Real time information management method and system of high-frequency straight welded pipe production line

A straight seam welded pipe and real-time information technology, which is applied in the field of real-time information management methods and systems for high-frequency straight seam welded pipe production lines, can solve the problems of easy errors, inability to meet demands, and ancient ways of manually inputting information, and achieves easy-to-handle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

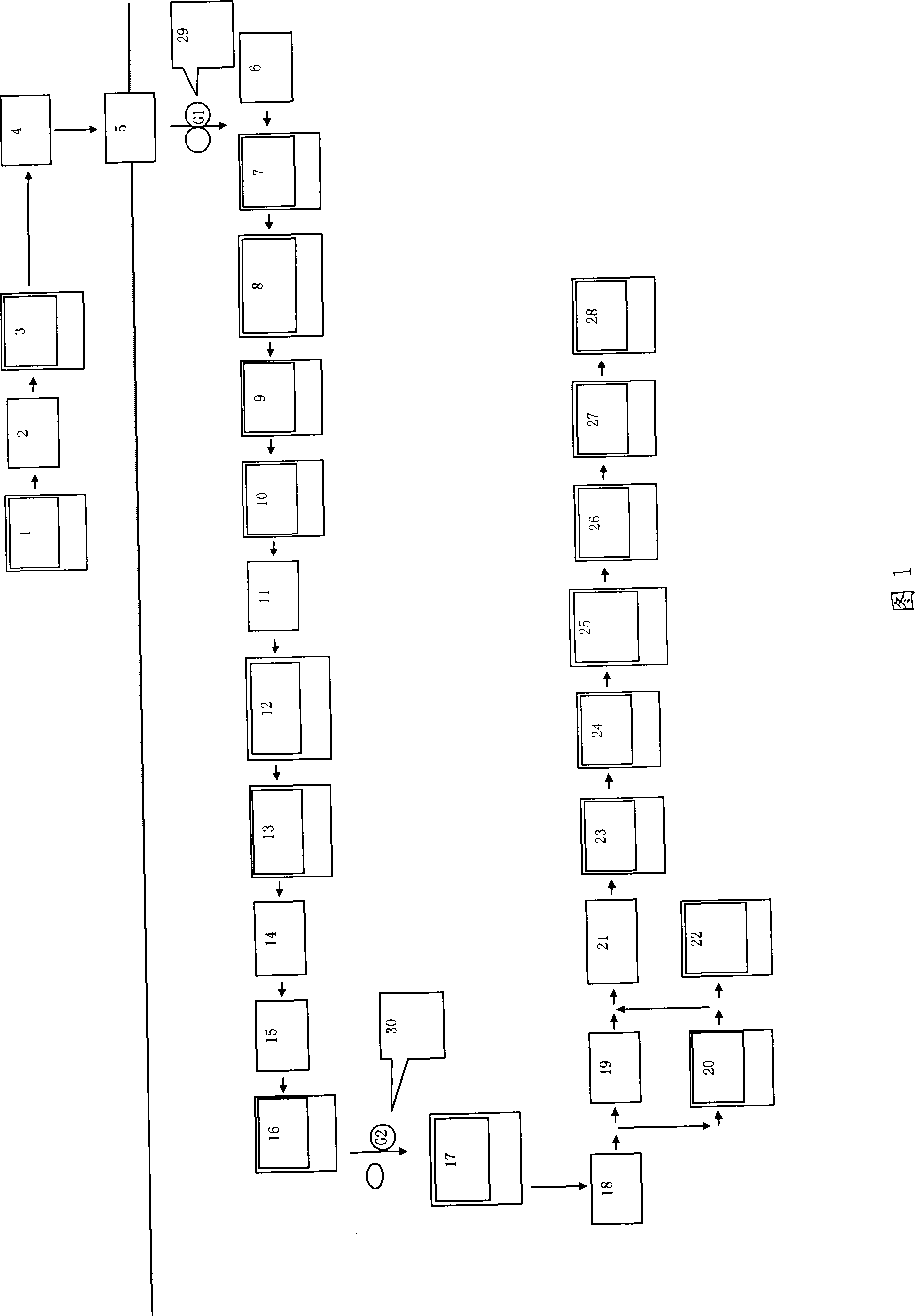

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the embodiments given by the accompanying drawings.

[0027] As shown in Figure 1, the real-time information management system of the high-frequency straight seam welded pipe production line of the present invention includes a PLC system, a steel pipe information master database, a first-in first-out roll-up database and a low-level basic database that are generated in sequence and enter the main machine line. It is characterized in that the steel pipe information master database includes raw material information about the raw plate coil 1, accurate strip steel length information, edge milling information about steel plate edge milling, steel plate defect information obtained through online ultrasonic flaw detection, information about cage forming Forming information, welding information about high-frequency welding, weld defect information obtained through o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com