Bearing state diagnostic apparatus

A state diagnosis and bearing technology, which is applied in bearing assembly, bearings, measuring devices, etc., can solve the problems of high sensor price, lower S/N ratio, increased assembly man-hours, etc., to reduce the number of sensors, reduce temperature rise, and diagnostic accuracy Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

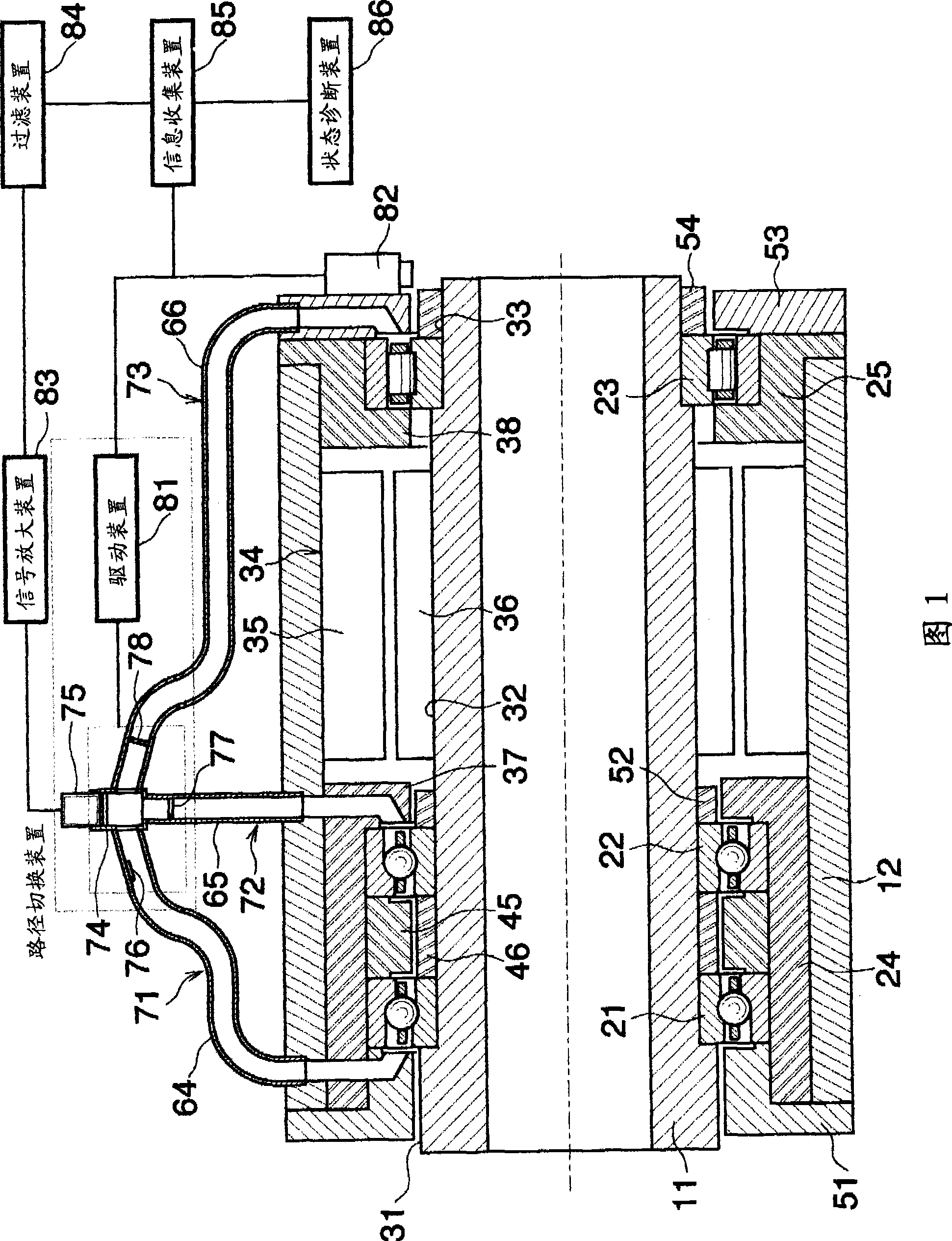

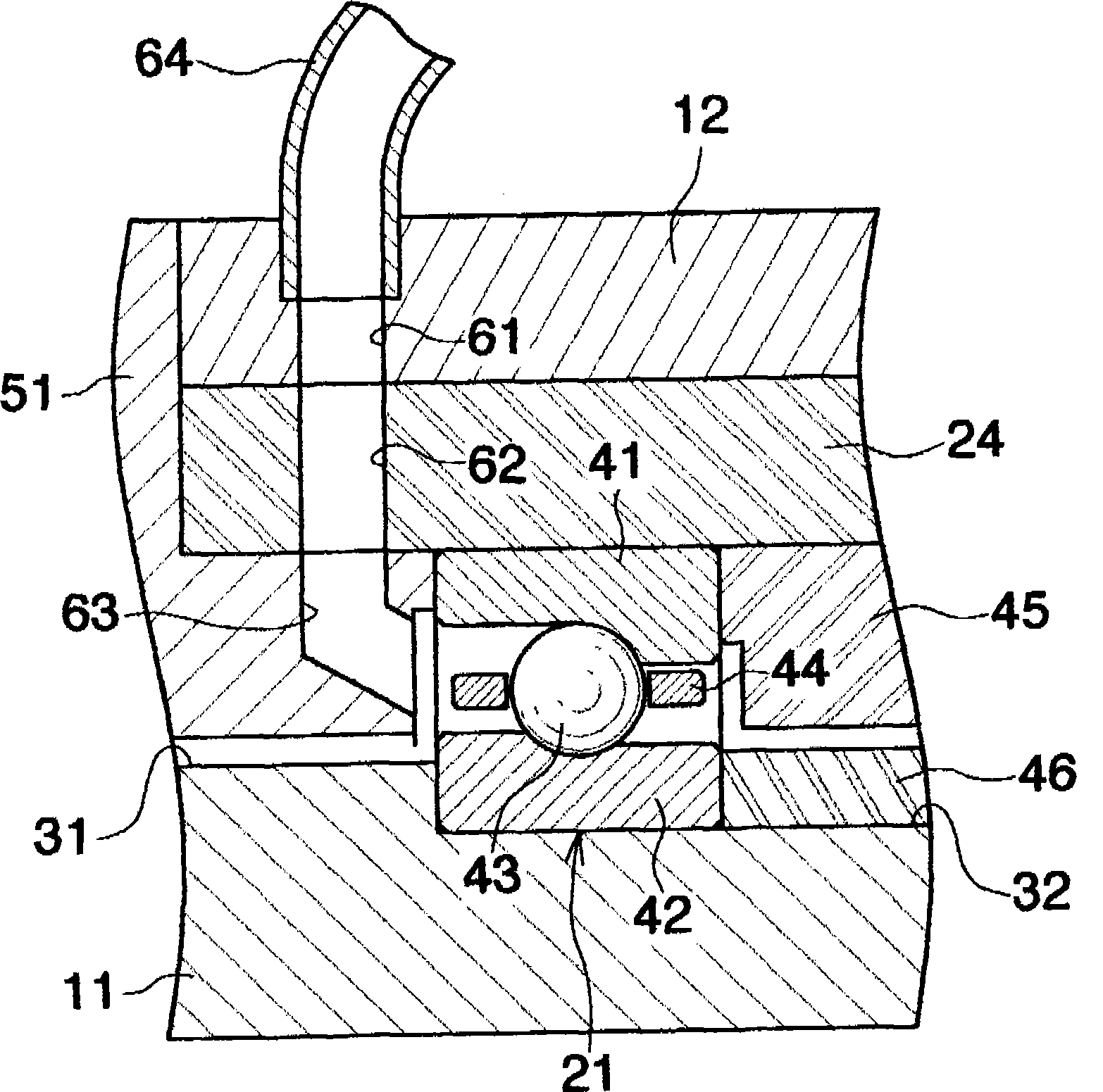

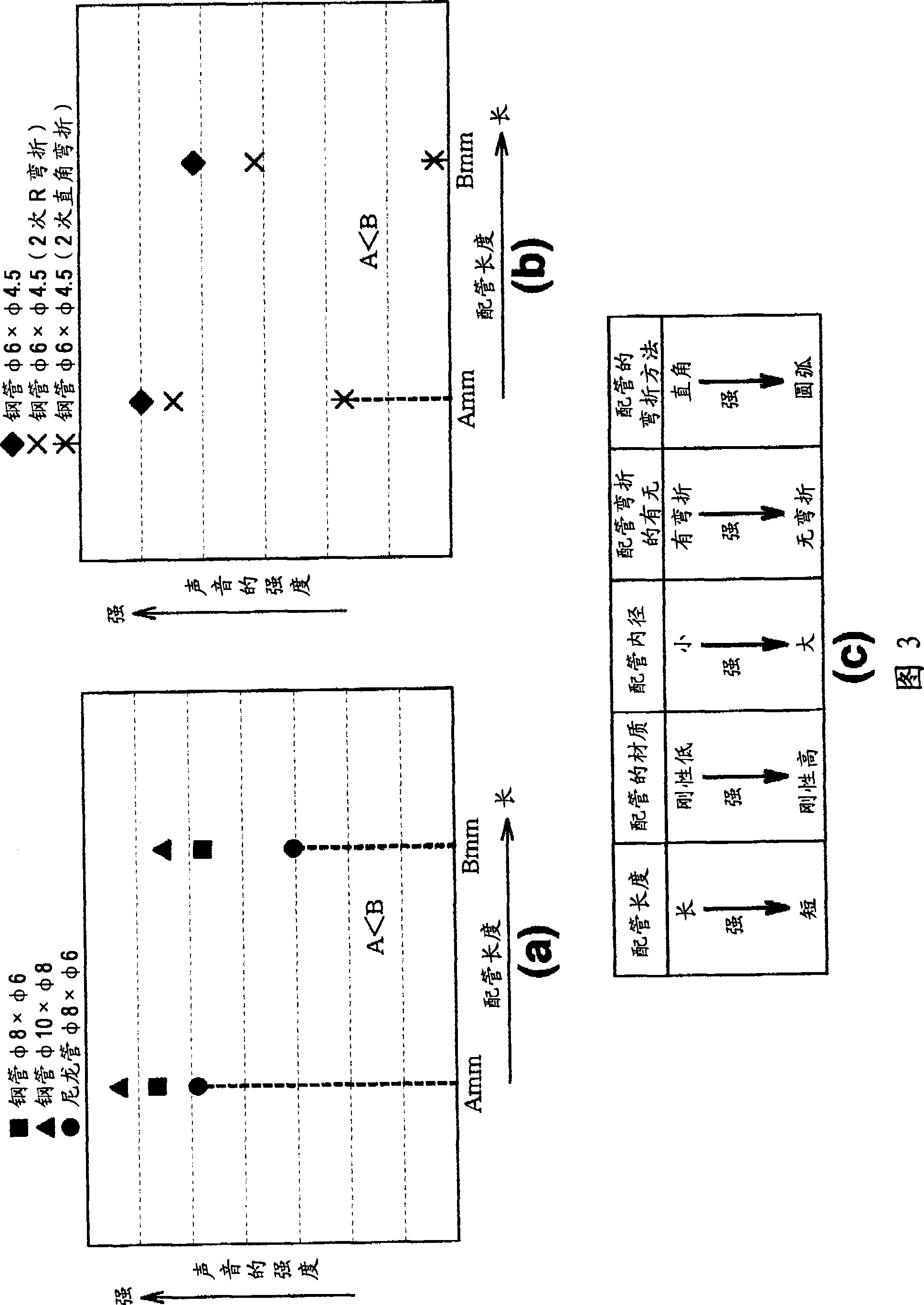

[0041] 1, the spindle device has a horizontal hollow shaft-shaped main shaft 11, a horizontal cylindrical sleeve 12 surrounding the main shaft 11, a first bearing 21 and a second bearing 22 on the left side of the main shaft 11 that are spaced apart in the axial direction. , the third bearing 23 supporting the right side of the main shaft 11, surrounding the first bearing 21 and the second bearing 22, and fixing the left housing 24 on the inner surface of the sleeve 12, surrounding the third bearing 23, and fixing on the inner surface of the sleeve 12 on the right side housing 25.

[0042] On the outer surface of the main shaft 11, there are provided a large-diameter portion 31, a middle-diameter portion 32, and a small-diameter portion 33 which are successively connected via steps from left to right.

[0043] A stator 35 of a motor 34 is fixed on the inner surface of the sleeve 12 between the second bearing 22 and the third bearing 23 . Corresponding to the stator 35 , a rot...

Embodiment approach 2

[0065] In Embodiment 2 shown in FIG. 6 , the three first to third detection sound propagation paths 71 to 73 gathered in Embodiment 1 are re-branched into three paths, and sensors are respectively installed on the branched paths. . In Embodiment 2, parts corresponding to those in Embodiment 1 are denoted by the same reference numerals in FIG. 6 , and description thereof will be omitted.

[0066] Three fourth to sixth pipes 101 to 103 are connected to the manifold pipe 74 . The fourth to sixth acoustic sensors 111 to 113 and the fourth to sixth opening and closing operation valves 121 to 123 are provided on the respective pipes 101 to 103 . The signals of the acoustic sensors 111 to 113 are amplified for each sensor by the signal amplifier 83 .

[0067] The frequencies detectable by the acoustic sensors 111 to 113 may be different for each sensor or may be the same. In addition, it is also possible to use a microphone in a wide range whose detectable frequency is several Hz ...

Embodiment approach 3

[0071] Next, Embodiment 3 will be described with reference to FIG. 7 .

[0072] In the third embodiment, a reference signal of a specific frequency is propagated to the bearings 21 to 23 shown in the first embodiment. In the third embodiment, as in the case of the second embodiment, the parts corresponding to those in the first embodiment are given the same reference numerals in FIG. 7 , and descriptions thereof are omitted.

[0073] A branch pipe 131 is arranged in parallel with the manifold pipe 74 . There is a reference signal generating device 132 on the branch pipe 131 .

[0074] The reference signal generator 132 is operated by the reference signal control device 133 . The reference signal is determined by the specifications of the acoustic sensor 75 . For example, in the case of an acoustic sensor whose detectable frequency is near a specific frequency of 20 kHz or higher, use a device that generates a reference signal of the frequency, or use a detectable frequency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com