Exhaust gas recycling aerostatic bearing and design method thereof

An aerostatic bearing and design method technology, applied to bearings, shafts and bearings, mechanical equipment, etc., can solve problems affecting the measurement accuracy of instruments and equipment, eliminate the impact of gas disturbance on the measurement environment, improve measurement accuracy, and optimize structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

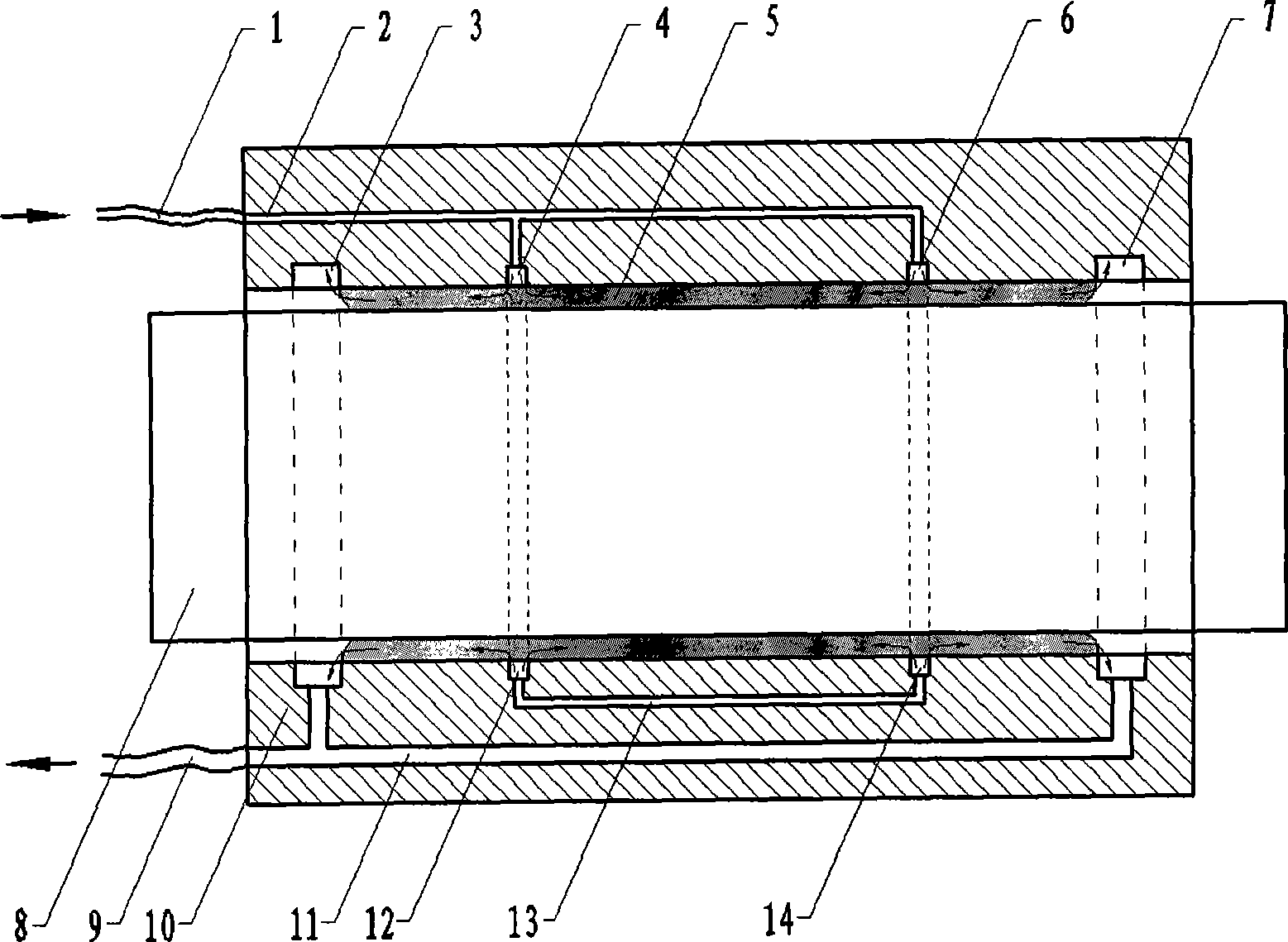

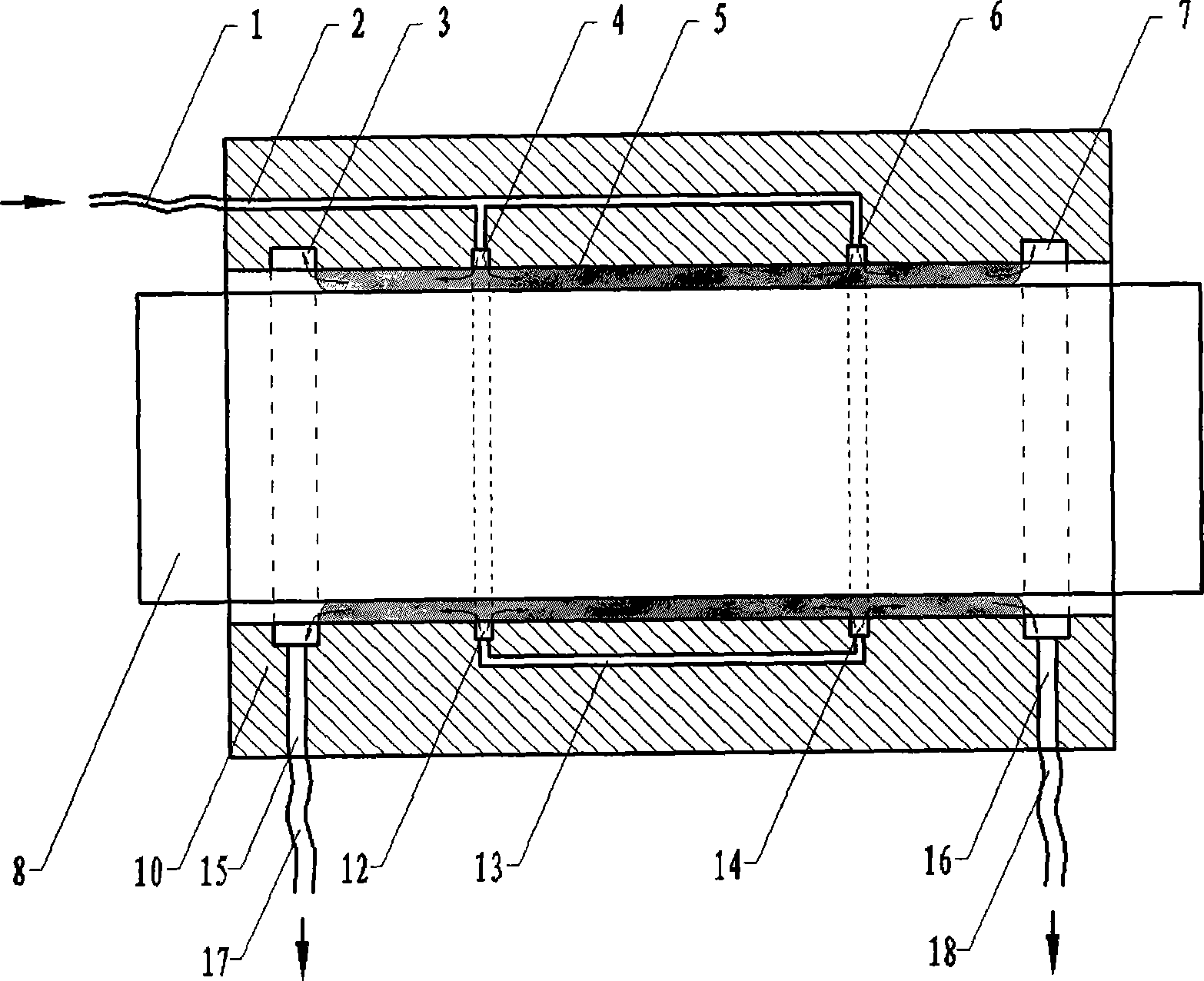

Embodiment 1

[0028] The structure of Embodiment 1 of the present invention is as Figure 5 As shown, an aerostatic linear bearing device that can recover exhaust gas includes an external air supply pipe 1, an external exhaust pipe 9, a main shaft 8, and a bearing sleeve 10. Air supply holes 4, Air supply hole 12, air supply hole 6, air supply hole 14, zero pressure groove loop 3, zero pressure groove loop 19, zero pressure groove loop 7, when the bearing is working, the adjacent zero pressure groove loop 3, zero pressure groove loop A high-pressure area 5 and a high-pressure area 20 are formed between the pressure groove loop 7, the zero-pressure groove loop 7, and the zero-pressure groove loop 19, and an air supply pipeline 2, an air supply loop 13, and an exhaust pipeline are arranged inside the bearing sleeve 10. 11. The air supply circuit 13 connects the air supply hole 4, the air supply hole 12, the air supply hole 6, and the air supply hole 14. The external air supply pipe 1 and the ...

Embodiment 2

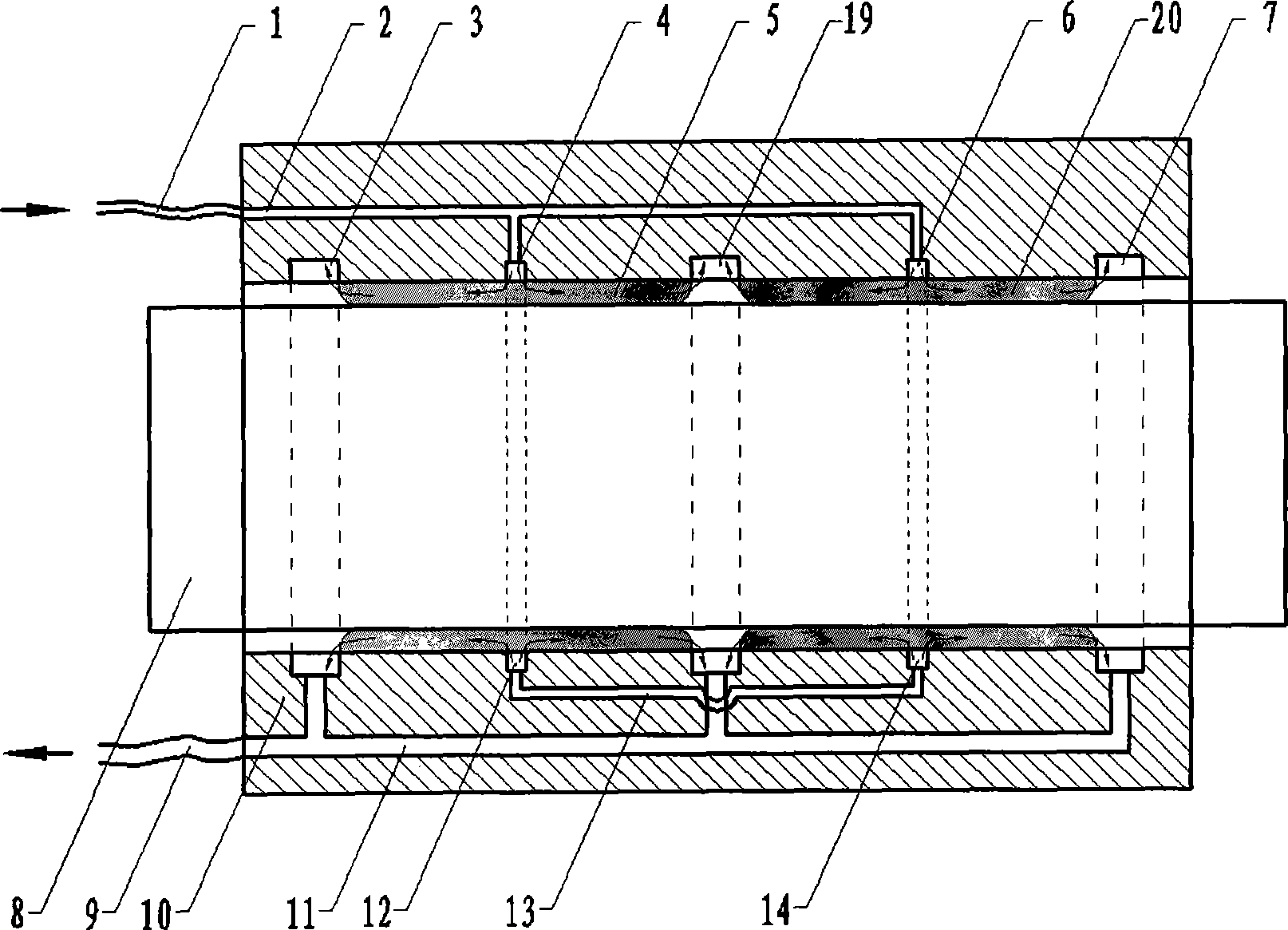

[0031] The structure of Embodiment 2 of the present invention is as Figure 6 As shown, the difference from Example 1 is that the main shaft 8 is circular, and the high-pressure air enters the air supply pipe 2 from the external air supply pipe 1, flows in the air supply circuit 13, and passes through the air supply hole 4, the air supply hole 12, and the air supply hole 6. , the air supply hole 14, the outflow bearing sleeve 10 is sprayed to the surface of the main shaft 8, under the action of gas pressure, the main shaft 8 is separated from the bearing sleeve 10, and the high-pressure gas enters the gap between the main shaft 8 and the bearing sleeve 10 and forms a high-pressure zone 5, High pressure zone 20. When the bearing is working, an extremely thin layer of gas lubricating film is formed between the main shaft 8 and the bearing sleeve 10, and the main shaft 8 can rotate in the bearing sleeve 10 almost without friction, and the working process is the same as that of em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com