GM-III composite wind pipe construction method

A technology of composite air duct and construction method, which is applied in the direction of pipeline arrangement, etc., can solve the problem that the construction process and construction points are not formulated and disclosed, and achieve the effects of high worker proficiency, high labor productivity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

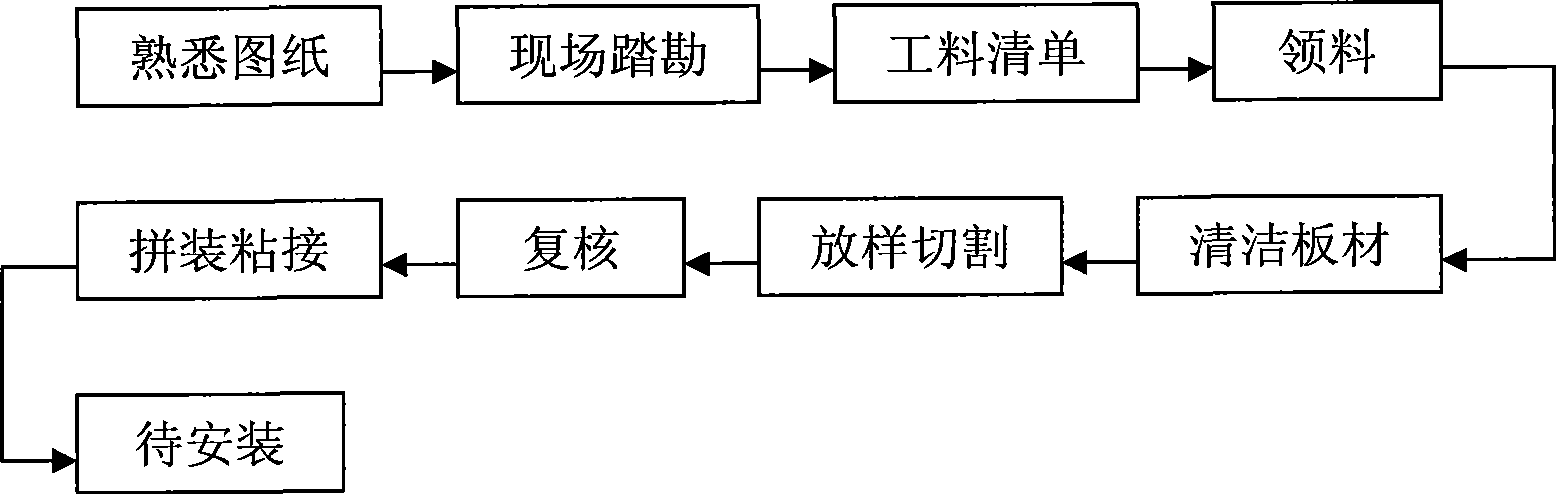

[0020] like figure 1 As shown, first of all, be familiar with the drawings and site survey, and then sort out the bill of materials and prepare the materials. Clean all the duct plates used, and then loft and cut them, and clean the cut edges after cutting. The key points of composite air duct blanking are as follows:

[0021] 1) The cutting line should be straight, and the error of the diagonal length of the air duct plate should be less than 5mm.

[0022] 2) After cutting, clean the cut edges.

[0023] 3) The cutting board must form a 90° angle with the panel.

[0024] After the cutting is completed, check the cut panels to be assembled, that is, check whether their length, width and adjacent side angles meet the requirements.

[0025] Assemble and glue the cut panels. The main points of composite air duct prefabrication are as follows:

[0026] 1) Prepare magnesium oxide powder and magnesium oxide halogen flakes at a weight ratio of 10:6, dissolve the halogen flakes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com