Method for extracting xanthohumol from lupulus

A technology of xanthohumol and hops, which is applied in the field of xanthohumol and products containing the xanthohumol, can solve problems such as the lack of large-scale production, improve product yield and purity, simplify purification methods, and simplify processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 xanthohumol

[0034] 1 Pretreatment of hops: After the hops are crushed, pass through a 60-mesh (0.30mm) sieve, and take out a part to measure the water content.

[0035] 2.1 Preparation of hops raffinate: the pulverized hops samples were subjected to supercritical CO under the following conditions 2 Extraction: extraction pressure is 20Mpa, extraction temperature is 45°C, CO 2 The flow rate is 25L / h, and the extraction time is 3h. Collect the raffinate and store it in a 4°C refrigerator for later use.

[0036] 2.2 Separation and extraction of xanthohumol: Weigh 75g of hop extract sample, add 750ml of organic solvent (methanol / ethanol), ultrasonically extract for 5min at a temperature of 20°C and a power of 300W, and then filter to remove the solid residue. Collect the filtrate for later use.

[0037] 2.3 Purification of xanthohumol:

[0038] a) Concentrate the collected filtrate at low temperature to 50ml with a rotary evaporator, a...

Embodiment 2

[0041] Example 2 Detection and Identification of Xanthohumol

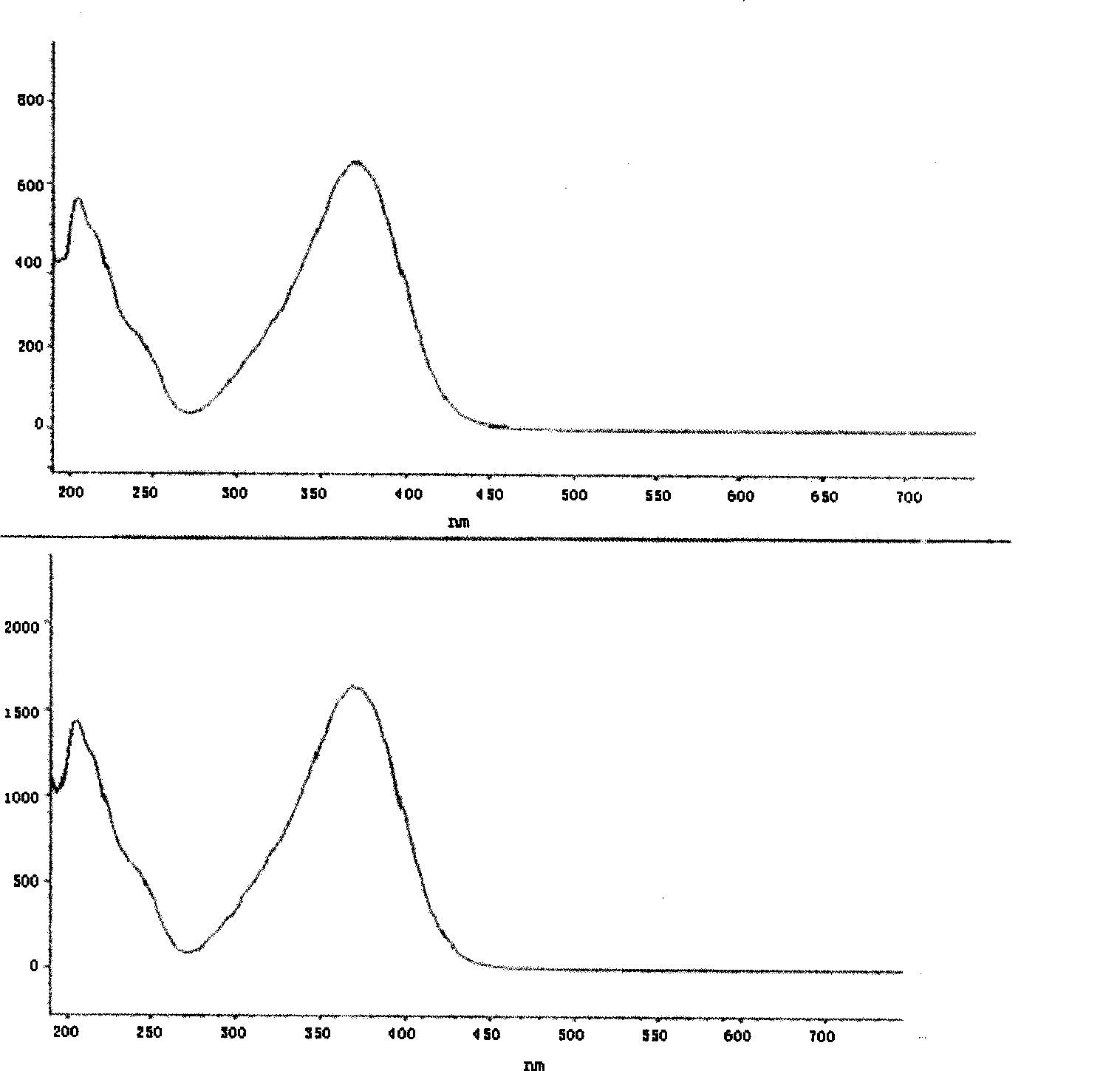

[0042] 1. Ultraviolet scanning: After properly diluting the purified xanthohumol sample, scan it within the wavelength range of 150-500.

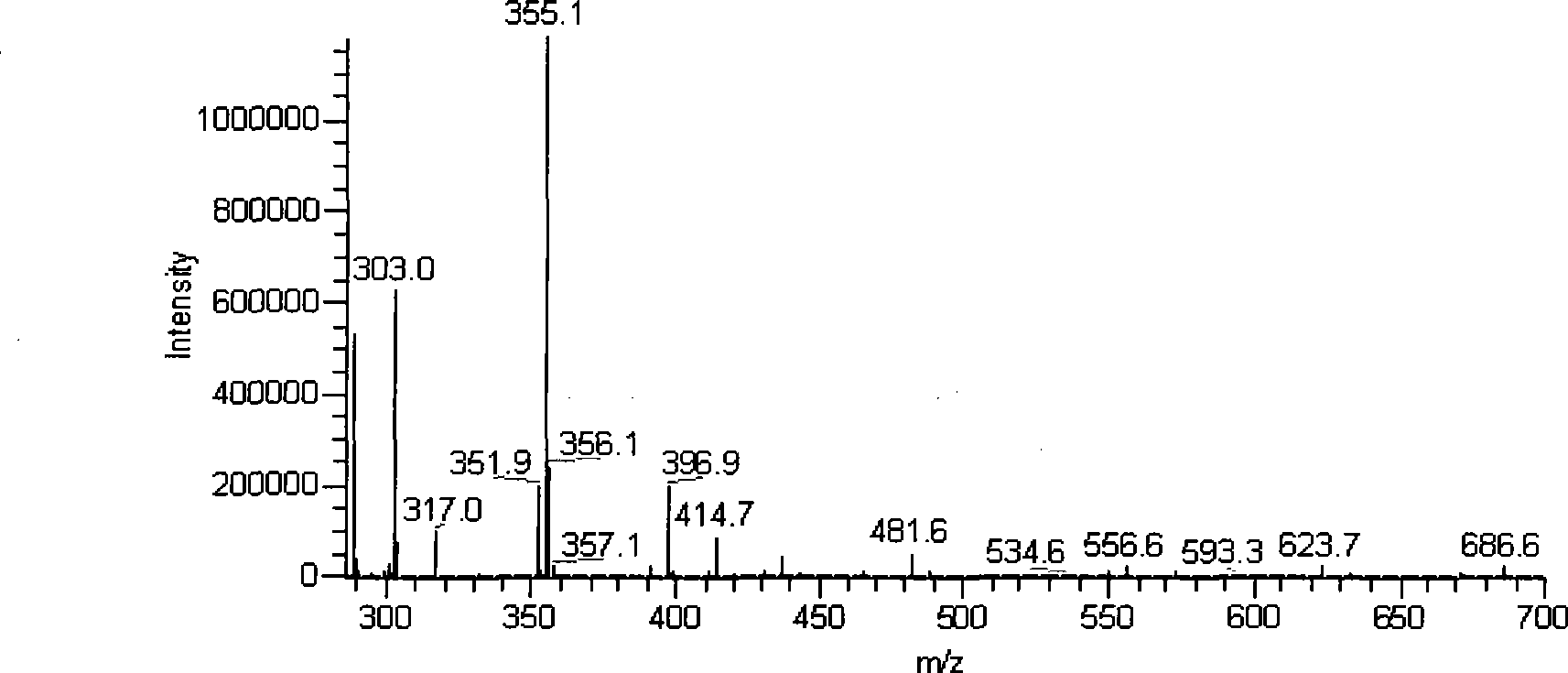

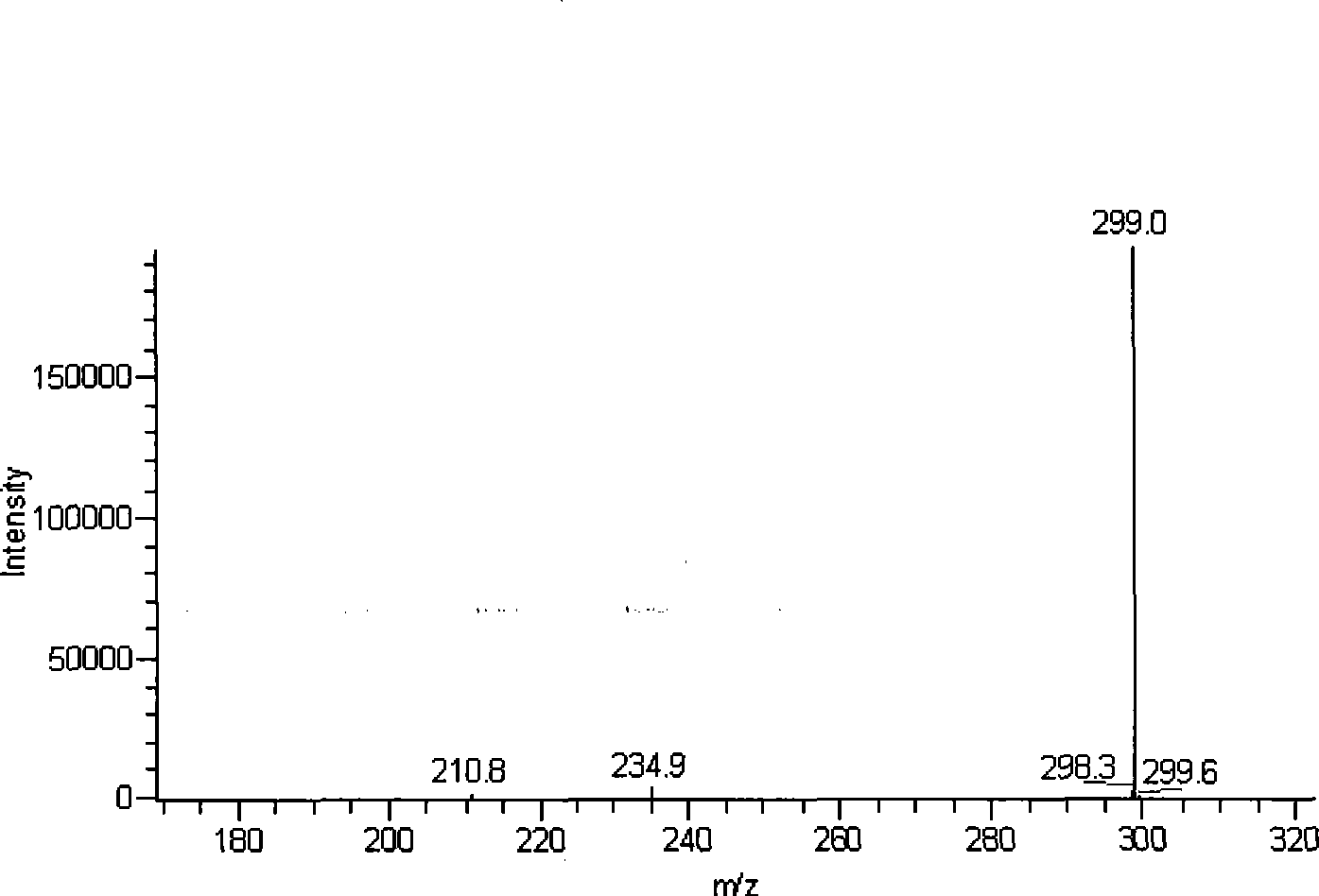

[0043] 2. LC-ESI-MS analysis and identification: Weigh a certain amount of purified xanthohumol sample, dissolve it in methanol solution according to a certain proportion, pass it through a 0.45um filter membrane, and wait for the test.

[0044] Liquid conditions: liquid chromatography: Agilent 1100; chromatographic column: Zorbax C18 (2.1×150mm, 5um); detector: DAD detector; wavelength: 370nm; column temperature: room temperature; flow rate: 0.2ml / min; injection volume : 30ul; mobile phase: methanol: water = 85:21

[0045] Mass Spectrometry Conditions:

[0046] Mass spectrometer: Thermoelectric Corporation (LCQ Deca XP);

[0047] Mass analysis instrument: ion trap;

[0048] Ion source: ESI;

[0049] Spray voltage: 4.5KV;

[0050] Capillary temperature: 300°C;

[0051] Sc...

Embodiment 3

[0063] Example 3 Determination of α-acid and β-acid

[0064] 1. Sample pretreatment

[0065] 1.1 Pretreatment of standard samples of hop extract: place standard samples of hop extract in a water bath at 25°C to 30°C, and stir well. Weigh 0.5g into a 50ml beaker, add 30ml methanol to dissolve, place in an ultrasonic water bath for 30min, transfer to a 100ml volumetric flask, dilute to volume with methanol, and mix well. Take 20ml in a 50ml volumetric flask, dilute to volume with methanol, and mix thoroughly. Filter with a 0.45um membrane, store in a sample bottle, and prepare for sample injection. Samples should be stored at low temperature and protected from light, so they are stable within 24 hours.

[0066] 1.2 Pretreatment of purified xanthohumol samples: Weigh 0.5g, add 30ml methanol to dissolve in a 50ml beaker, place in an ultrasonic water bath for 30min, transfer to a 100ml volumetric flask, dilute to volume with methanol, and mix well. Take 20ml in a 50ml volumetri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com