Electronic control cylinder fuel-injection pump system

An oil injection pump and cylinder technology, applied in the direction of pressure lubrication of lubricating pumps, can solve the problems of difficulty in precise quantitative, timed oil injection, low oil injection pressure of mechanical oil injector, and inability to oil injection frequency, etc., to reduce harmful emissions and operating costs. , easy to promote, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

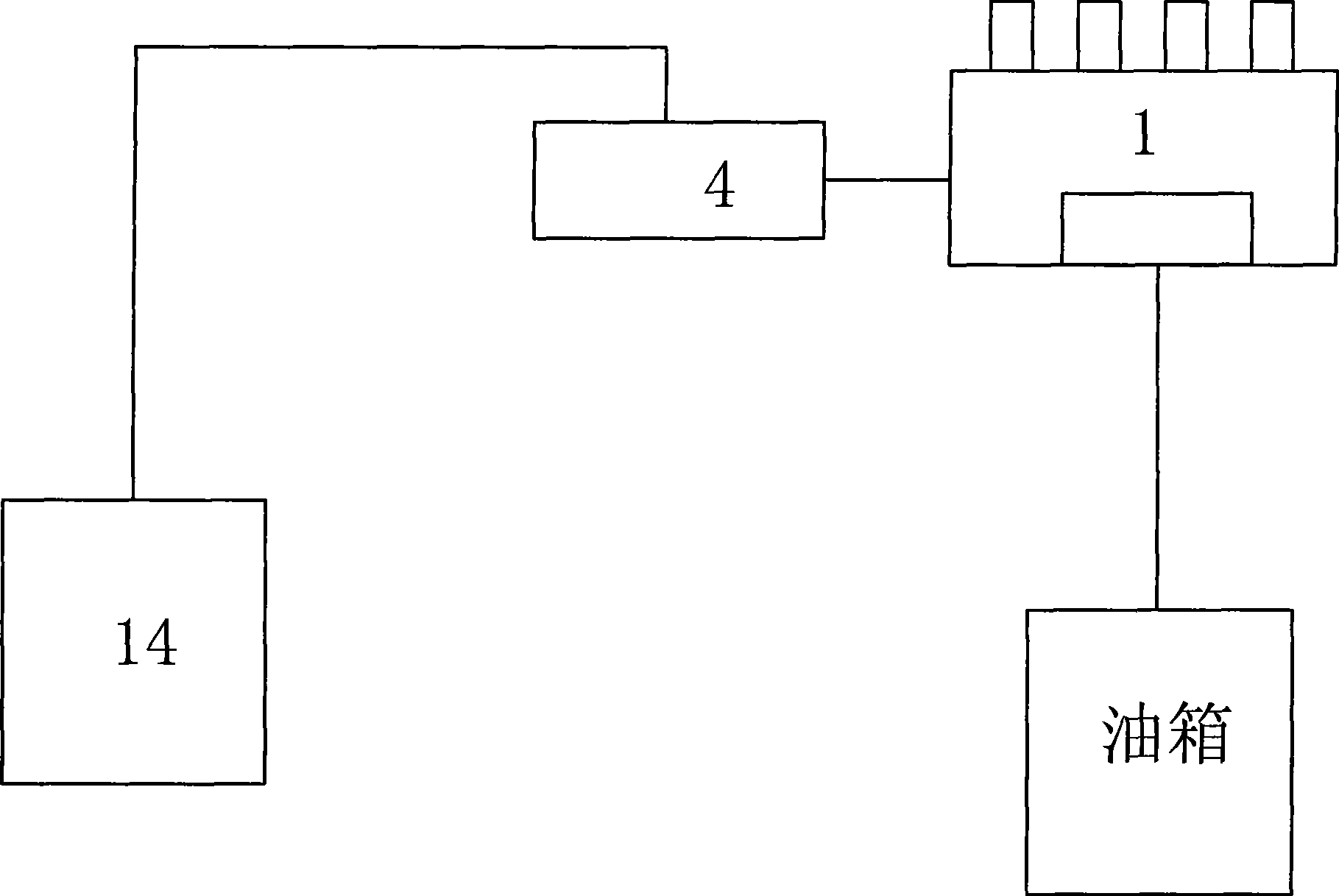

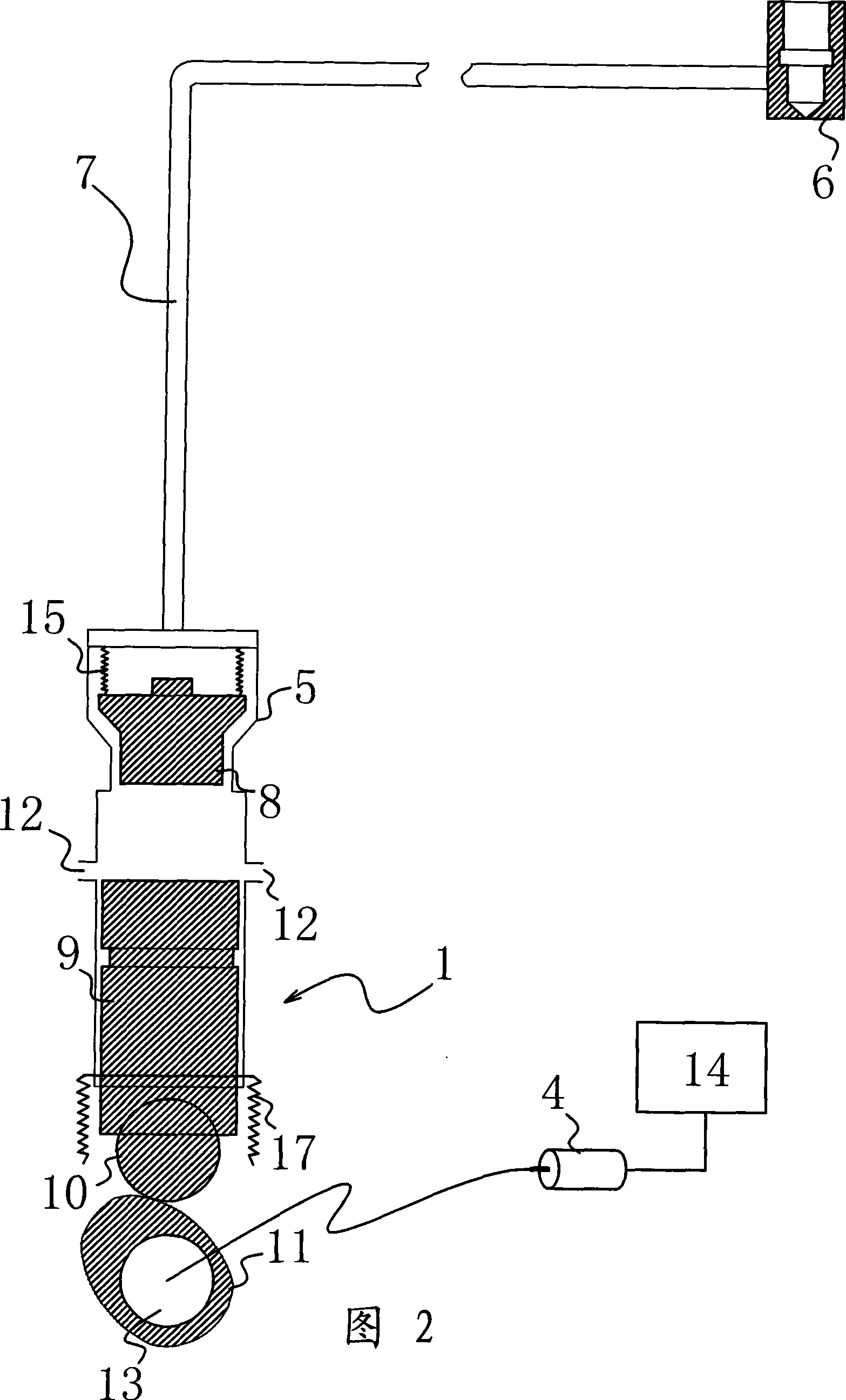

[0019] An example of this electronically controlled cylinder oil pump system is a system consisting of an oiler 1, a stepper motor 4 connected to the oiler 1 through a connecting device, and a controller 14 for controlling the operation of the stepper motor 4.

[0020] The oil injection unit includes the cylinder block 5 of the plunger cylinder and the oil pipe 7 with one end communicating with the cylinder block 5 and the other end connected with the nozzle 6. The cylinder block 5 is provided with an oil discharge valve spring 15 to press it against the cylinder block 5 to discharge oil. The drain valve 8 on the valve seat, the cylinder body 5 is a plunger 9 that can slide up and down in the cylinder body 5, the lower part of the plunger is provided with a roller, and the roller 10 is in line contact with the cam 11 under the cylinder body 5. When the oil drain valve 8 is opened, the lubricating oil flows out of the cylinder 5 through the oil drain port, and leads to the nozzle 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com