Cooling unit and compressor

A refrigeration device and compressor technology, which is applied in the field of compressors, can solve the problems of reduced lubricating oil viscosity, reduced operating capacity, wear reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

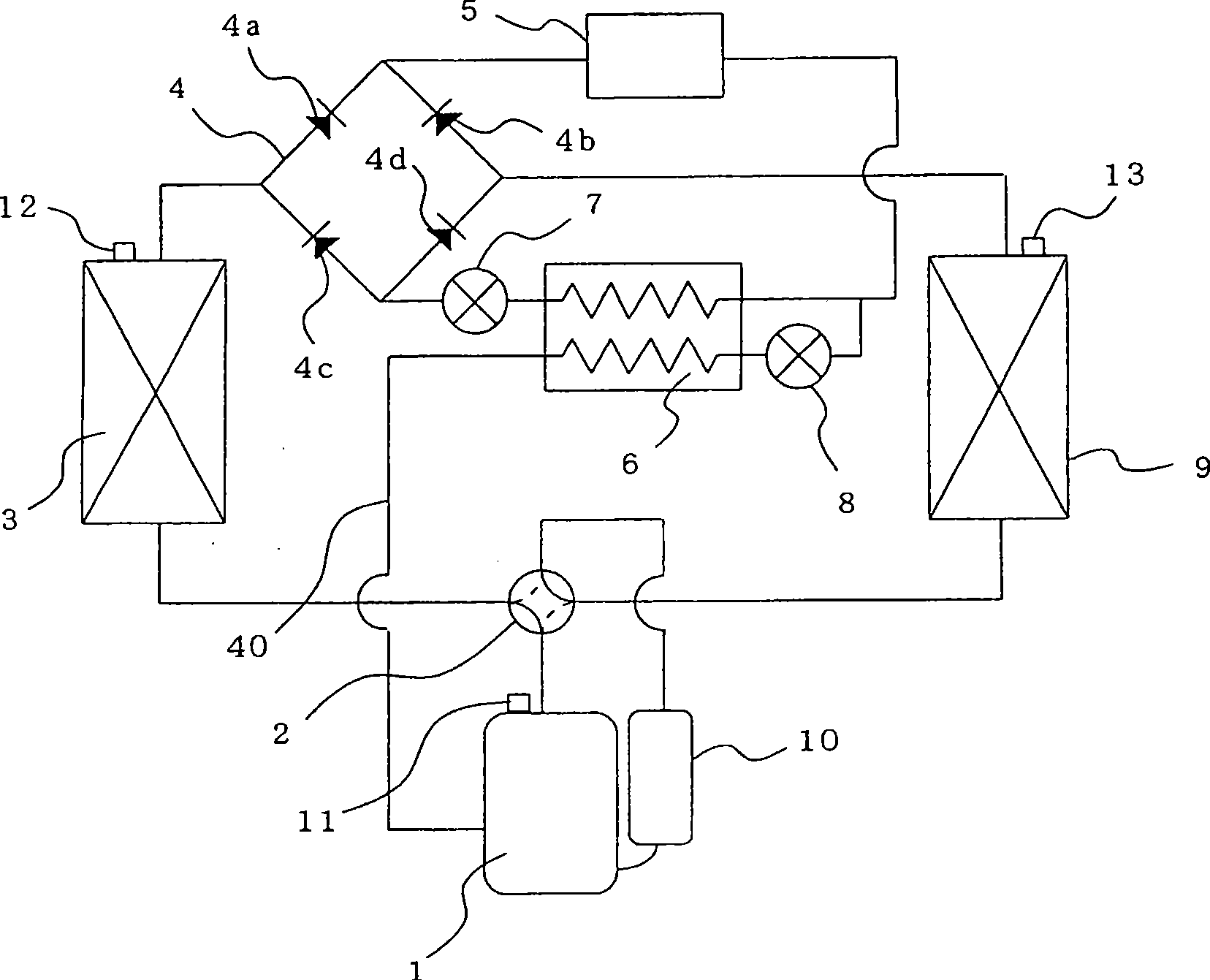

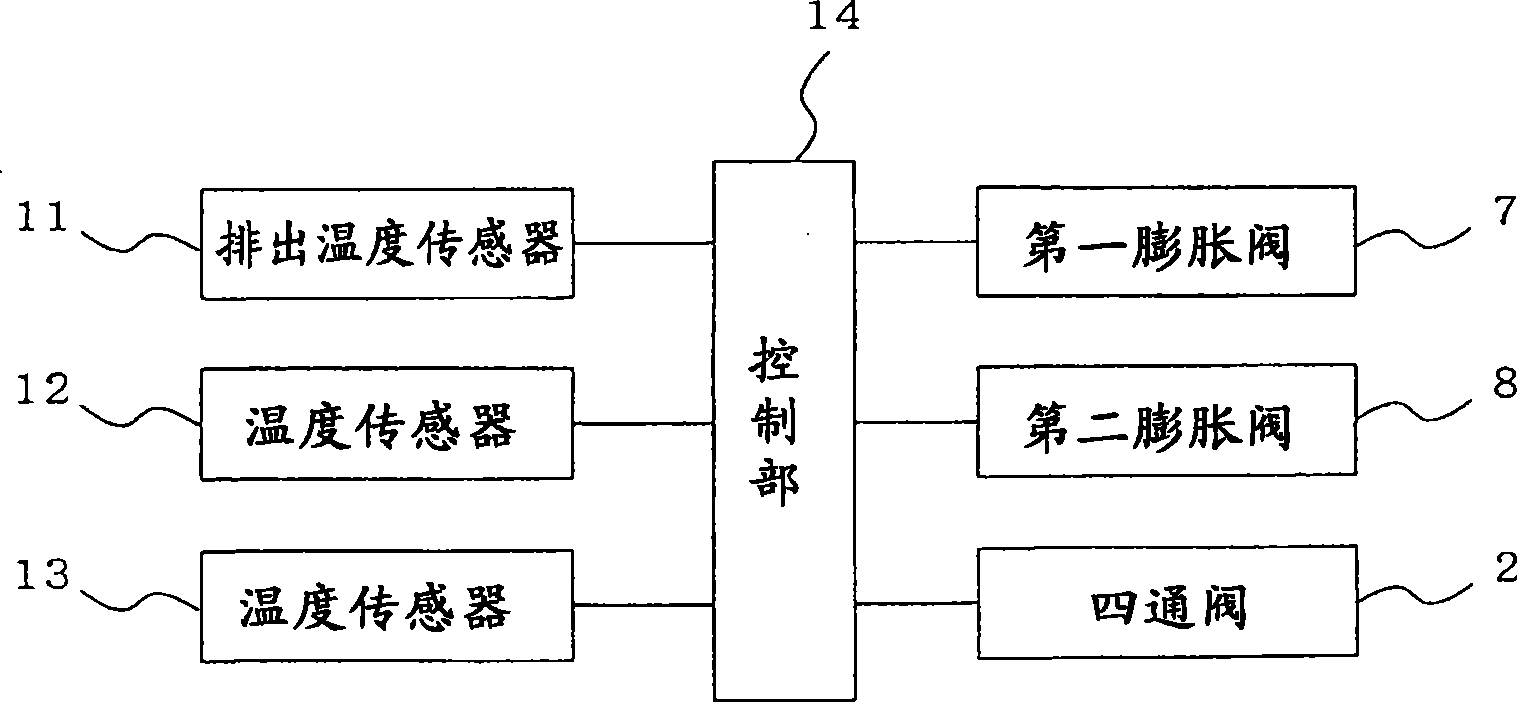

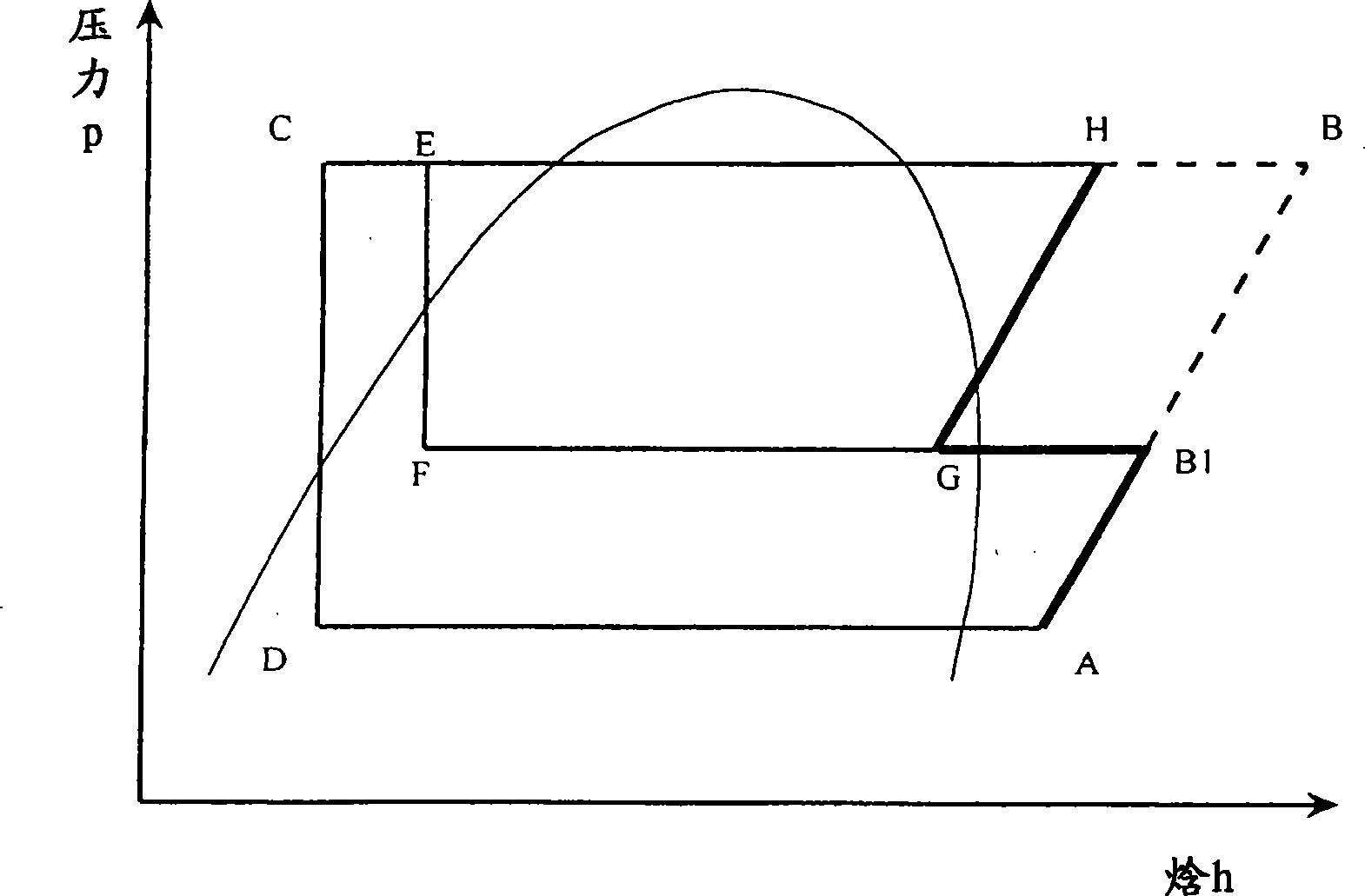

Method used

Image

Examples

Embodiment approach 2

[0052] In the above-mentioned first embodiment, although the timing of injecting the gas-liquid two-phase flash gas into the hermetic rotary refrigerant compressor 1 is not particularly described, in the second embodiment, effective injection timing and A specific structure of the hermetic rotary refrigerant compressor for injection at this timing will be described.

[0053] [33] First, a specific configuration of the hermetic rotary refrigerant compressor 1 will be described below.

[0054] Figure 4 and Figure 5 is to represent Embodiment 1 figure 1 The cross-sectional structure of the hermetic rotary refrigerant compressor 1 and the cross-sectional structure inside the compression chamber.

[0055] The hermetically sealed rotary refrigerant compressor 1 has, in a sealed container 20, an electric element unit 21 composed of a stator 21a and a rotor 21b, a compression element unit 23 driven by a rotating shaft (crankshaft) 38 integrally attached to the rotor 21b, Refrige...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap