Luminous toughened glass basin and technique for producing the same

A technology of tempered glass and production process, which is applied in the process of producing decorative surface effects, glass molding, glass pressing, etc., which can solve the problems of unrealistic and technical level of washbasin making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The following will be described in detail in conjunction with the embodiments of the present invention.

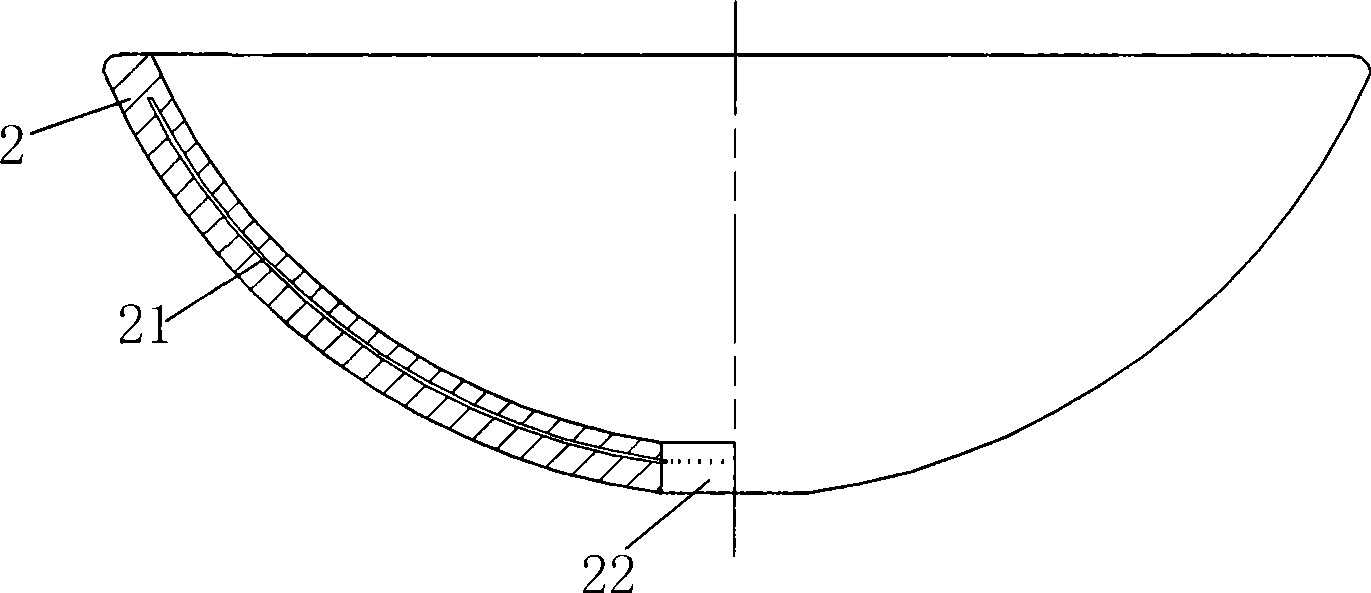

[0022] The production process steps of the light-emitting tempered glass washbasin of the present invention are as follows:

[0023] 1. Prepare the original glass piece

[0024] Prepare in advance the original sheet of flat glass that needs to be processed, depending on the shape of the bowl, usually round, so that the shape of the glass before and after forming can be basically kept the same. According to the needs of product design, the original plate glass can be square, or round, or elliptical, or polygonal, etc.

[0025] 2. Grooving and color printing

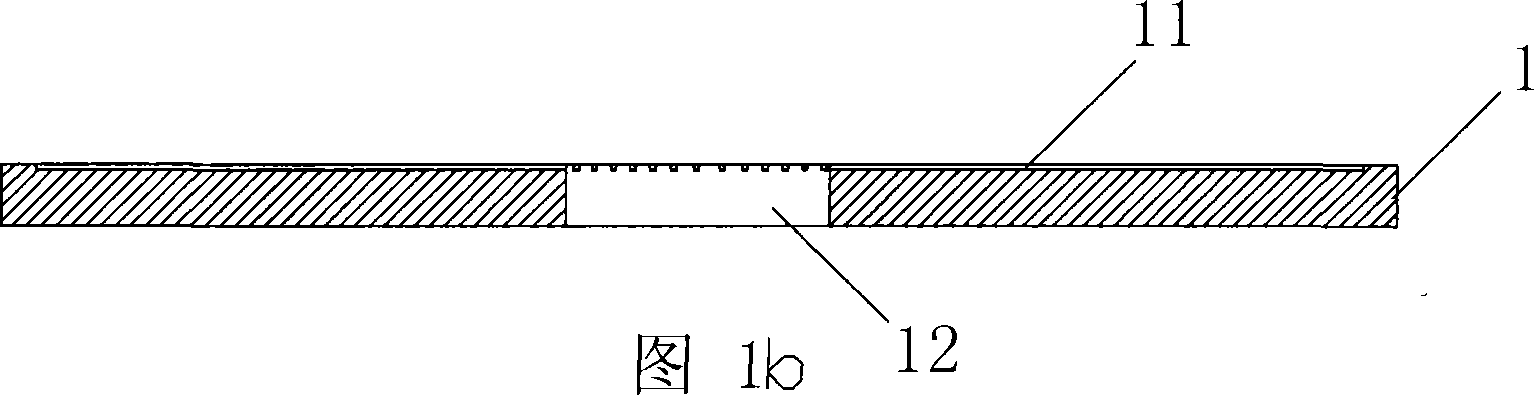

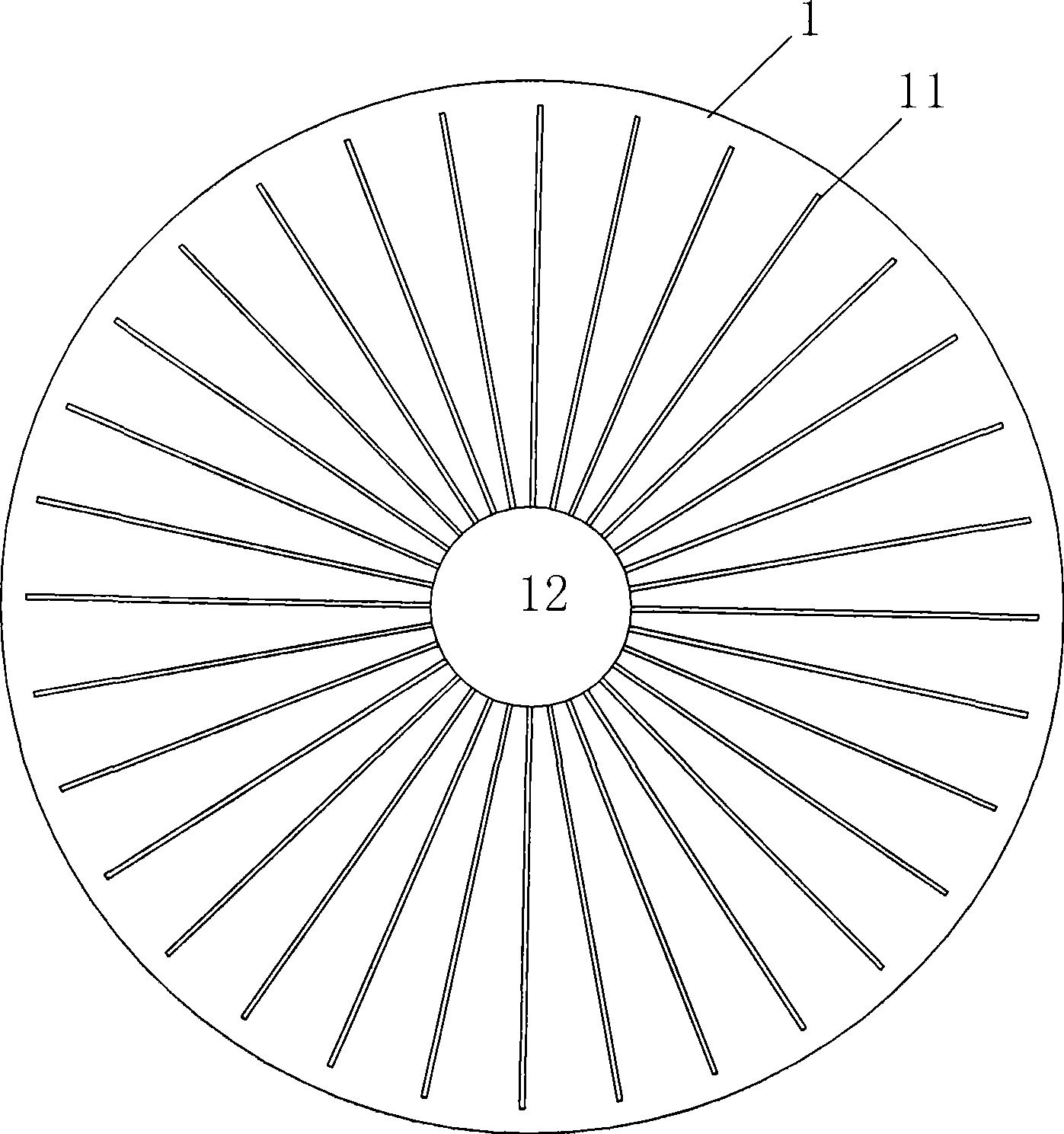

[0026] Carve a number of grooves according to the designed pattern on one or more pieces of formed flat glass, silk screen or paint on the surface of another flat glass, and then drill a mounting hole in the center of each flat glass ; The inner ends of all the grooves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com