Aquosity short oil alkyd resin and preparation method thereof

An alkyd resin, short oil degree technology, applied in coatings, polyester coatings, etc., can solve the problems of hydrolysis resistance stability, flexible impact strength, and high cost of the paint film, avoiding poisoning failure, water resistance, etc. The effect of improved solution stability and stable synthesis reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

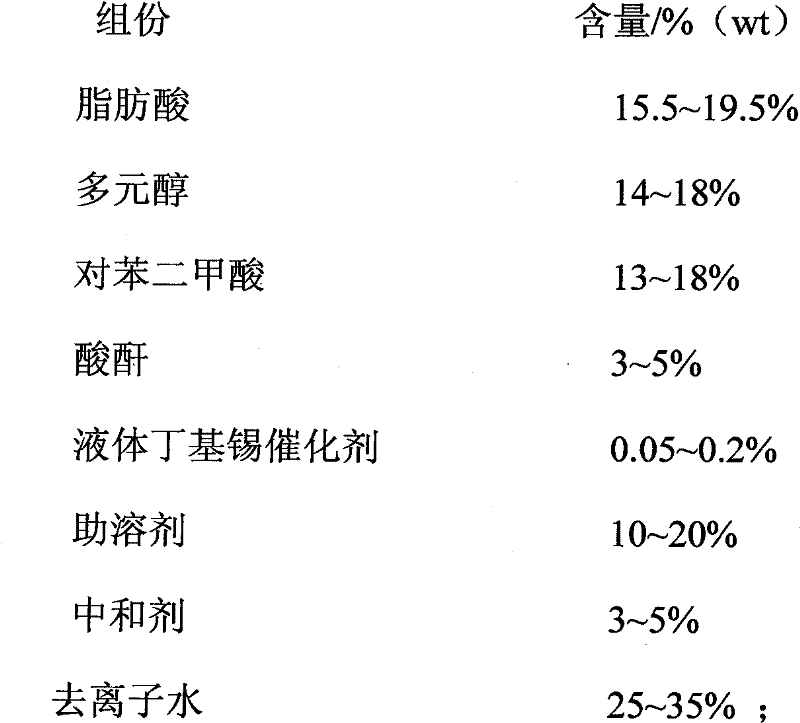

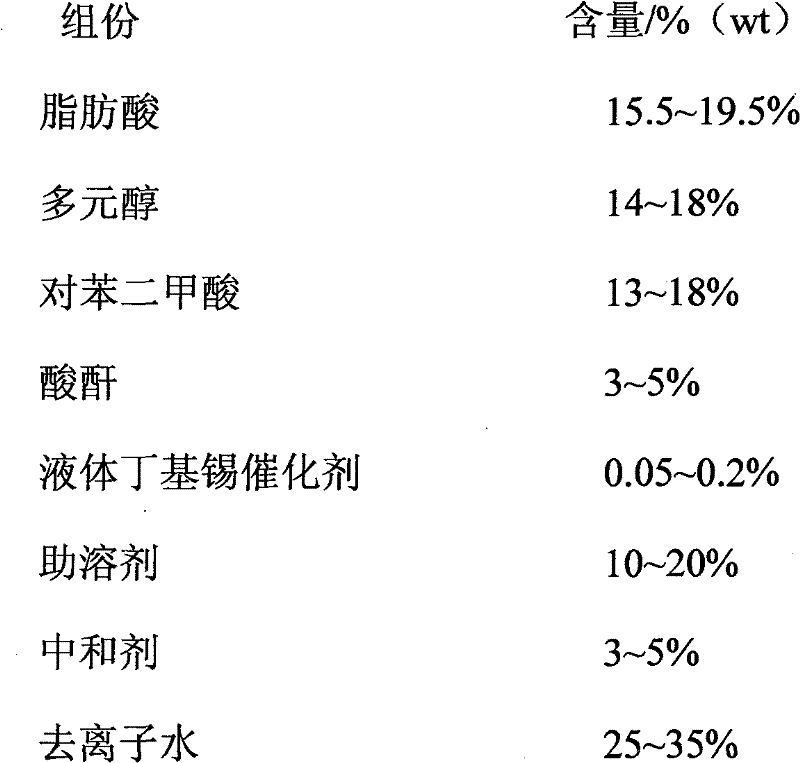

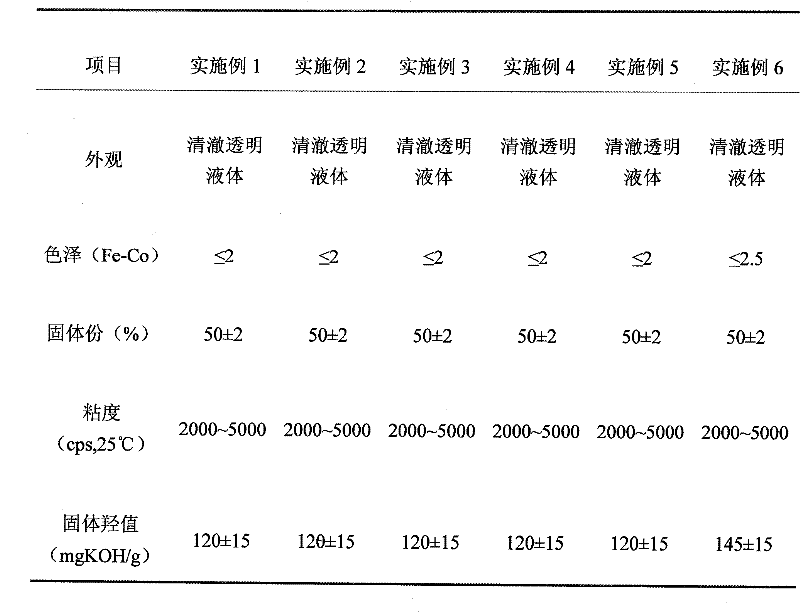

[0012] Embodiment 1: 17.88% coconut oil fatty acid, 16.79% trimethylolpropane, 13.99% terephthalic acid, add 0.1% liquid butyl tin catalyst, drop in the stainless steel reactor, seal the feeding port, open the air Valve, heat up and stir. When the temperature rises to 170°C, water begins to flow out, then continue to heat up to 220-230°C and keep it warm for 2-4 hours until the acid value is below 10mgKOH / g, then cool down to 175°C, add 3.64% partial anhydride, and keep warm at 170-180°C Carry out esterification reaction until the acid value is 45-55mgKOH / g, and the Grignard viscosity is 12-20s, then cool down, add 15.90% ethylene glycol butyl ether, 3.78% dimethylethanolamine and 27.92% deionized water and stir evenly . The whole process takes about 10-15 hours.

Embodiment 2

[0013] Embodiment 2: 15.58% coconut oil fatty acid, 17.44% trimethylolpropane, 15.74% terephthalic acid, add 0.1% liquid butyl tin catalyst, drop in the stainless steel reaction kettle, seal the feed inlet, open the air Valve, heat up and stir. When the temperature rises to 170°C, water begins to flow out, then continue to heat up to 220-230°C and keep the temperature for 2-4 hours until the acid value is below 10mgKOH / g, then cool down to 175°C, add 2.95% partial anhydride and 0.68% maleic anhydride, Keep warm at 170-180°C for esterification until the acid value is 45-55mgKOH / g, Grignard viscosity 12-25s, then cool down, add 10.25% propylene glycol methyl ether, 3.36% dimethylethanolamine and 33.9% Ionized water was stirred evenly. The whole process takes about 10-15 hours.

Embodiment 3

[0014] Embodiment 3: 17.04% of coconut oil fatty acid, 14.53% of pentaerythritol, 17.22% of terephthalic acid, plus 0.1% of liquid butyl tin catalyst, put into a stainless steel reactor, seal the feeding port, open the vent valve, heat up and stir . When the temperature rises to 170°C, water begins to flow out, then continue to heat up to 220-230°C and keep it warm for 2-4 hours until the acid value is below 10mgKOH / g, then cool down to 175°C, add 3.82% partial anhydride, and keep warm at 170-180°C Carry out esterification reaction until the acid value is 45-55mgKOH / g, Grignard viscosity is 15-30s, then cool down, add 7.90% propylene glycol methyl ether, 7.90% isopropanol, 3.60% dimethylethanolamine and 27.89% Deionized water and stir well. The whole process takes about 10-15 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com