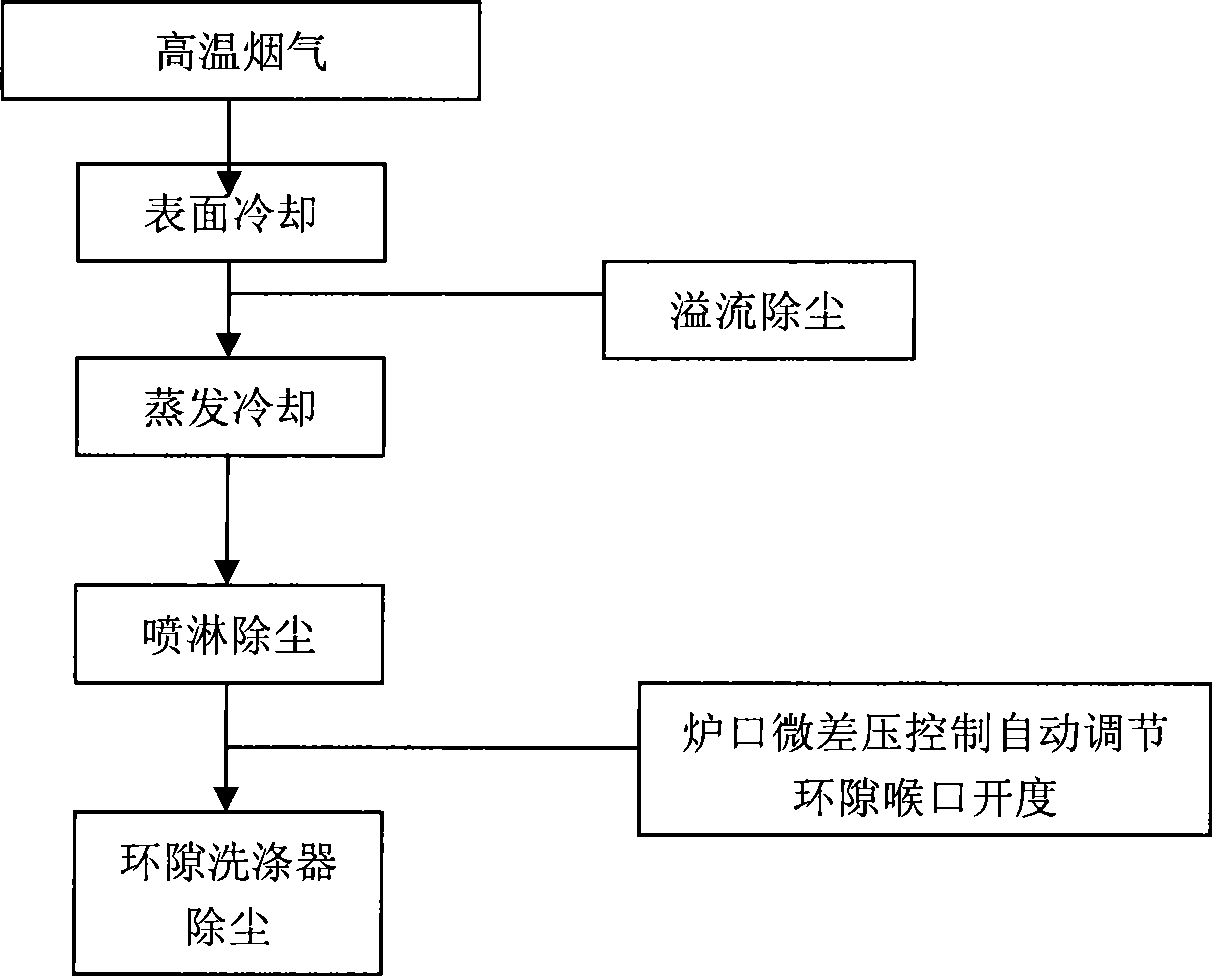

Converter gas wet cooling and dedusting method

A converter gas and wet process technology, applied in separation methods, chemical instruments and methods, manufacturing converters, etc., can solve problems such as easy blockage of RD throat, many equipment units, small adjustment range of throat flow area, etc., and achieve saving Power consumption and water consumption, the effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

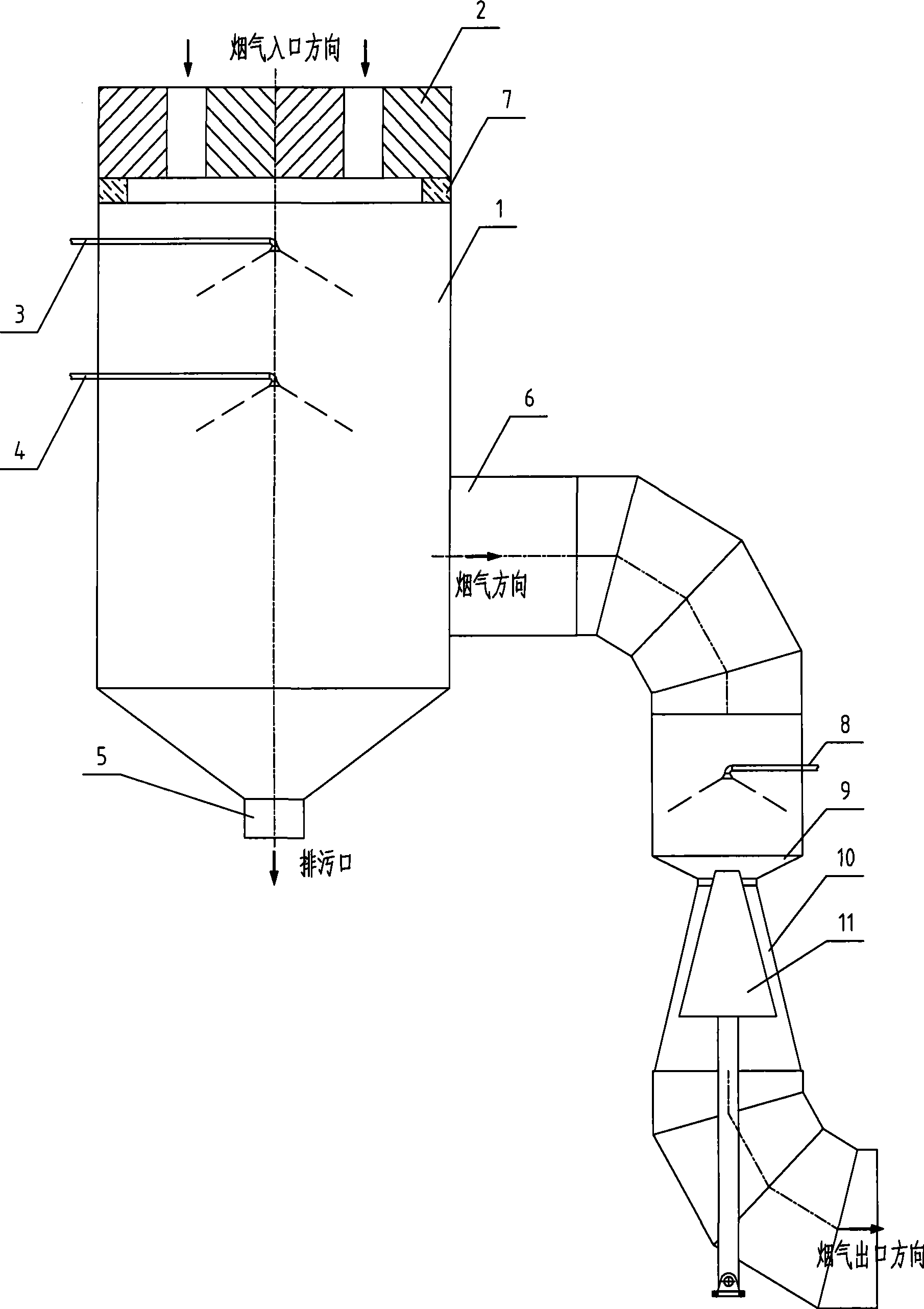

[0033] Such as figure 1 , 2 , the inventive method comprises the following steps:

[0034] 1) Evaporative cooling and spray dust removal,

[0035] 1-1) Evaporative cooling, sending the flue gas with a temperature of about 900°C into the dust removal equipment 1 (the dust removal equipment 1 is a cylindrical part) for cooling and dust removal, and spraying cooling water droplets with the nozzle 3, so that the cooling water droplets and heat The flue gas is mixed, evaporated and cooled, so that the temperature of the flue gas is rapidly reduced to 70-80°C; the particle size of the sprayed cooling water droplets is within 100 microns;

[0036] 1—2) Spray dust removal, the flue gas that has been evaporatively cooled is sprayed with nozzle 4 to collect dust particles, and the particle size of the sprayed water droplets is 100-250 microns; The sewage outlet 5 at the bottom of the equipment 1 is discharged; between the heat exchanger 2 and the entrance of the equipment 1, an overf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com