Method for preparing printed lid of aluminum easy open can

A technology of pop cans and can lids, which is applied in the direction of packaging/bundling items, containers, applications, etc., can solve the problems of backward production technology, high cost, and low production efficiency, and achieve improved material utilization, simple process flow, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

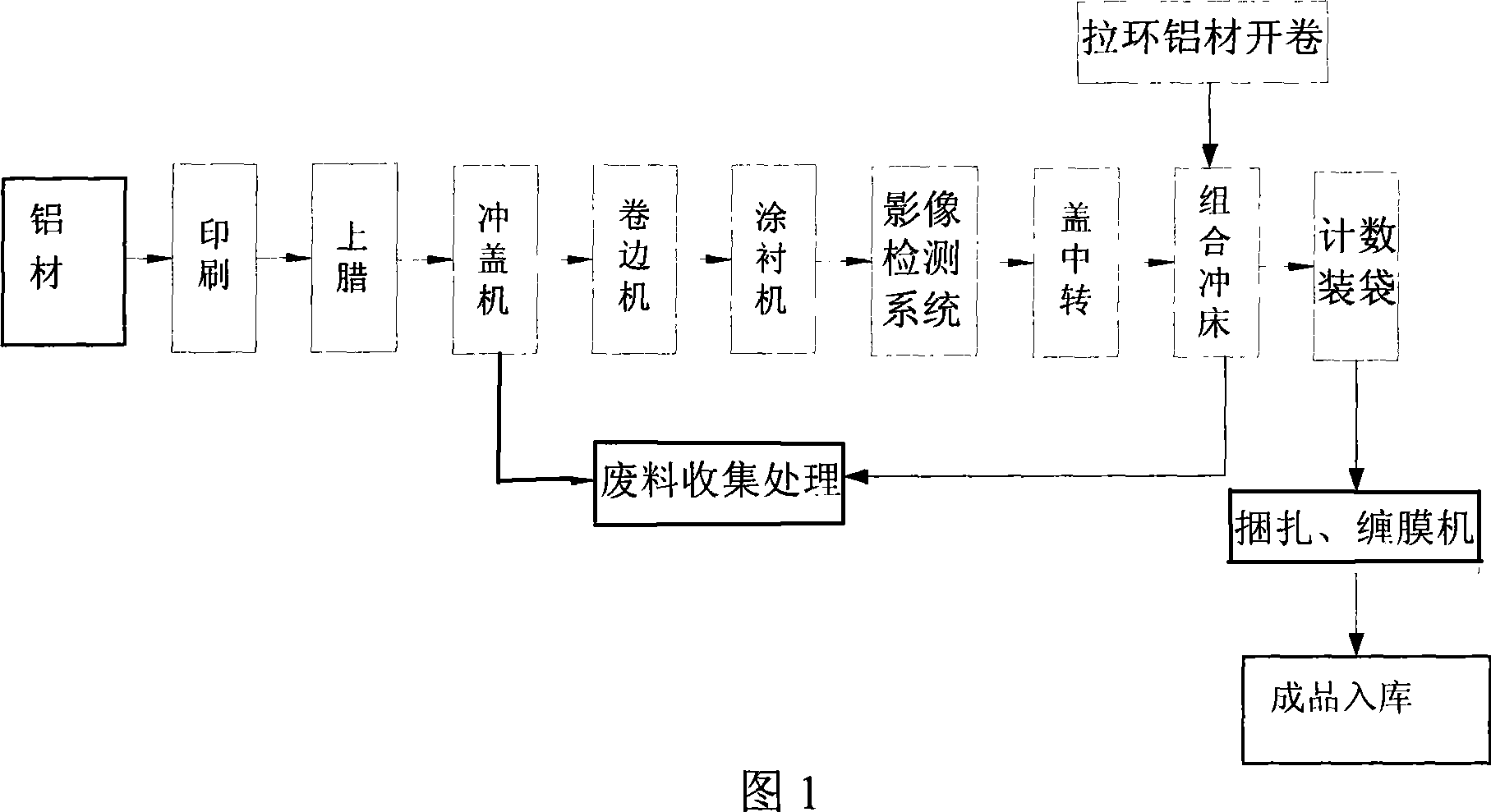

[0018] As shown in Figure 1, the preparation method of aluminum pop can printing can lid of the present invention comprises the following steps:

[0019] (1) Pretreatment of aluminum materials: Unwind and cut the coiled material for can lids into sheets for later use, print the specified pattern on the aluminum sheet according to actual requirements, and coat the inner paint on the upper and lower surfaces of the sheet, and the upper surface The thickness of the paint is 4 grams / square meter, the thickness of the lower surface paint is 11 grams / square meter, and then spray a layer of wax on the surface of each aluminum plate for lubrication;

[0020] (2) Punching cover: the aluminum material is punched into the shape of a can cover through a cover punching machine; the external dimensions of the can cover are required in the following table:

[0021] Hook outside diameter 64.82±0.15mm Hook opening ≥2.72mm

Hook Height +0.20

2.01—0.11mm collar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com