Involute spline checkout chock gauge and manufacturing method thereof

A technology of involute splines and plug gauges, applied in the field of measuring tools, can solve the problems of waste, limited service life, irreparable, etc., and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

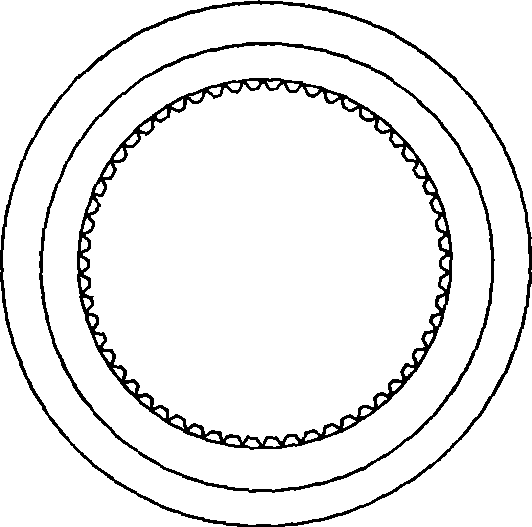

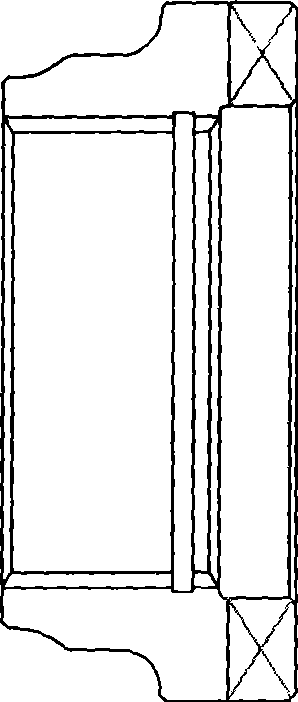

Image

Examples

Embodiment Construction

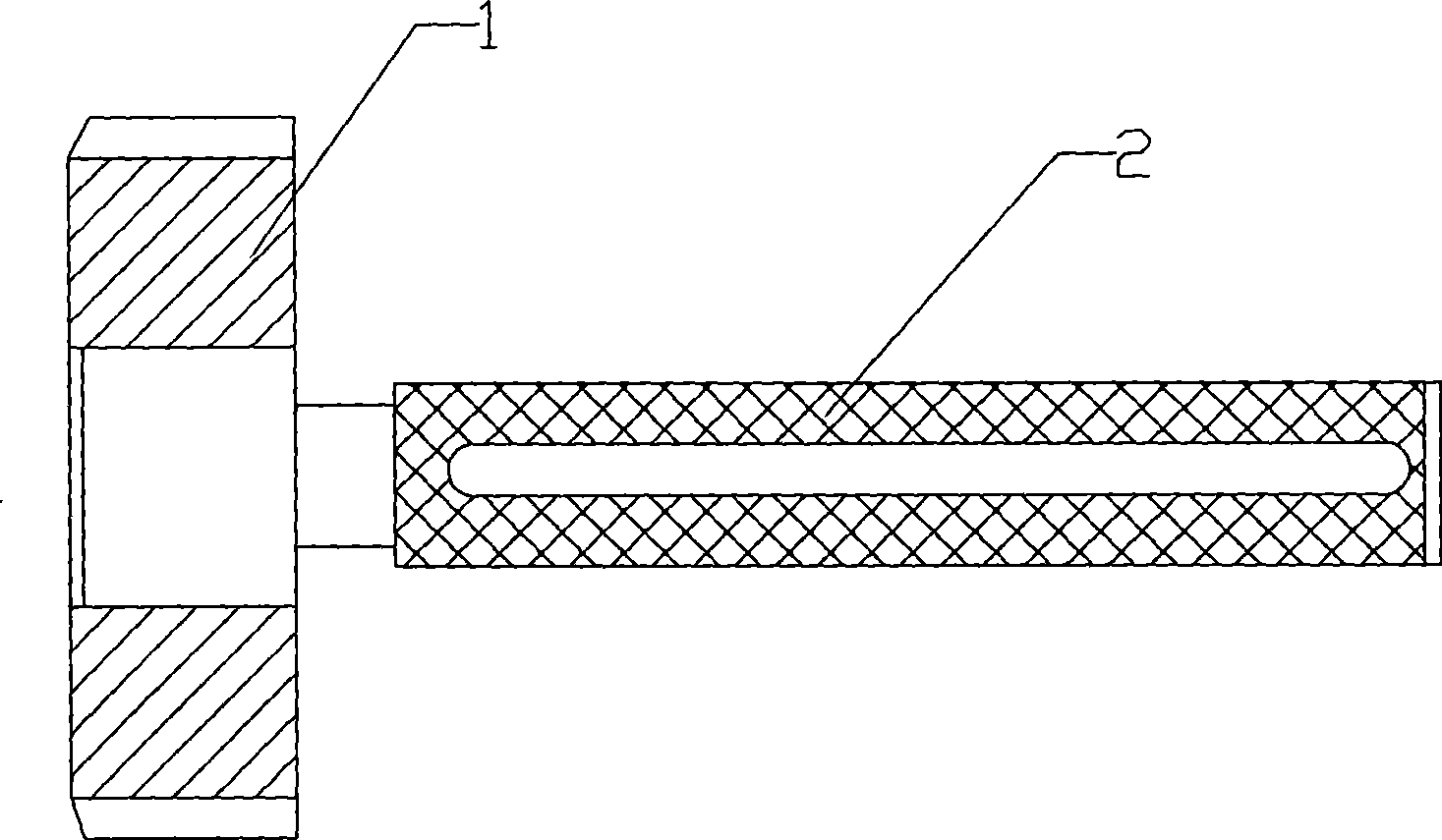

[0023] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0024] Such as image 3 As shown, the gauge body 1 of the involute spline inspection plug gauge of the present invention is made of scrapped high-speed steel hobbing cutters, and the gauge body 1 is covered with a titanium-coated hard film, and the titanium-coated hard film can be nitrogen Titanium hard film, titanium carbide hard film, titanium carbonitride hard film or titanium oxide hard film, titanium nitride hard film is used in this embodiment, and the thickness of the titanium-coated hard film is between 0.001-0.005.

[0025] The method for manufacturing the involute spline inspection plug gauge of the present invention comprises the following steps:

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com