End-face pump green light laser

A technology of end-pumping and lasers, which is applied to lasers, laser parts, phonon exciters, etc., can solve problems such as energy instability and poor beam quality, and achieve the effects of small overall size, stable power, and good beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

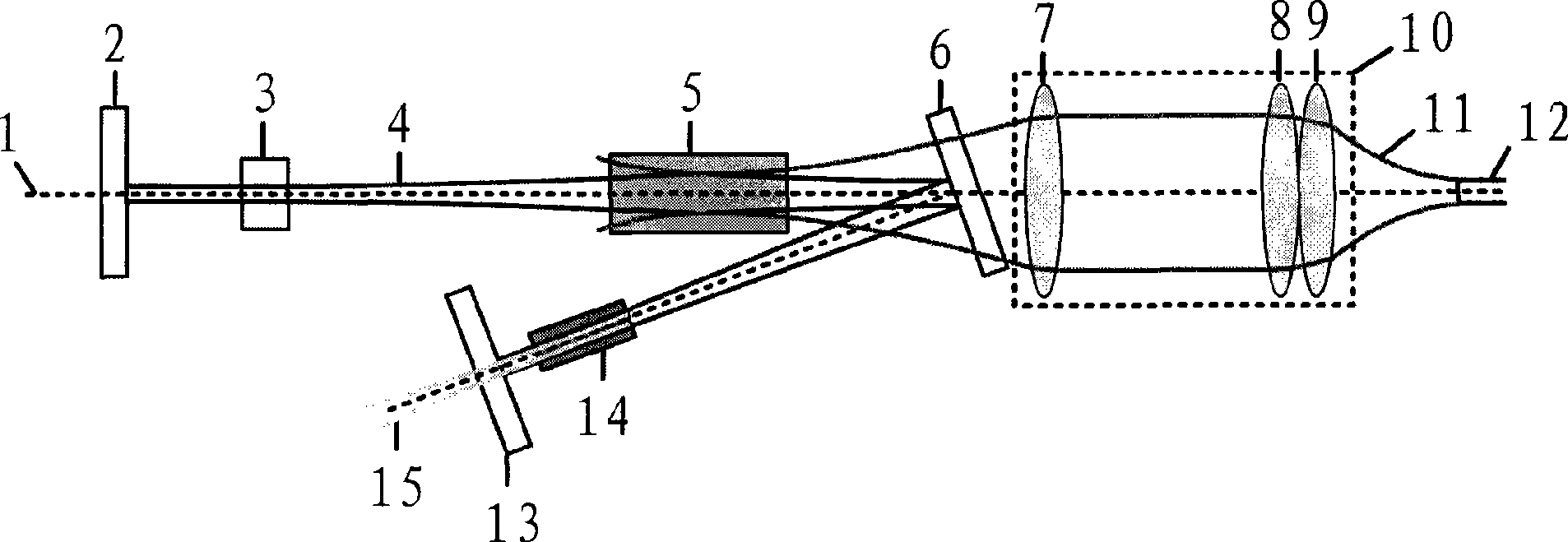

[0008] The present invention combines the attached figure 1 , its technical scheme is described in detail as follows: total reflection mirror 2, cavity mirror 6 and output mirror 13 constitute the laser resonant cavity; 7, 8, and 9 form a coupling focusing system 10; the pump light 11 is incident into the laser crystal 5 through the coupling focusing system 10 to generate the fundamental frequency light 4; the Q-switched crystal 3 is placed on the optical axis 1 to generate pulsed laser light; the fundamental frequency The light 4 oscillates in the resonant cavity, a nonlinear effect occurs in the frequency doubling crystal 14, and the frequency doubling produces a frequency doubling laser 15, which is output from the output mirror 13; it is pumped by an optical fiber 12; the pumping unit is composed of an optical fiber 12 and a coupling focusing mirror 10 , the pump light 11 is focused along the optical axis 1 through the coupling focusing mirror 10, and is incident on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com