Step-by-step condensation regeneration method of cracking carbon five extraction solvent dimethylformamide

A technology of dimethylformamide and extraction solvent, which is applied in the field of regeneration of dimethylformamide, the extraction solvent of cracked C5 fraction, to achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

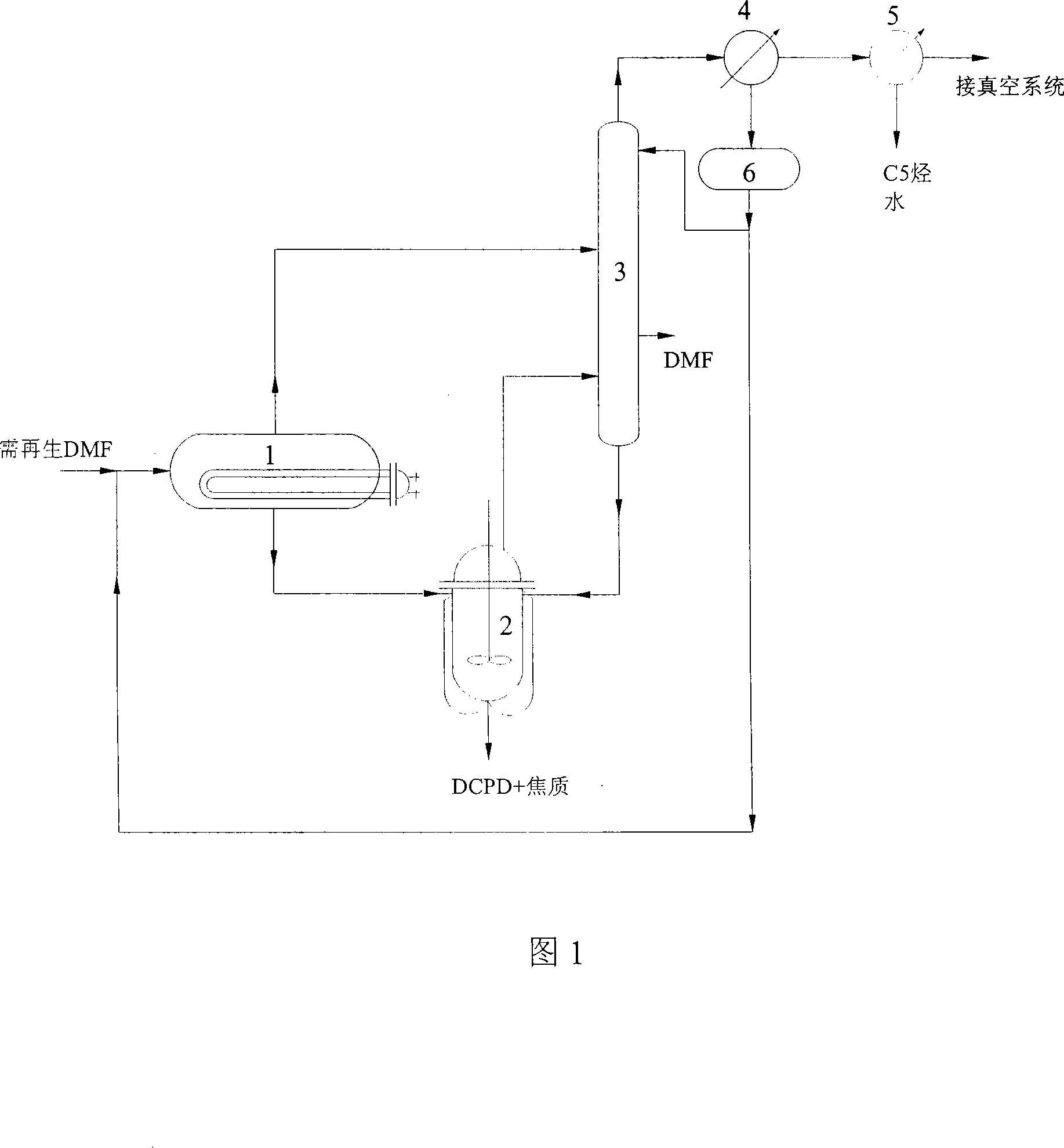

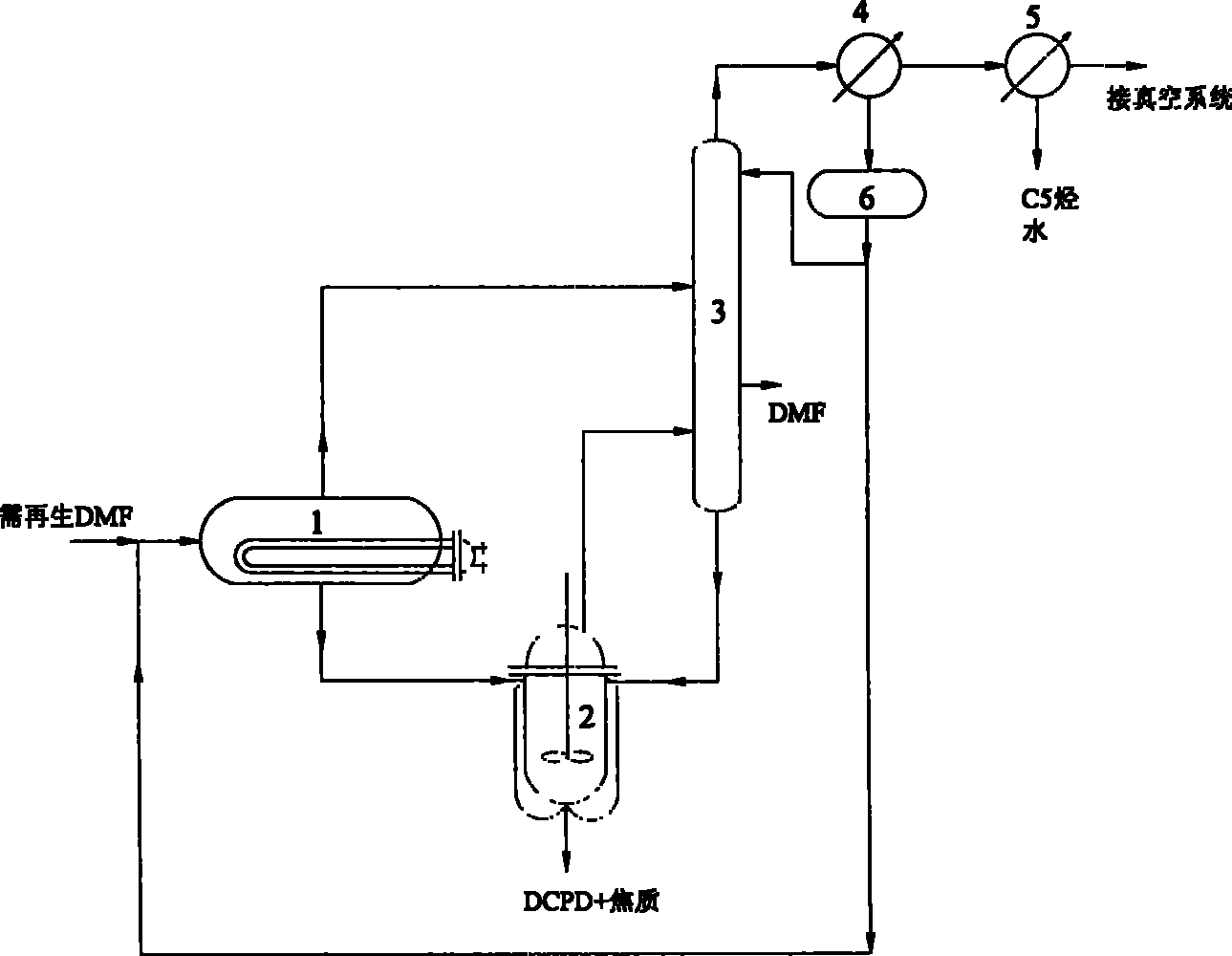

Image

Examples

Embodiment 1

[0039] Utilize the regeneration method of the present invention to process the cracked C5 fraction extraction solvent dimethylformamide that needs to be regenerated, and the dimethylformamide that needs to be regenerated mainly consists of the following:

[0040] components Composition, % by weight carbon pentacarbon 0.4 water 0.30 DMF 89.66

[0041] Dicyclopentadiene DCPD 5.21 Carbon pentadimer X3 1.89 colloid 2.54

[0042] (1) The extraction solvent dimethylformamide that needs to be regenerated enters the solvent regeneration kettle 1, and the vapor phase stream is extracted from the solvent regeneration kettle 1 top through vacuum distillation, and the liquid stream containing impurities is extracted from the lower end; the temperature of the solvent regeneration kettle 1 is controlled at 90℃, the pressure is controlled at 0.008MPa;

[0043] (2) The solvent refining tower has 50 trays in total, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com