Method for producing iron drop and structure thereof

A manufacturing method and technology of iron bars, applied in fishing accessories, fishing, applications, etc., can solve the problems of environmental protection, toxicity, lead price and high processing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

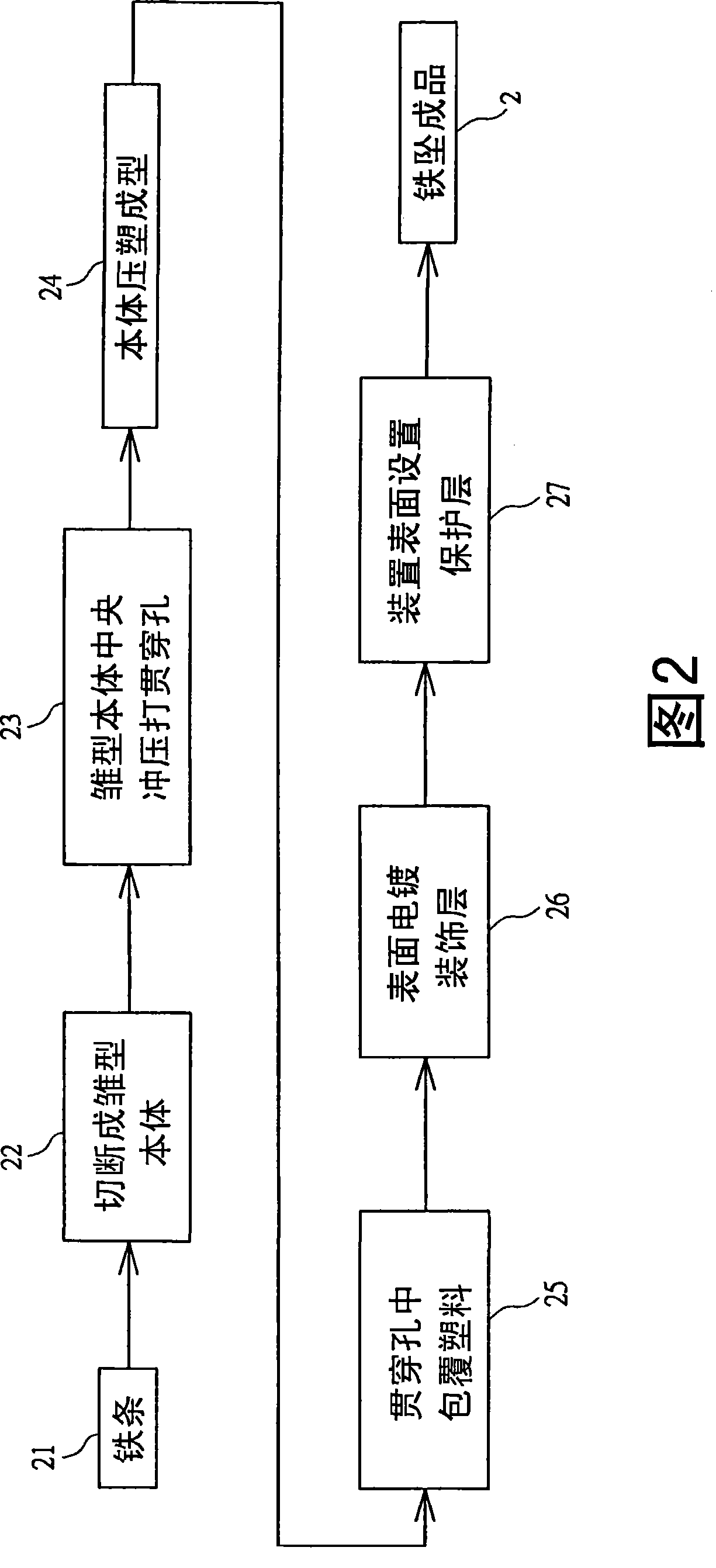

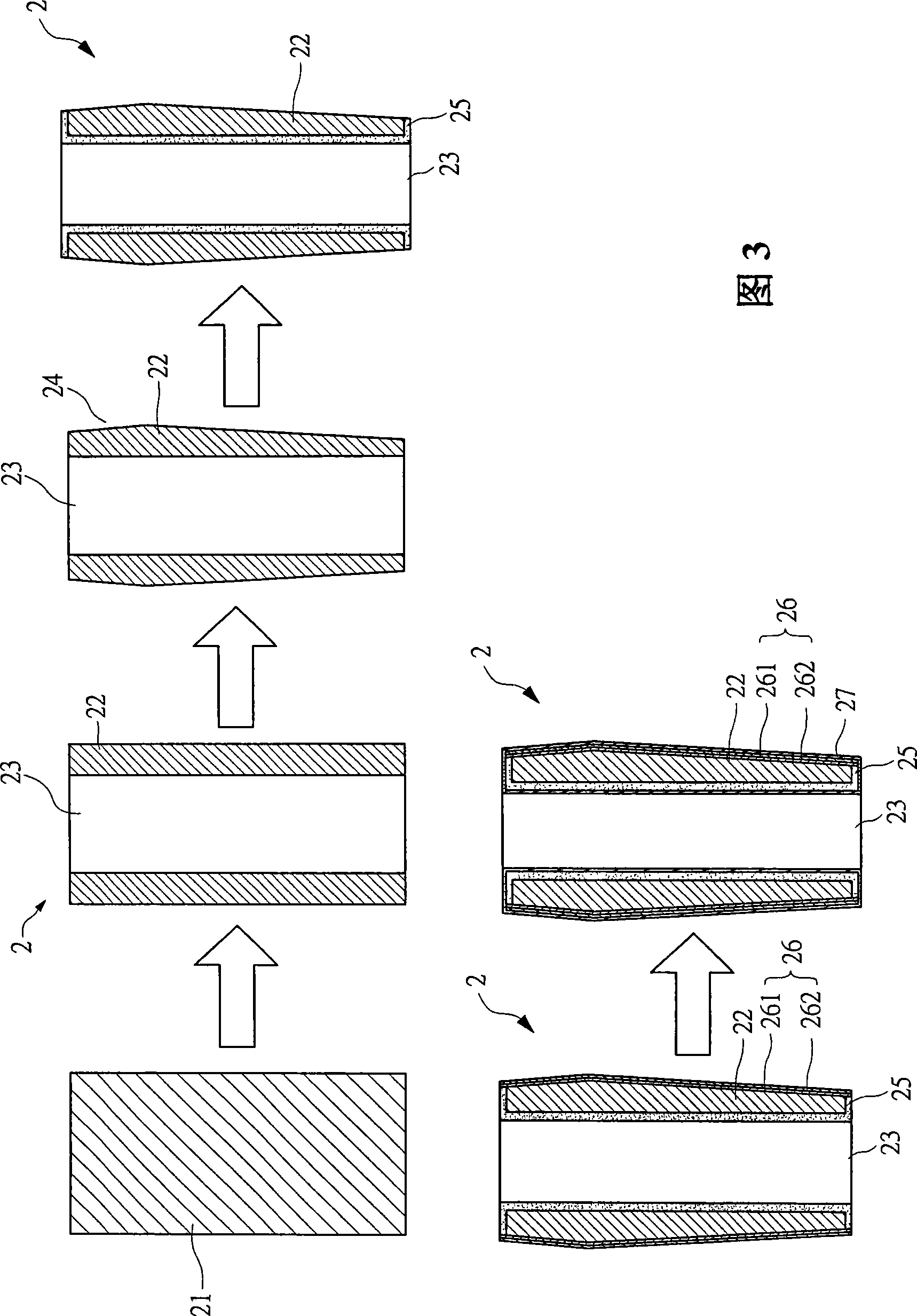

[0031] In order to make it easier to understand the manufacturing method and structure of the present invention, as well as the effects that the present invention can achieve, it is described as follows in conjunction with the drawings:

[0032] First of all, please refer to Figures 2 and 3, which are a flow chart and a schematic diagram of the manufacturing steps of the iron pendant 2 of the present invention,

[0033] Step 1: cutting the iron bar 21 into a prototype body 22 of appropriate length;

[0034] Step 2: Punch a through hole 23 in the center of the prototype body 22 by stamping;

[0035] Step 3: compression molding 24 of the prototype body 22;

[0036] Step 4: Coating a plastic 25 in the through hole 23 and the two ends of the body 22, the material of the plastic 25 can be PE;

[0037] Step five: set a decorative layer 26 on the surface of the prototype body 22, wherein the decorative layer 26 is a galvanized layer 261 and a baking varnish layer 262, and the bakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com