Micro-nano fibre with curled secondary structure, and preparation and use thereof

A technology of curling secondary structure and micro-nano fibers, applied in the field of micro-nano materials, can solve the problems of difficult processing operation, low strength, etc., and achieve the effect of controllable process and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

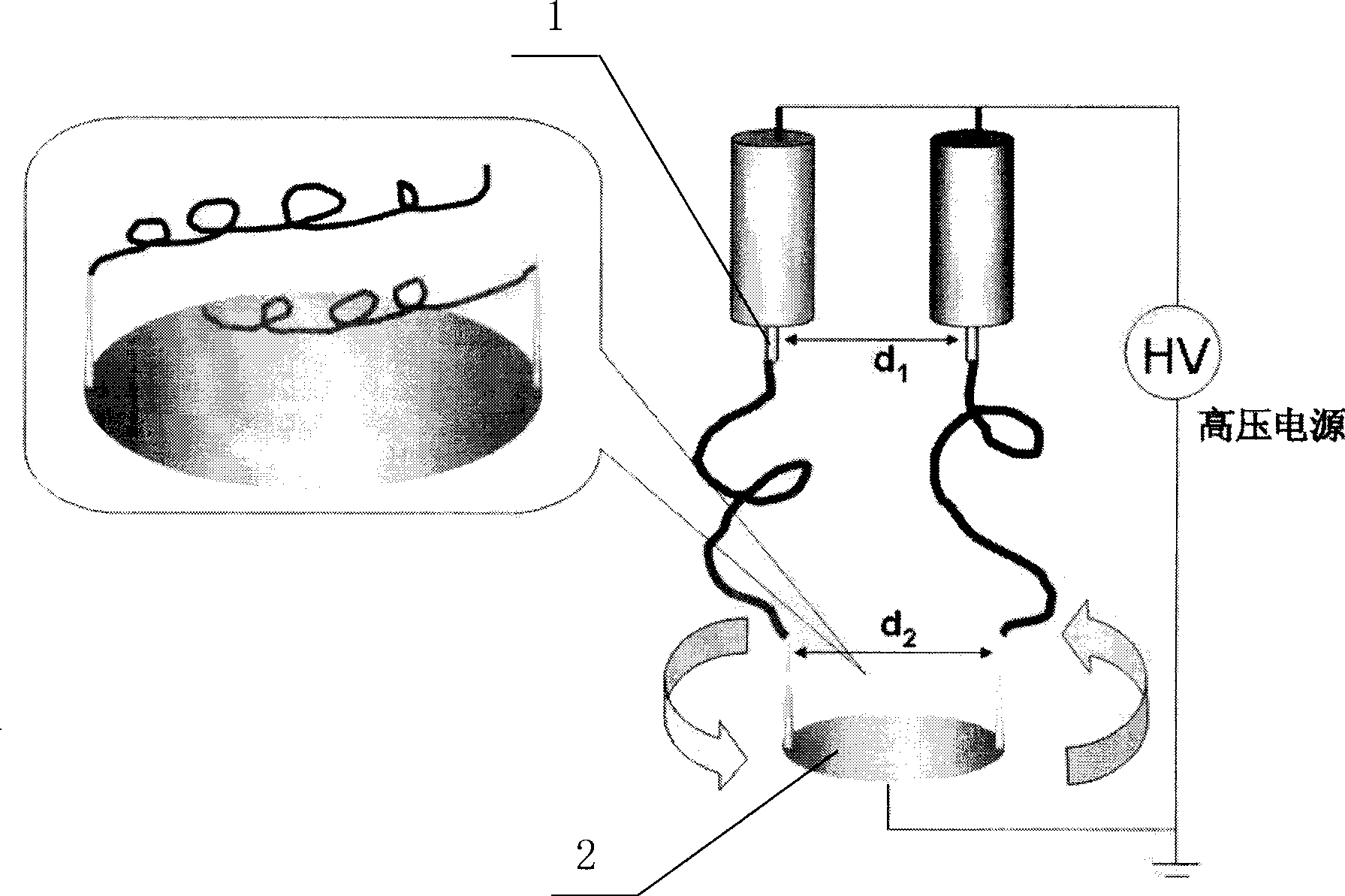

[0031] See figure 1 Composite electrospinning device. Two or more spinnerets 1 are fixed at the same height; there is a turntable receiver 2 under the spinneret; the spinneret and the turntable receiver are respectively connected to the positive and negative poles of the high voltage power supply.

[0032] The turntable receiver is composed of a turntable with two or more vertical needle electrodes fixed on its edge. The plane of the turntable receiver is perpendicular to the direction of the electric field, the needle electrode is perpendicular to the plane of the turntable and parallel to the electric field, and the turntable receiver is connected with a rotary motor with controllable speed.

[0033] Polymethyl methacrylate (PMMA) was dissolved in dimethylformamide (DMF) to prepare a 15% (mass percent) solution. Each take 1g of this solution and join respectively in the feeding device that is connected with 2 spinneret needles, follow as follows figure 1 The experimental ...

Embodiment 2

[0037] The composite electrospinning device is the same as in Example 1.

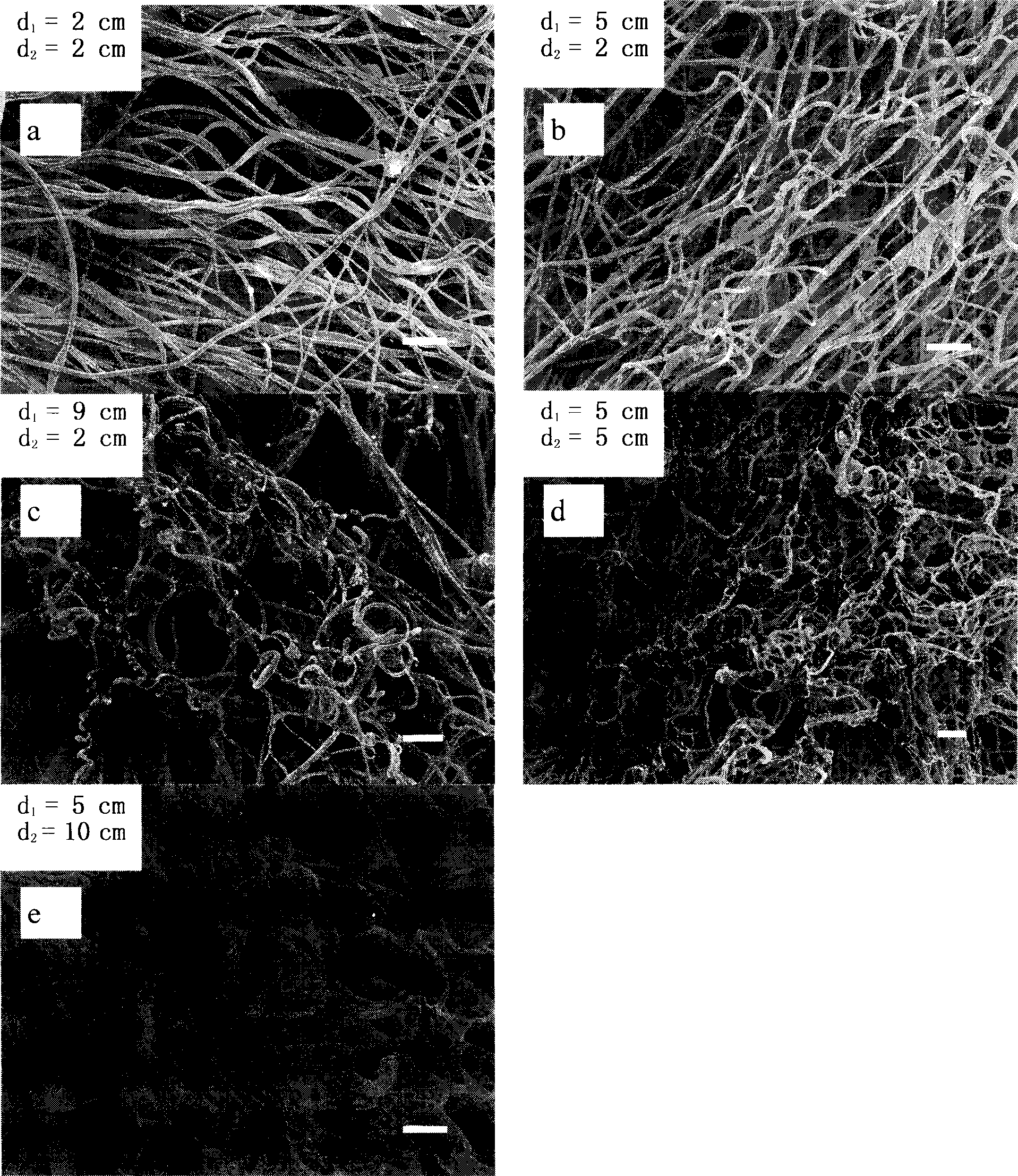

[0038] Polymethyl methacrylate (PMMA) was dissolved in dimethylformamide (DMF) to prepare a 15% (mass percent) solution. Each take 1g of this solution and join respectively in the feeding device that is connected with 2 spinneret needles, follow as follows figure 1 The experimental setup for spinning. The external environment temperature is 15°C, the relative humidity is 30%, the high-voltage power supply voltage is 14kV, the vertical distance between the spinning needle and the top of the needle electrode on the turntable receiver is 20cm, and the rotation speed of the turntable receiver is 2000-4000r / min. The spacing d between the needle electrodes on the fixed turntable receiver 2 2cm, adjust the distance d between the spinnerets 1 value. Collect the micro-nanofibers with coiled secondary structures on the needle electrodes on the spinner receiver.

[0039] Such as image 3 as shown, image 3 ...

Embodiment 3

[0042] The composite electrospinning device is the same as in Example 1.

[0043] Polymethyl methacrylate (PMMA) was dissolved in dimethylformamide (DMF) to prepare a 15% (mass percent) solution. Each take 1g of this solution and join respectively in the feeding device that is connected with 2 spinneret needles, follow as follows figure 1 The experimental setup for spinning. The external ambient temperature is 15°C, the relative humidity is 30%, the high-voltage power supply voltage is 14kV, the vertical distance between the spinning needle and the top of the needle electrode on the turntable receiver is 20cm, and the rotation speed of the turntable receiver is 2000-4000r / min. Fixed spacing d between spinnerets 1 5cm, adjust the distance d between the needle electrodes on the turntable receiver 2 value. Collect the micro-nanofibers with coiled secondary structures on the needle electrodes on the spinner receiver.

[0044] Such as image 3 as shown, image 3 b, 3d, 3e ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com