Stirring transfer car and stirring drum control device

A mixing transport vehicle and control device technology, which is applied in the direction of control devices, cement mixing devices, clay preparation devices, etc., can solve problems such as the inability to realize the constant speed function of the mixing drum, and achieve the effect of meeting the control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

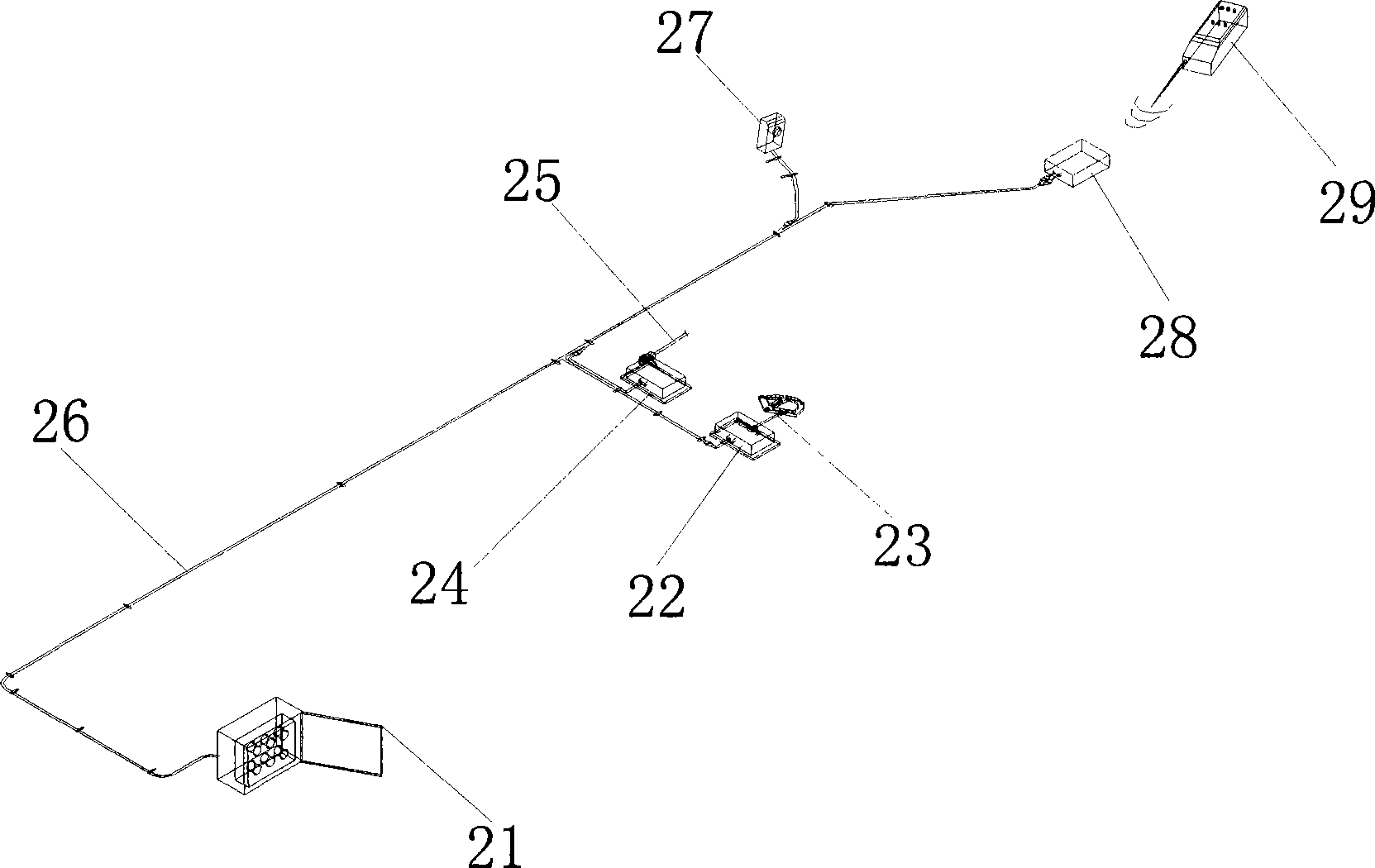

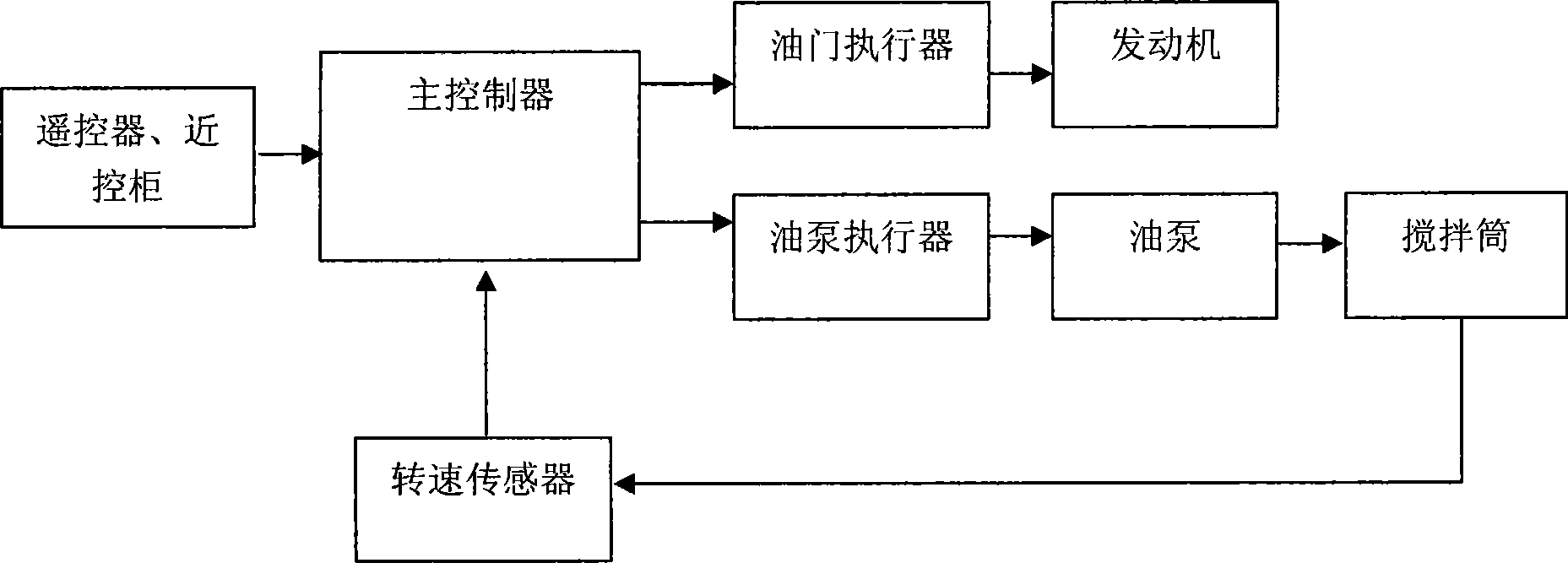

[0072] Please refer to figure 2 , is a schematic diagram of the composition of the electronic control operating system of the present invention, as shown in the figure, the electronic control operating system is mainly composed of a close control cabinet 21, an oil pump actuator 22, an oil pump variable lever 23, an accelerator actuator 24, an accelerator cable 25, and a control wire harness 26 , speed sensor 27, remote controller 29, controller 28, etc., its main function is to control the rotation angle of the oil pump actuator 22 and the throttle actuator 24 pull rod through the electronic controller to control the rotation angle of the mixing drum in forward, reverse, middle Position stop and engine acceleration and deceleration functions, so as to complete the feeding, stopping and discharging functions of the mixer truck, and through advanced microcomputer technology, sampling the speed pulse of the hydraulic motor, and constantly adjusting the rotation angle of the 22 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com