Data processing method and device of sintering control parameter

A data processing device and a technology for controlling parameters, applied in the field of iron and steel smelting, can solve the problems of acquisition errors, mutation of control models, acquisition failures, etc., and achieve the effects of improving quality and output, improving accuracy, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

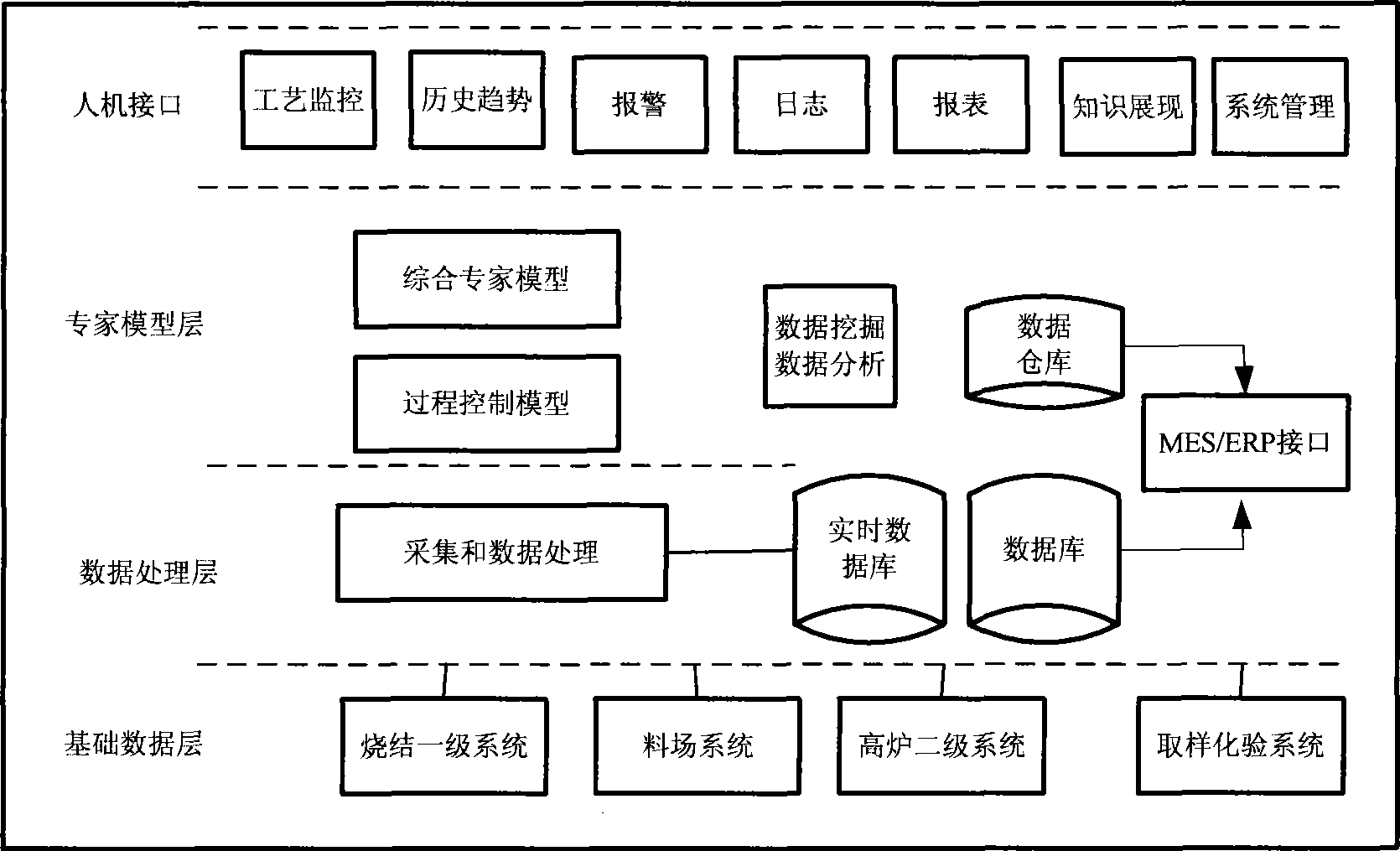

[0045] refer to figure 1 , is the structural diagram of the sintering process control system of the present invention.

[0046] see figure 1 As shown, the entire sintering production process can be divided into four levels, starting from the bottom layer: basic data layer, data processing layer, expert model layer and human-machine interface.

[0047] The basic data layer generates real-time production data of various control parameters in the sintering process through various data acquisition devices and testing instruments installed in the sintering primary system, material layer system, blast furnace secondary system, and sampling and testing system.

[0048] The production control parameters in the sintering process only nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com