Preparation method for metal keystroke panel with multi-group micropores

A production method and technology of metal sheets, which are applied to electrical components, electric switches, circuits, etc., can solve problems such as dust accumulation or water infiltration, metal key panel appearance visual dullness, time-consuming and labor-intensive production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical content of the present invention is described in detail below in conjunction with accompanying drawing:

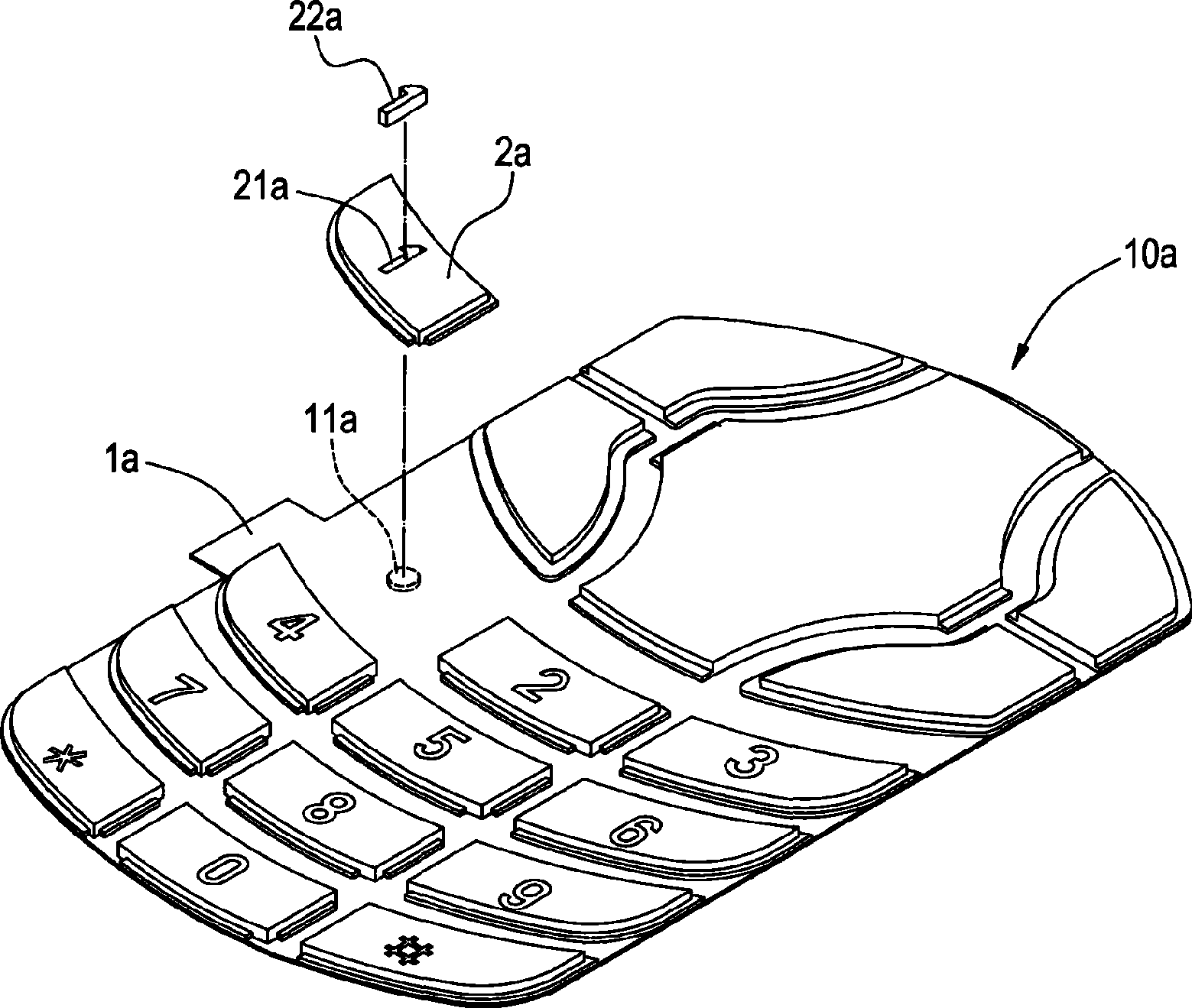

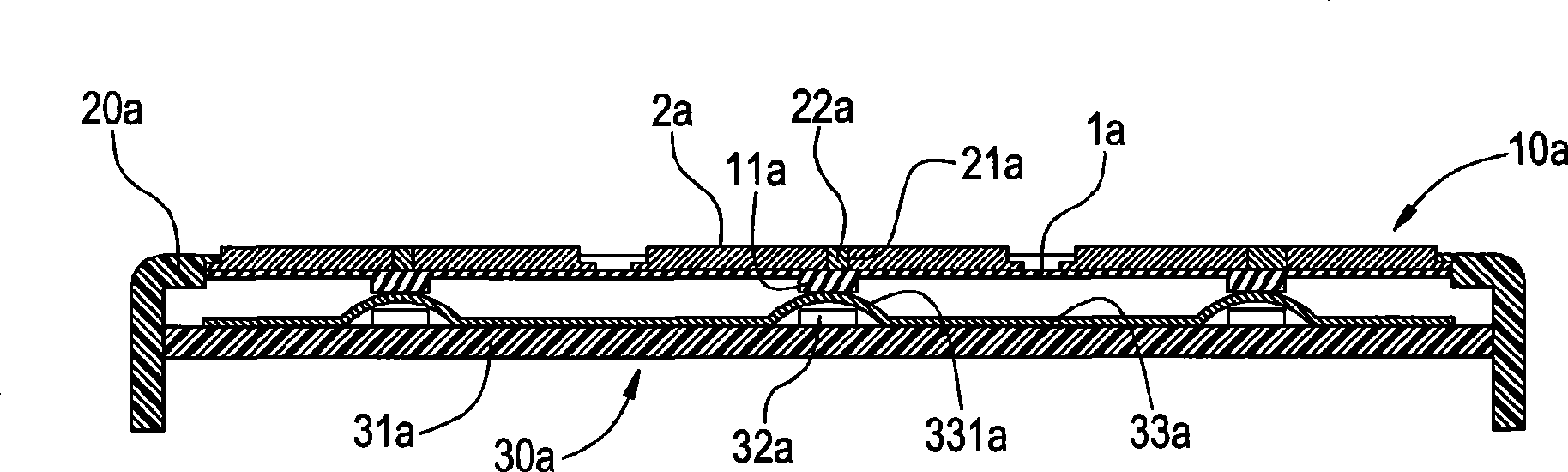

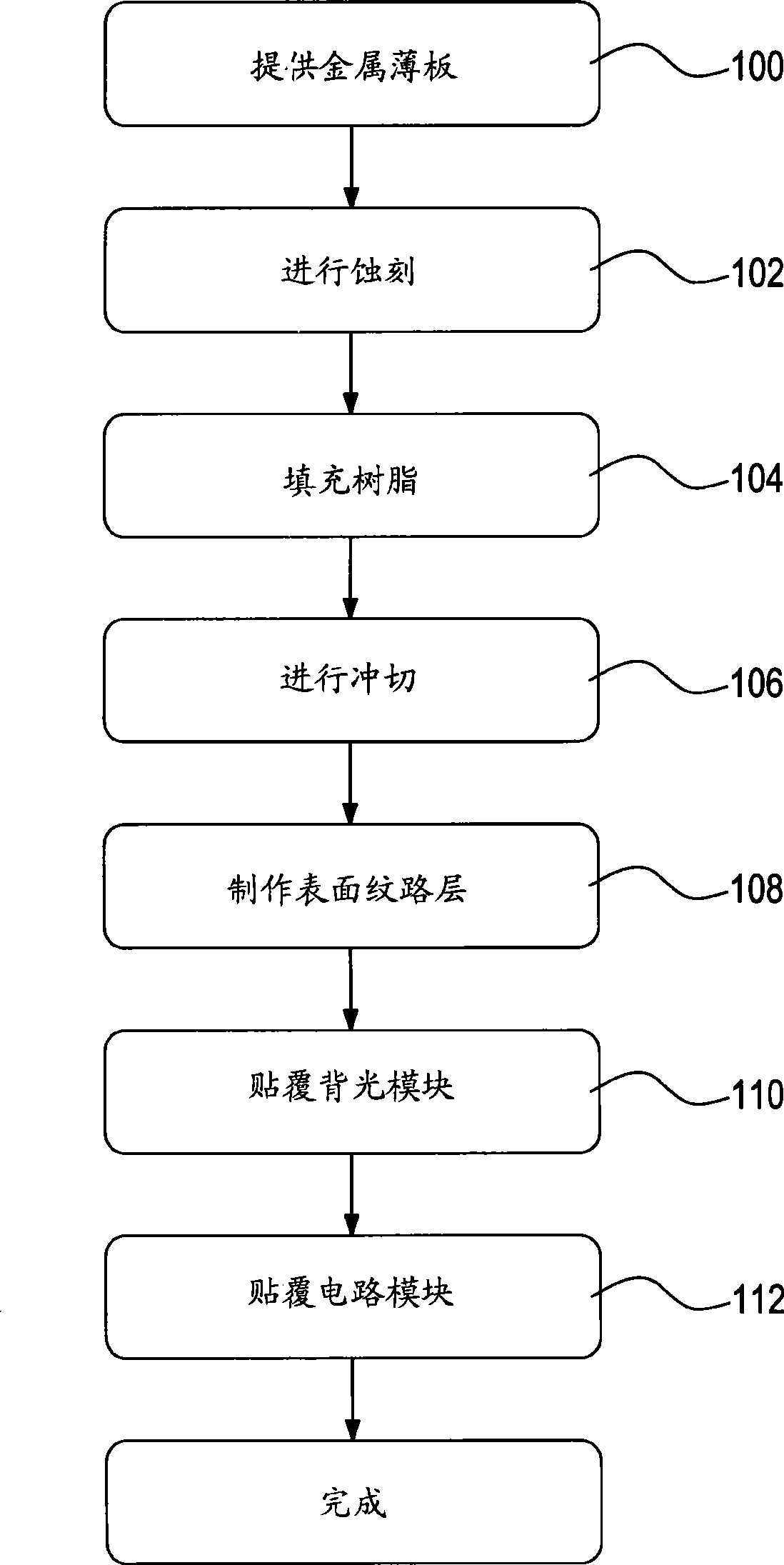

[0044] see figure 2 , which is a schematic diagram of the manufacturing process of the metal key panel of the present invention. As shown in the figure: according to the manufacturing method of the metal button panel with multiple groups of micropores of the present invention, at first in step 100, a metal sheet 10 (as shown in Figure 3 (a)) is provided, and the metal sheet 10 is made of stainless steel (SUS ) or made of aluminum-magnesium alloy.

[0045] Step 102, performing etching: performing etching treatment on the thin metal plate 10, so that multiple groups of micropores 11 are formed on the metal thin plate 10, and the arrangement of the multiple groups of micropores 11 makes a mesh-shaped metal key panel 1, as shown in Figure 3(b) shown.

[0046] Step 104 , filling the micropores: coating the filler 2 on the surface of the metal key panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com