Alkane cracking and fuel cell compound power generation system

A fuel cell and power generation system technology, applied in the energy field, can solve problems such as catalyst poisoning, low electrochemical activity, and affecting battery life, and achieve the effect of avoiding poisoning failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

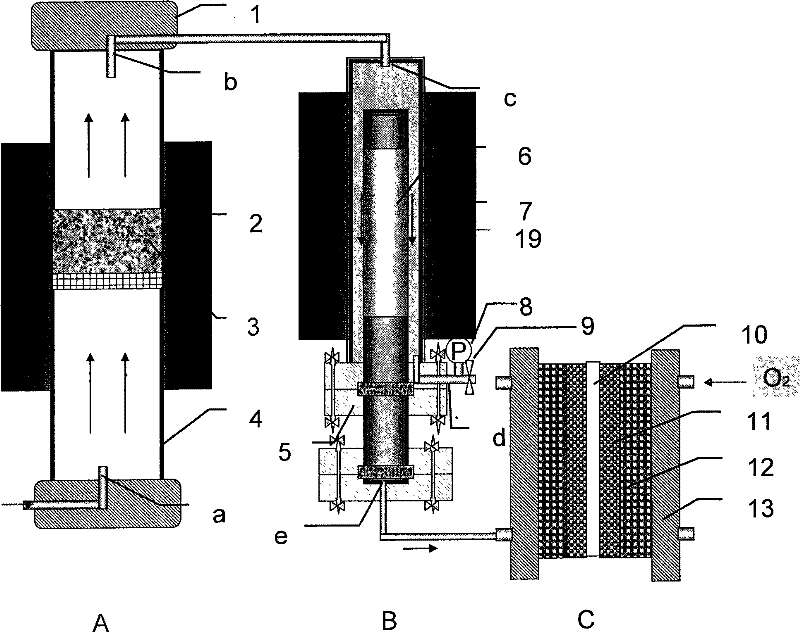

[0031] Example 1 Methane cracking hydrogen production and hydrogen separation fuel cell power generation system ( figure 1 shown)

[0032] 1. Installation of cracking catalytic device ( image 3 shown).

[0033] A quartz tube catalytic bed (length 50cm, diameter 30mm) is used. Alumina supports nickel as a catalyst to crack methane.

[0034] The amount of catalyst used was 2 g. A porous graphite plate is used as a fixed bed in a quartz tube, 6 g of quartz fragments are added to the catalyst as a dispersant, and the catalyst is poured into the quartz tube. The two ends of the quartz tube are sealed with a stainless steel ferrule, and the stainless steel ferrule has an inlet and outlet port to connect the gas.

[0035] 2. Installation of palladium membrane filtration device

[0036] Common commercial palladium membrane purchased (95% hydrogen permeation rate, gas permeable alumina tube as carrier.) The tube installation of palladium membrane adopts figure 1 shown.

[0037]...

Embodiment 2

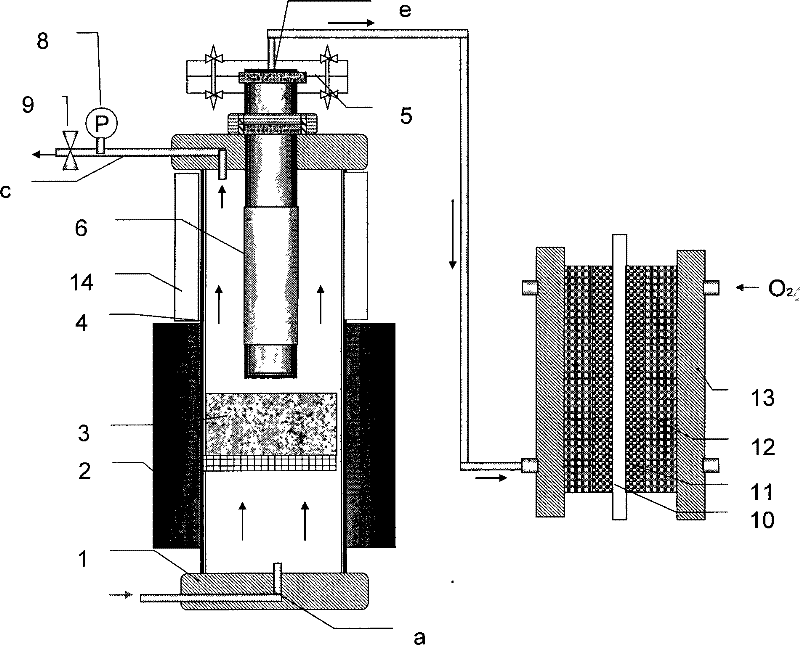

[0043] Example 2 Methane cracking hydrogen production and hydrogen separation integrated device ( figure 2 shown)

[0044] 1. Installation of cracking catalyst and palladium membrane filter.

[0045] A quartz tube is used to catalyze a fixed bed (length 80cm, diameter 45mm). Alumina supports nickel as a catalyst to crack methane.

[0046] The amount of catalyst used was 3 g. A porous graphite plate is used as a fixed bed in a quartz tube, 6 g of quartz fragments are added to the catalyst as a dispersant, and the catalyst is poured into the quartz tube. The lower end of the quartz tube is sealed with a stainless steel ferrule, and the stainless steel ferrule has an air inlet port to connect the gas.

[0047] The common commercial palladium membrane (diameter 10mm, length 20cm, 99% hydrogen permeation capacity, gas-permeable alumina tube is used as the carrier. The tube installation of the palladium membrane adopts Figure 5 shown. The heating electric furnace is used to h...

Embodiment 3

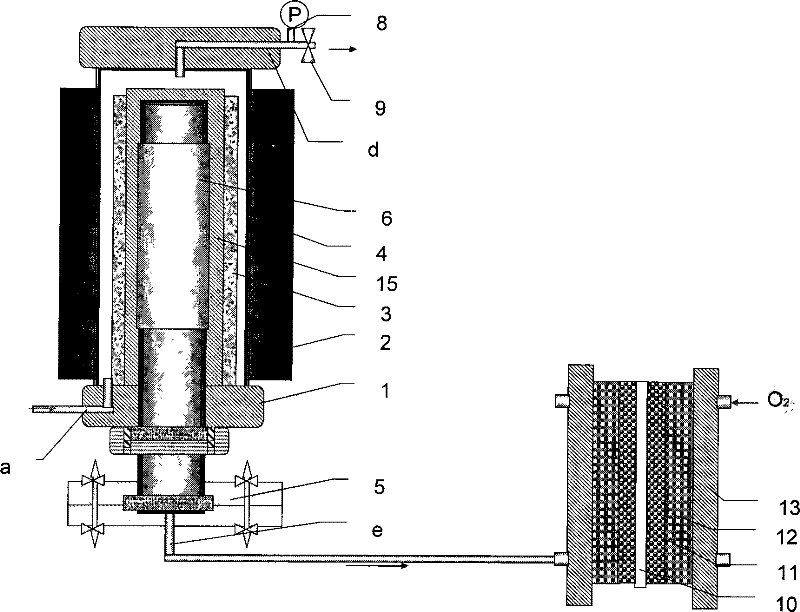

[0054] Example 3 Methane cracking hydrogen production and hydrogen separation integrated device ( image 3 shown)

[0055] 1. Installation of cracking catalyst and palladium membrane filter.

[0056] A quartz tube is used to catalyze a fixed bed (length 80cm, diameter 45mm). The lower end of the quartz tube is sealed with a stainless steel ferrule, and the stainless steel ferrule has an air inlet port to connect the gas.

[0057] Adopt the common commercial palladium film (diameter 10mm, length 20cm, 99% hydrogen permeation rate, air-permeable aluminum oxide tube to do carrier. The tube installation of palladium film adopts as shown in Figure 6. The external part of palladium film tube adopts porous ceramic tube to do insulation In the purification layer, a nickel catalyst that catalyzes methane is carried on the outside of the ceramic tube.

[0058] 2. The fuel gas inlet of the fuel cell is connected with the gas outlet of the palladium membrane. The fuel cell is a commerc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com