitter 1, the infrared emitter 1 has a housing 6 with a mounting handle, the infrared emitting tube is welded on the PBC board 7, and the infrared emitter shell 8 is made of colored PC material that transmits infrared light. Infrared emitter leads form infrared emitter 1, which is installed on the two screw holes beside the sewing machine needle column of the overlock sewing machine, and the two infrared emitting tubes with an angle of 125 degrees shoot down to the two infrared rays in the round hole of the needle plate. receiving tube.

[0011] The infrared receiver 4 is the main casing, the infrared receiver main casing 4 adopts a transparent colored plastic inner right-angle type, and there are two assembly holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com