Alcohol fermentation waste liquid heat pump concentration process and device therefor

A technology of alcohol fermentation and bad liquid, which is applied in the direction of steam pressure evaporation, heating water/sewage treatment, food industry wastewater treatment, etc. It can solve the problems of maintaining the vacuum degree of the system and large energy consumption, and achieve the reduction of total water volume and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

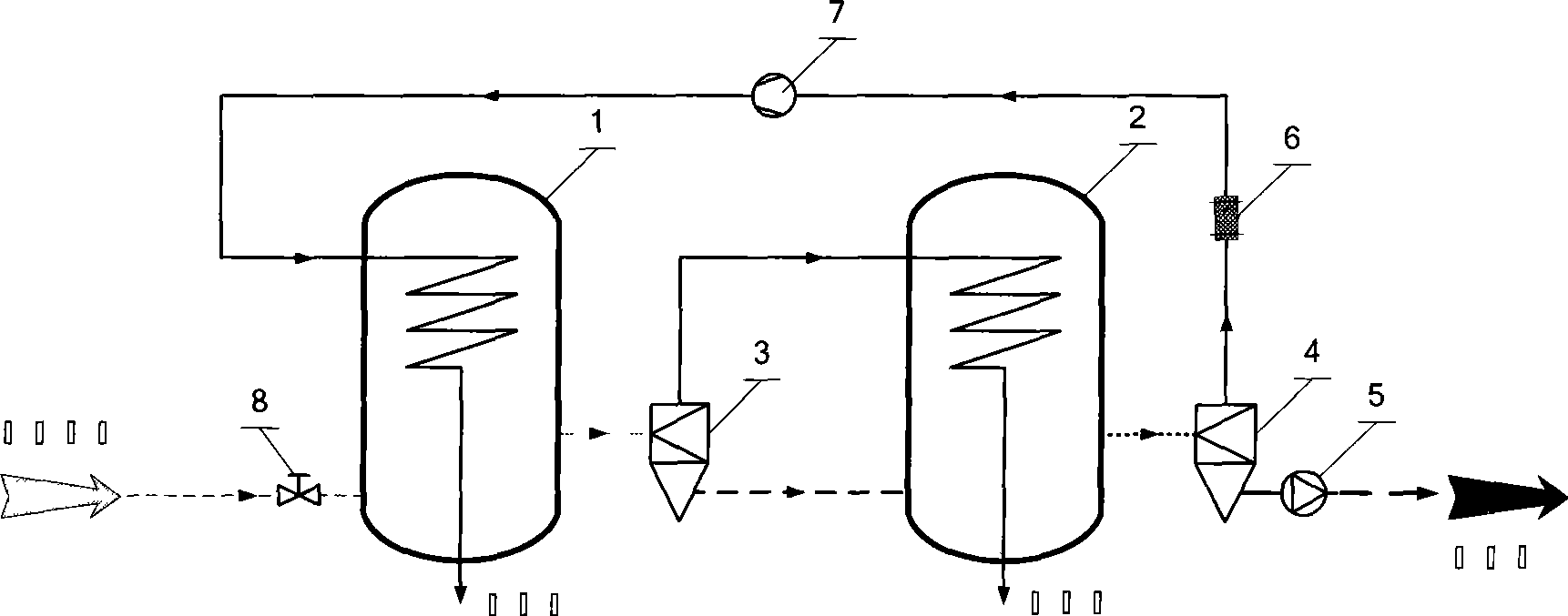

[0023] figure 1 It is the downstream feeding type alcohol fermentation lees heat pump concentration device and process diagram of the present invention, the overall flow direction of the lees is consistent with the flow direction of the heating steam, that is, the lees with low concentration and temperature first pass through the high-pressure evaporator 1, and then pass through The low-pressure evaporator 2, while the high-temperature heating steam heats the high-pressure evaporator 1, and the low-temperature heating steam heats the low-pressure evaporator 2. Such as figure 1 As shown, the bad liquid delivery pipeline is connected to the inlet port of the inlet pressure regulating valve 8, the outlet port of the inlet pressure regulating valve 8 is connected to the lower feed liquid inlet port of the high-pressure evaporator 1 through a pipeline, and the upper feed liquid outlet port of the high-pressure evaporator 1 passes through The pipeline is connected to the inlet end ...

Embodiment 2

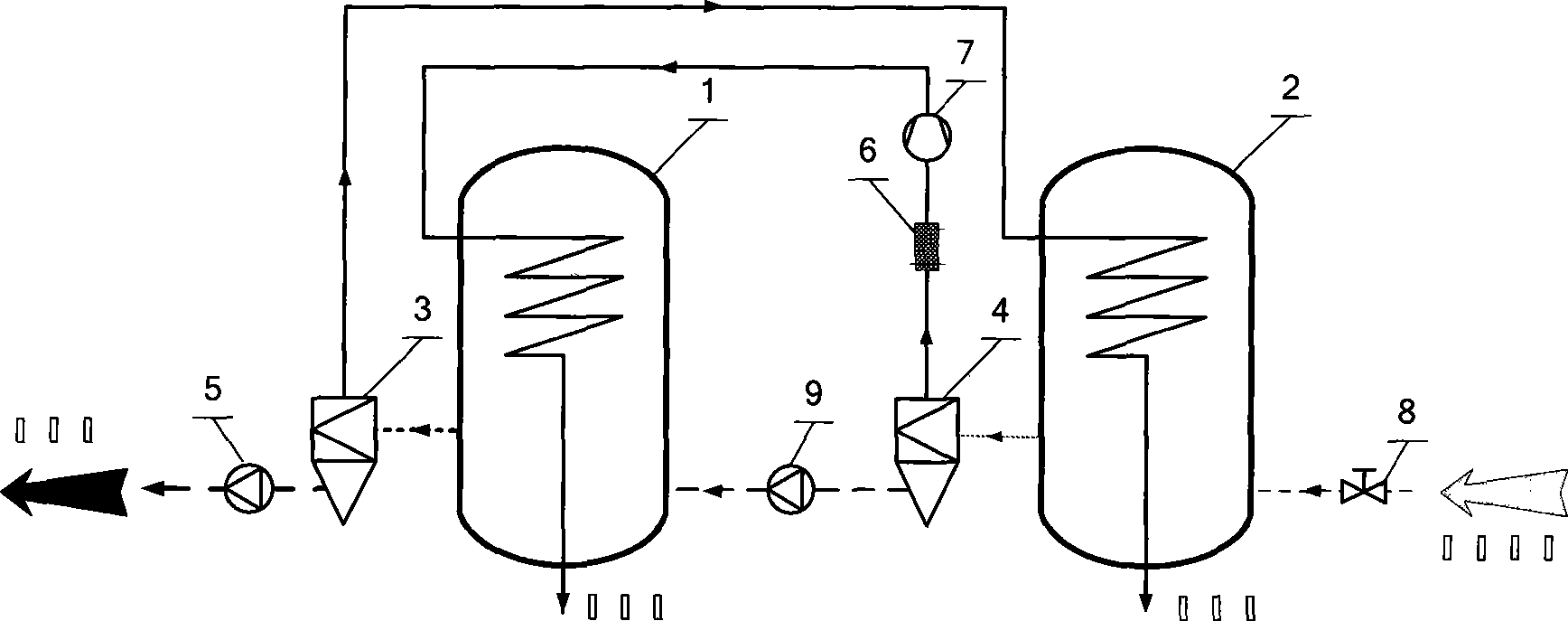

[0032] figure 2 It is the countercurrent feeding type alcohol fermentation grain liquid heat pump concentration device and process diagram of the present invention. The overall flow direction of the waste liquid is opposite to the flow direction of the heating steam, that is, the bad liquid with low concentration and temperature first passes through the low-pressure evaporator 2, and then passes through the high-pressure evaporator 2. Evaporator 1, therefore, what is heated by the heating steam with high temperature is the bad liquor with high concentration. Such as figure 2 As shown, the bad liquid conveying pipeline is connected to the inlet port of the inlet pressure regulating valve 8, the outlet port of the inlet pressure regulating valve 8 is connected to the lower feed liquid inlet port of the low-pressure evaporator 2 through a pipeline, and the upper feed liquid outlet port of the low-pressure evaporator 2 passes through The pipeline is connected to the inlet end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com