Loss return drop-out cross linked gel plugging process

A technology of cross-linking gel and gel, applied in wellbore/well components, sealing/isolation, earth-moving drilling, etc., can solve the problems of low leakage plugging success rate, insufficient compressive strength, limited strength growth, etc. , to achieve the effect of shortening the loss time of plugging, improving the overall structural strength, and reducing the downhole risk factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

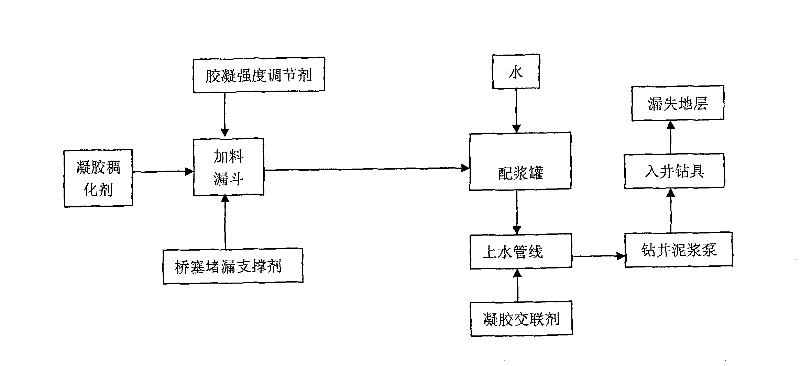

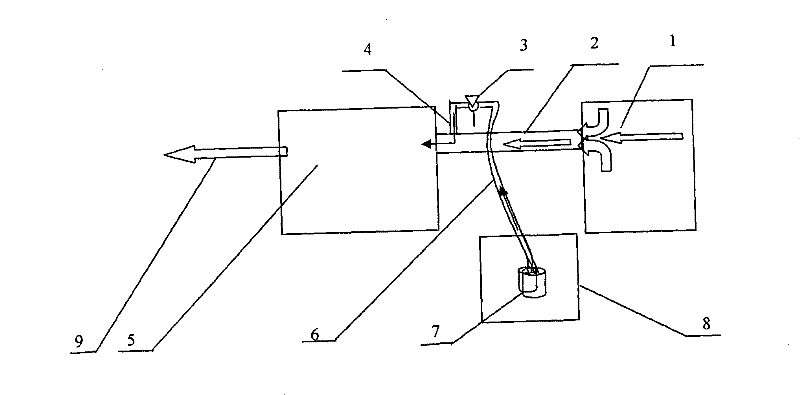

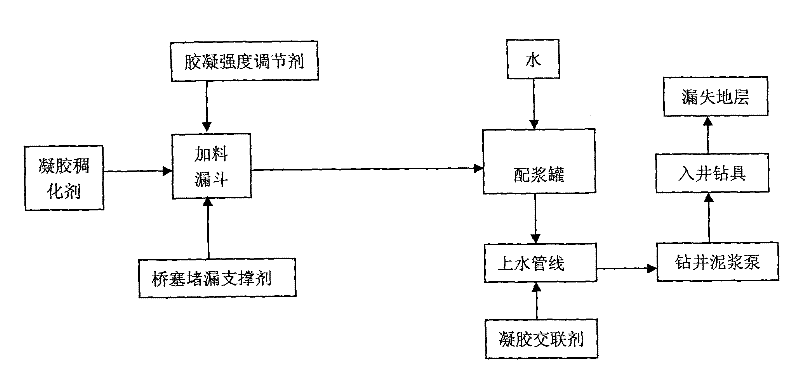

[0033] The invention discloses a loss-of-return cross-linked gel plugging process, in which a pre-cross-linked gel plugging slurry is prepared in a slurry mixing tank 1, and the pre-cross-linked gel plugging slurry is composed of water and a gel thickener , gel strength regulator and bridge plugging proppant, wherein the gel thickener accounts for 0.8-1% of the total weight, the gel strength regulator accounts for 3-4% of the total weight, and the bridge plugging proppant The agent accounts for 5-7% of the total weight, and the rest is water. After the components are fully dissolved and mixed, the light drill pipe is lowered to the bottom of the leakage layer for 5-10 meters, and the pre-crosslinked gel plugging slurry and gel crosslinked The agent is simultaneously injected into the leakage zone in the well, wherein the volume ratio of the pre-crosslinked gel plugging slurry and the gel crosslinking agent is 100:2.5-3.5. The mud mixing tank 1 is connected to the mud pump 5 th...

Embodiment 2

[0035] On the basis of Example 1, the mixing order of the components in the pre-crosslinked gel plugging slurry is as follows: first add 0.8 to 1% gel strength regulator in water, and after fully stirring, add 0.3 % gel thickener to properly increase the viscosity, then add 5-7% bridge plugging proppant, and finally add the remaining 0.5-0.7% gel thickener.

Embodiment 3

[0037]On the basis of Example 1 or 2, the simultaneous injection of the pre-crosslinked gel plugging slurry and the gel cross-linking agent specifically refers to: the pre-cross-linked gel plugging slurry and the gel cross-linking agent After the mud pump 5 is mixed evenly, it is synchronously injected into the leakage layer in the well. The suction line 2 of the mud pump is provided with a right-angle elbow 4 with a flow regulating valve. The pump 7 is connected, and the small electric pump 7 pumps the gel crosslinking agent into the mud pump 5, and the mud mixing tank 1 introduces the pre-crosslinked gel plugging slurry into the mud pump 5.

[0038] Example 3

[0039] As the best implementation mode of the present invention, on the basis of the above examples, before the gel cross-linking agent is mixed with the pre-cross-linked gel plugging slurry, first add water to dilute the gel cross-linking agent to The concentration of the original gel cross-linking agent is 40%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com