Coaxial connector type fixed attenuator

A technology of coaxial connectors and fixed attenuators, applied in impedance networks, electrical components, multi-terminal pair networks, etc., can solve the problems of low frequency characteristics, high cost, and high manufacturing process requirements, and achieve low manufacturing costs and low reflection coefficients. Small, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

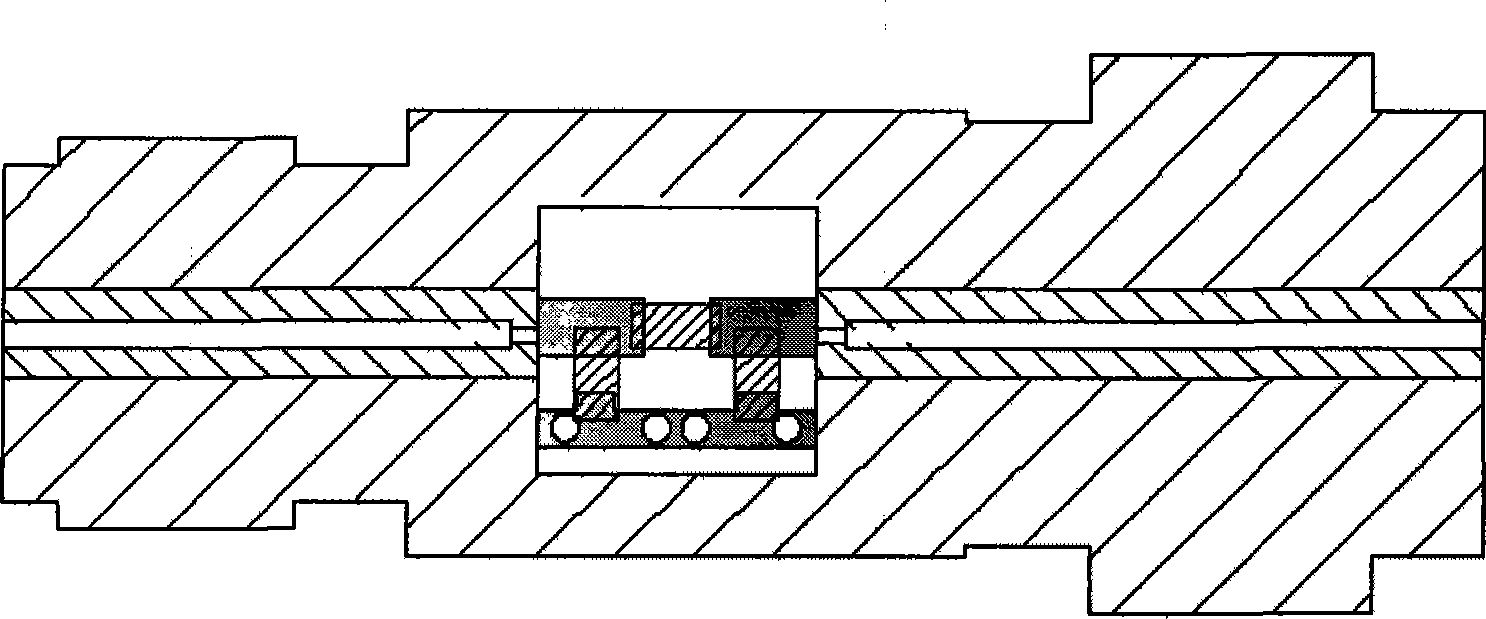

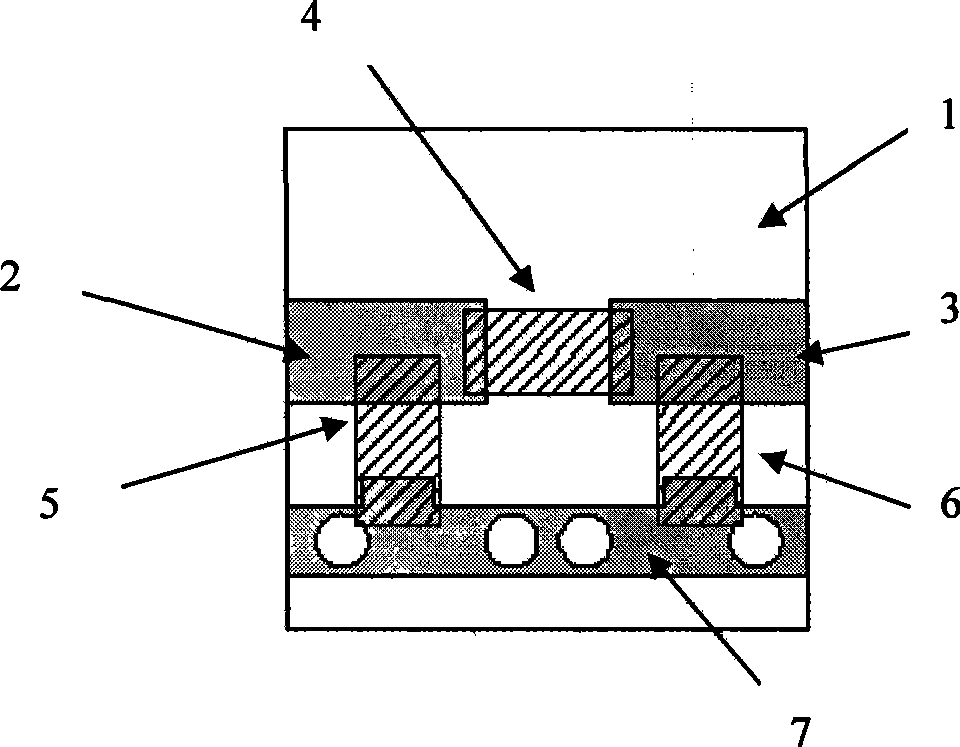

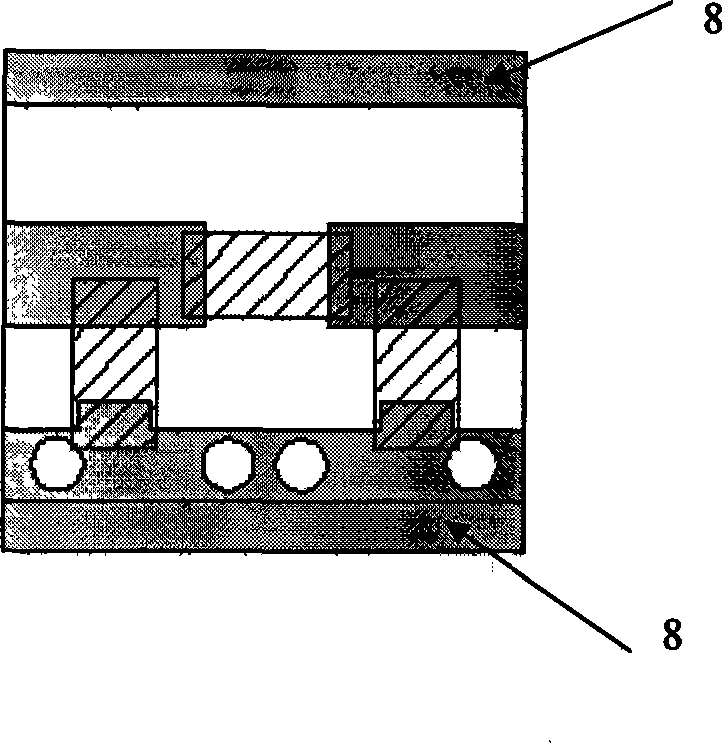

[0022] see figure 1 , which is a structural schematic diagram of the first embodiment of the coaxial connector type fixed attenuator of the present invention. It can be mainly broken down into Figure 1a , Figure 1b , Figure 1c and Figure 1d . see Figure 1a , which is a schematic diagram of three discrete chip resistors 4, 5, and 6 installed on the base 1 of the coaxial connector type fixed attenuator to form a π-type network. The π-type network is a two-way symmetrical broadband network. In the π-type network, the resistor 4 connecting the signal input and output terminals is generally called a series resistor, and the resistor 5 connecting the signal input terminal 2 and the common ground terminal 7 is connected to the signal output terminal 3. The resistor 6 and the common ground terminal 7 are collectively referred to as a parallel resistor. In a radio frequency circuit, the π-type network can also be called a π-type attenuator. In this embodiment, the signal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com