Automatic control device for greenhouse hot-water heating

An automatic control device, a technology for hot water heating, applied in digital control, electrical program control, household heating and other directions, can solve the problems of large power consumption, uneven indoor temperature field, high equipment requirements, and achieve uniform indoor temperature field. , The effect of reducing labor input and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

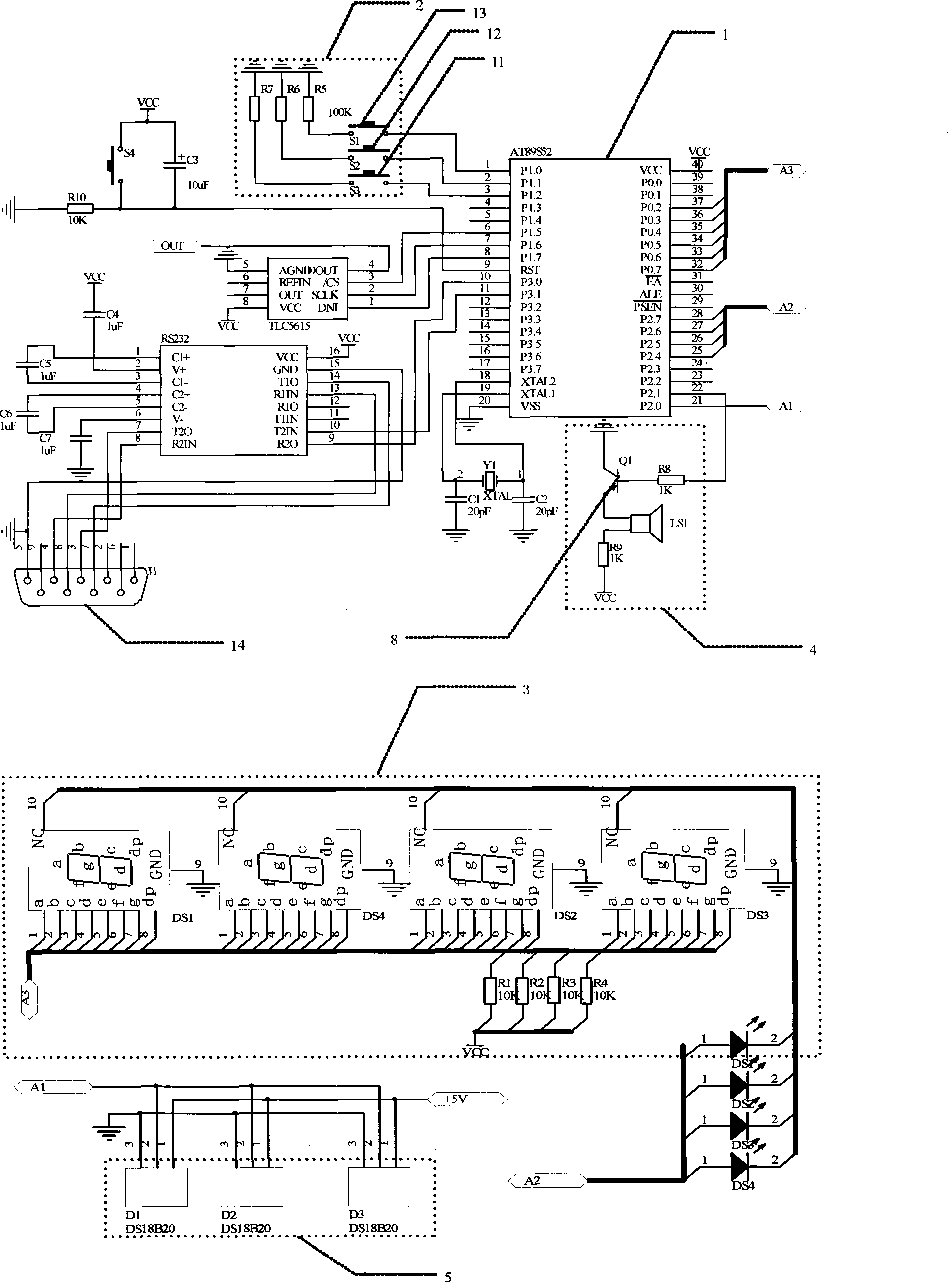

[0016] figure 1 The circuit shown includes three digital temperature sensors D1, D2, D3. Its SDATA end is connected with the P2.0 port of the single-chip microcomputer (CPU), the VCC end is connected with the power supply, and the GND end is grounded.

[0017] The circuit includes a display unit composed of a display digital tube 3, each field position control port of which is connected with the P0 port of the single chip microcomputer 1.

[0018] The circuit includes a customized keyboard 2, and the keyboard 2 is provided with three buttons 11, 12, 13, and each port is connected to the P1.0, P1.1, and P1.2 ports of the single-chip microcomputer 1 respectively.

[0019] The circuit includes a TLC5615 digital-to-analog conversion unit, whose DIN, CLK, and CS are respectively connected to the P1.7, P1.6, and P1.5 ports of the microcontroller 1, and the DOUT end is connected to the output data line to the electric regulating valve actuator.

[0020] The circuit includes an audi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com