Photomask, manufacturing method thereof, and pattern transfer print method

A mask pattern and manufacturing method technology, applied in the field of photomasks, can solve the problems of electrostatic damage, static electricity generated by shading patterns, and increased damage, and achieve the effect of suppressing electrostatic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings.

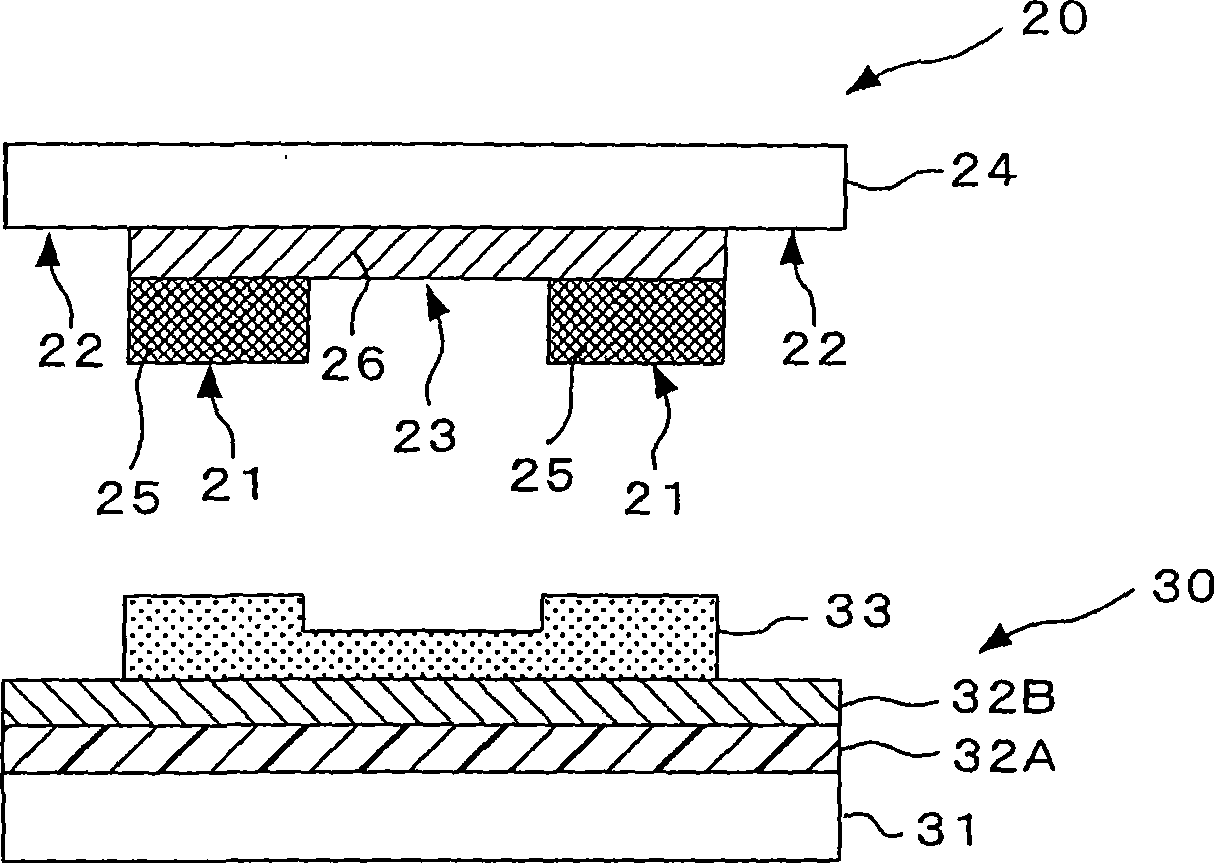

[0045] figure 1 It is a sectional view for explaining the pattern transfer method using the gray scale mask which is one embodiment of this invention. figure 1 The grayscale mask 20 shown is used to form a resist pattern 33 having a film thickness stepwise different on the transfer target body 30 . In addition, in figure 1 In , symbols 32A and 32B denote films laminated on the substrate 31 in the body to be transferred 30 .

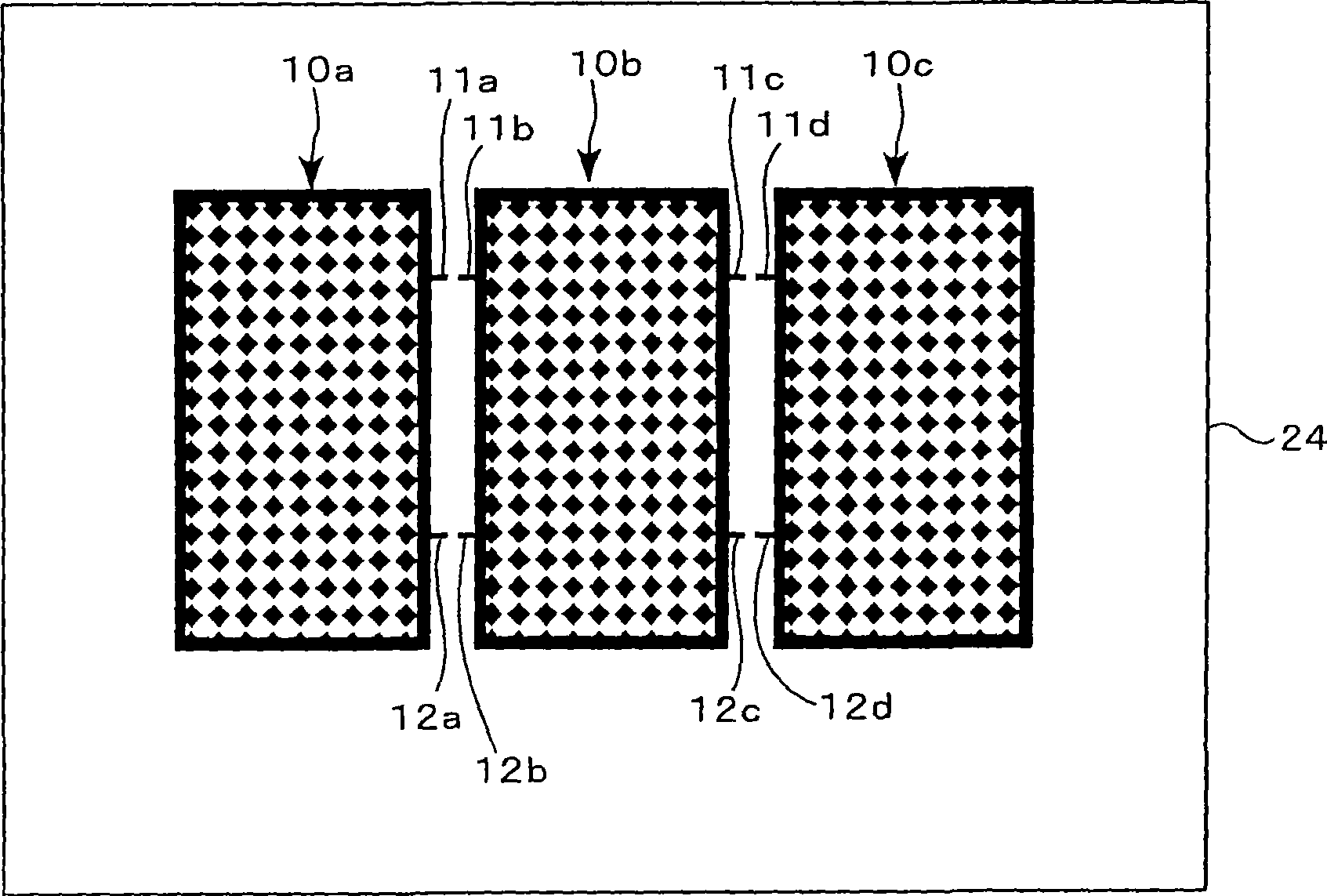

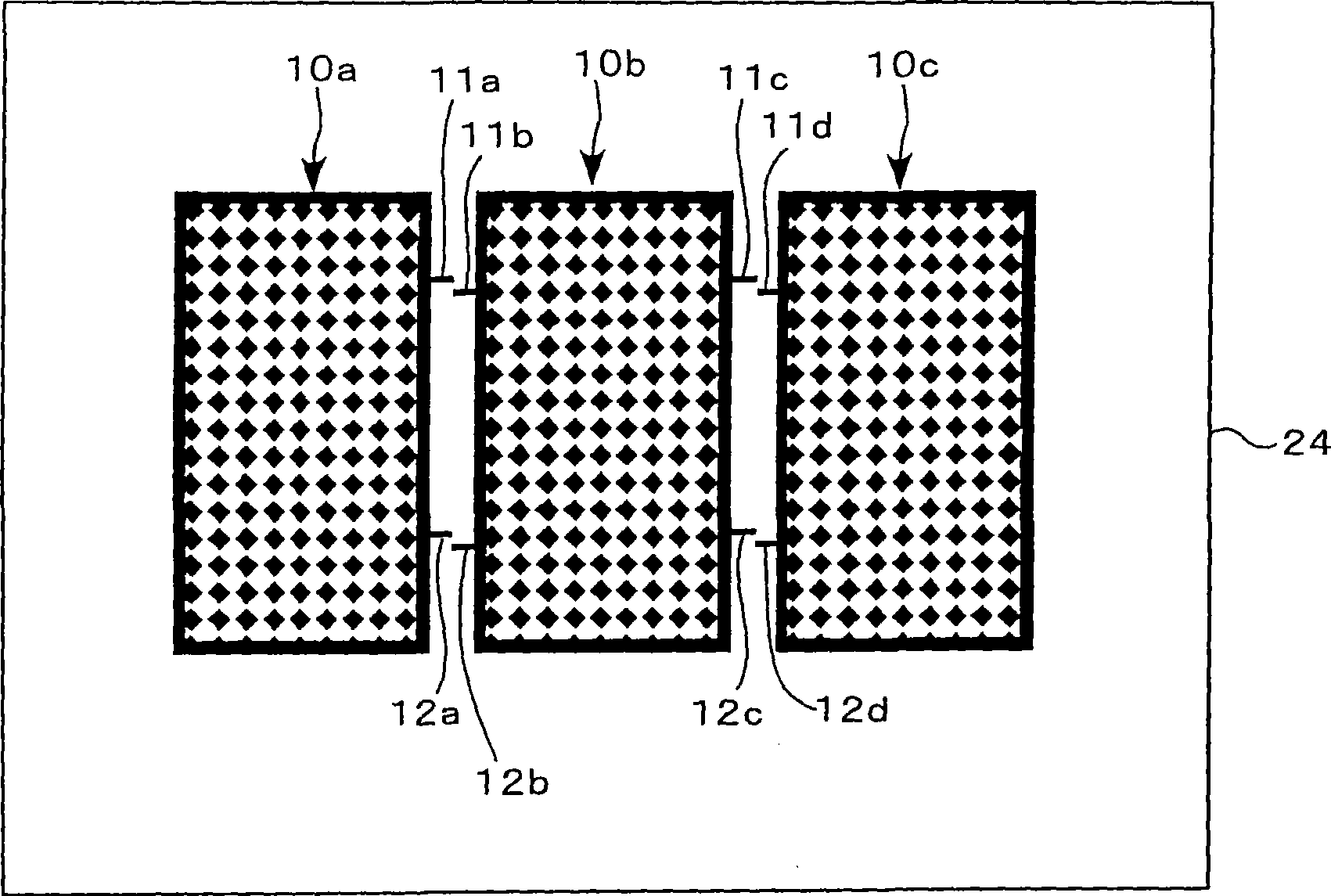

[0046] figure 1 The grayscale mask 20 shown has a mask pattern on a transparent substrate 24, and the mask pattern is formed by a light shielding portion 21 that shields exposure light (the transmittance is about 0%) when the grayscale mask 20 is used. , the translucent part 22 through which the exposure light exposed on the surface of the transparent substrate 24 passes, and the translucent part which reduces the transmitta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com