Method for removing coke powder in raw oil and device thereof

A raw material oil and coke powder technology, which is applied in the field of petroleum processing and clean production, can solve the problems of large equipment investment, inability to operate for a long period, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

[0059] PetroChina Dushanzi Petrochemical 10 million tons / year refinery 800,000 tons coke powder separation device

[0060] See the following table 1-2 for fluid properties:

[0061] Table 1, raw material composition and properties

[0062] Raw material type coker gasoline Coker diesel catalytic diesel Simulate Mixed Raw Materials Density at 20°C, g / m 3 0.72 0.84 0.8777 0.8201 Sulfur content, ppm wt 2654 4876 73...

Embodiment approach

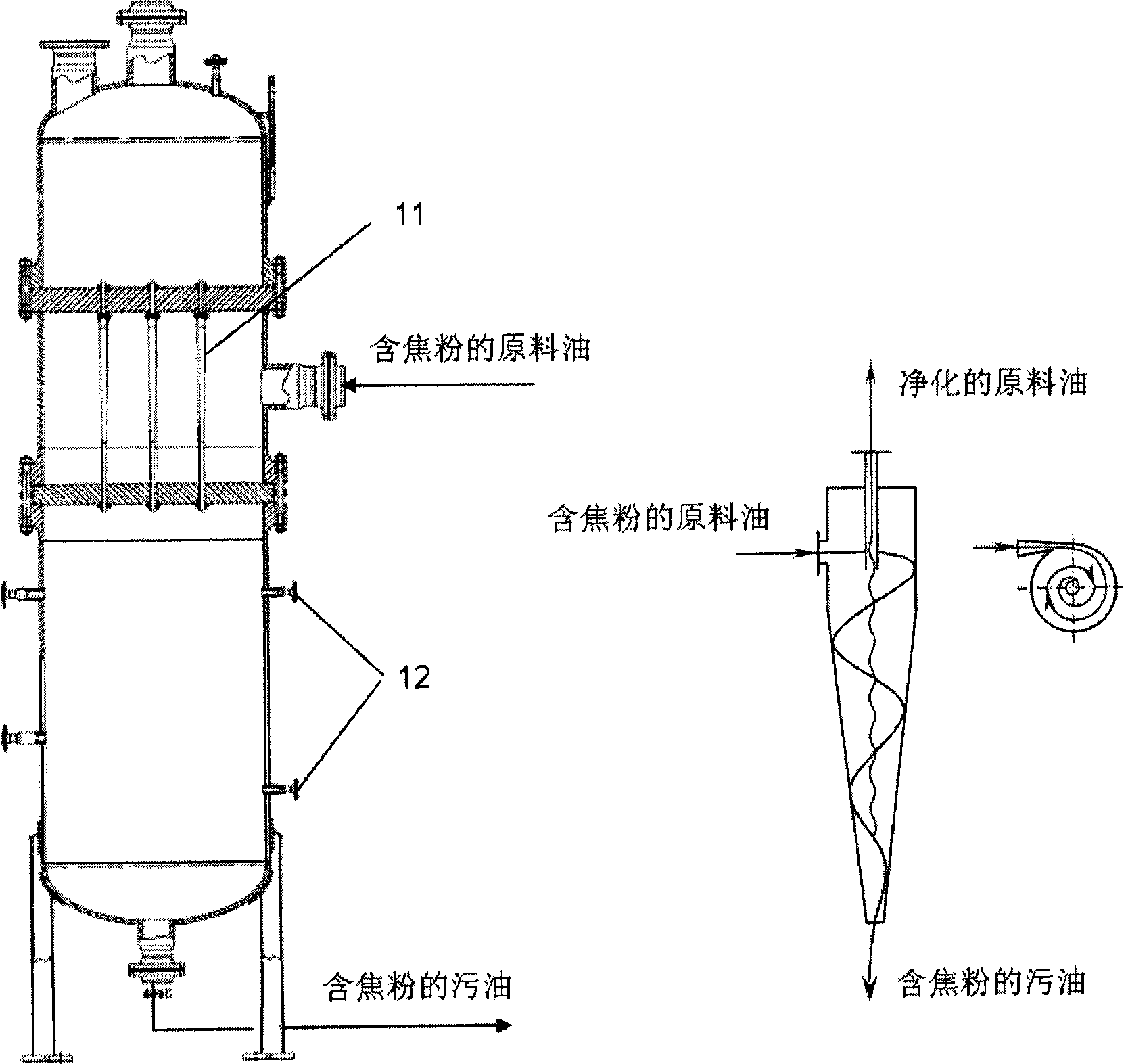

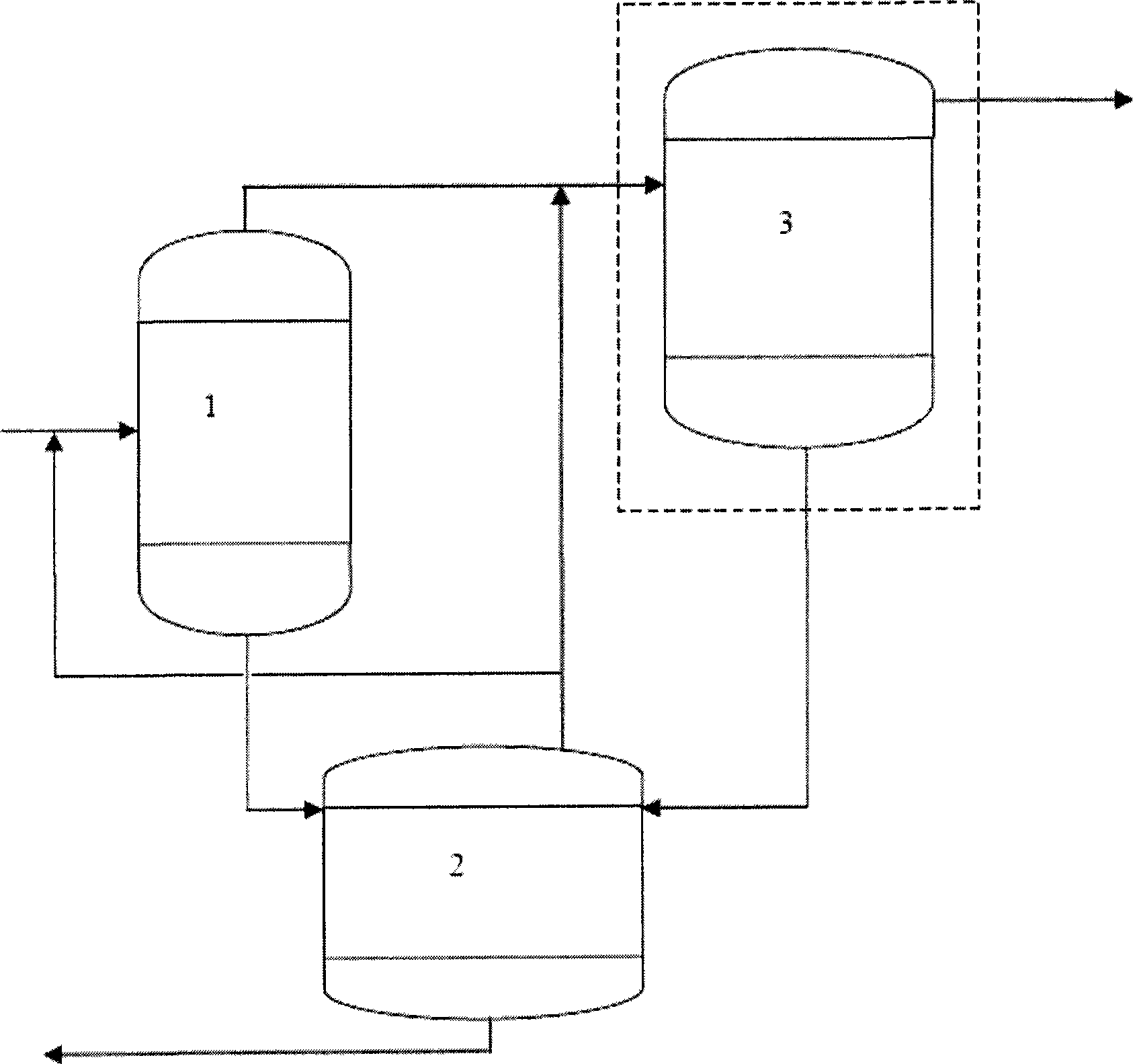

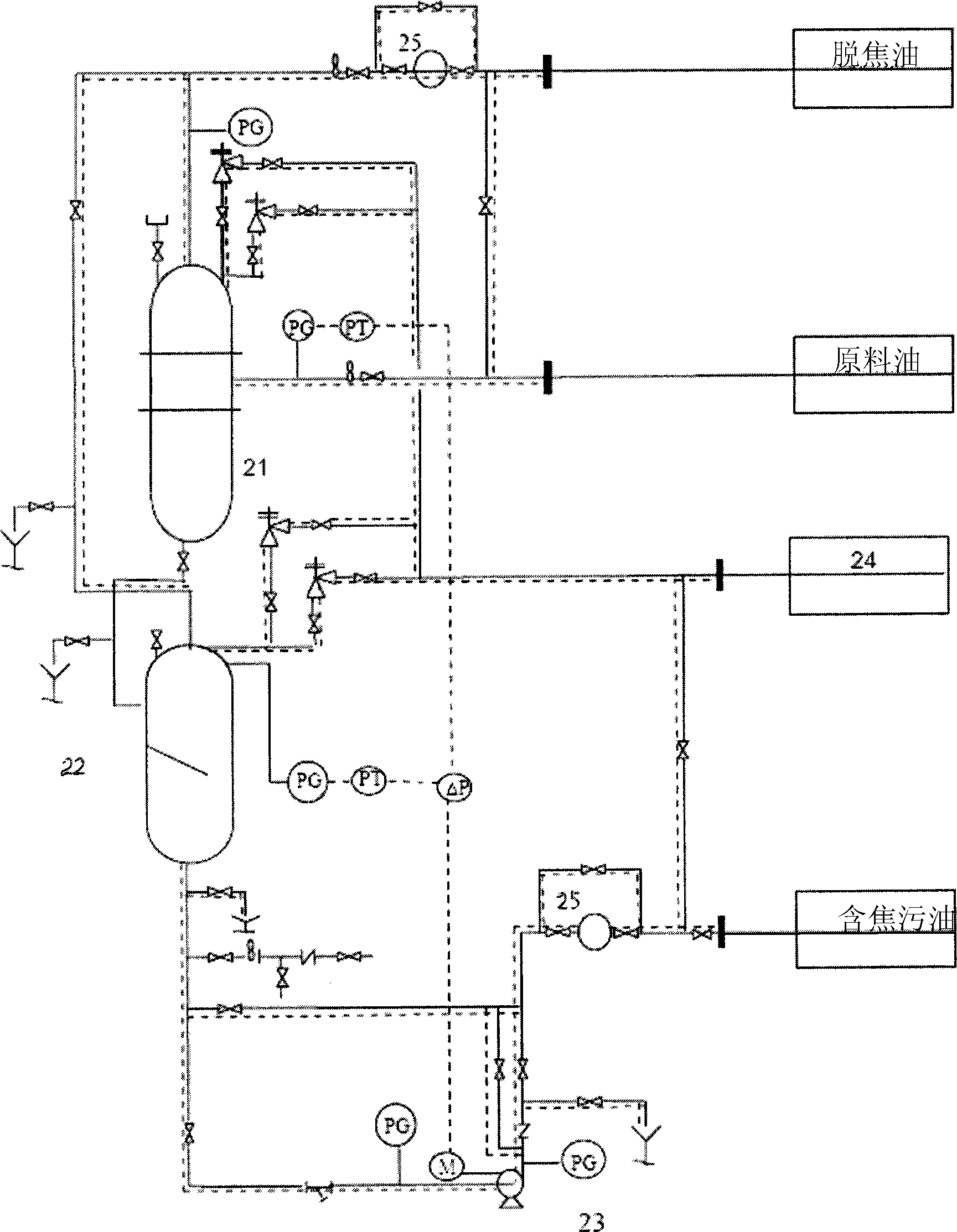

[0066] The 800,000 tons / year Dushanzi catalyzed diesel raw material oil was treated by cyclone separation and gravity sedimentation. First, the raw material oil is processed through the raw material oil decoking powder cyclone, and the purified raw material oil that overflows is sent to the follow-up device; the coke-containing powder and dirty oil that flows out from the bottom is sent to the settling tank for further treatment, and the raw material oil that is partially separated by the settling tank Go directly to the follow-up device, and the dirty oil enriched with coke powder after concentration is extracted out through the frequency conversion dirty oil pump 23. See the process flow image 3 . Process description:

[0067] (a) The coke powder separator 21 separates the raw material into a coke powder phase and an oil phase. The pressure drop between the outlet and the inlet of the oil phase is not more than 0.15MPa, and the pressure drop between the outlet and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com