Hydraulic synchronous driving system based on pressure feedback

A technology of hydraulic synchronization and drive system, applied in the direction of fluid pressure actuating device, servo motor, mechanical equipment, etc., can solve the problem that the asynchronous error cannot be eliminated and the consistency requirements are high, and achieve the reduction of consistency requirements and strong anti-interference ability. , the effect of reducing system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

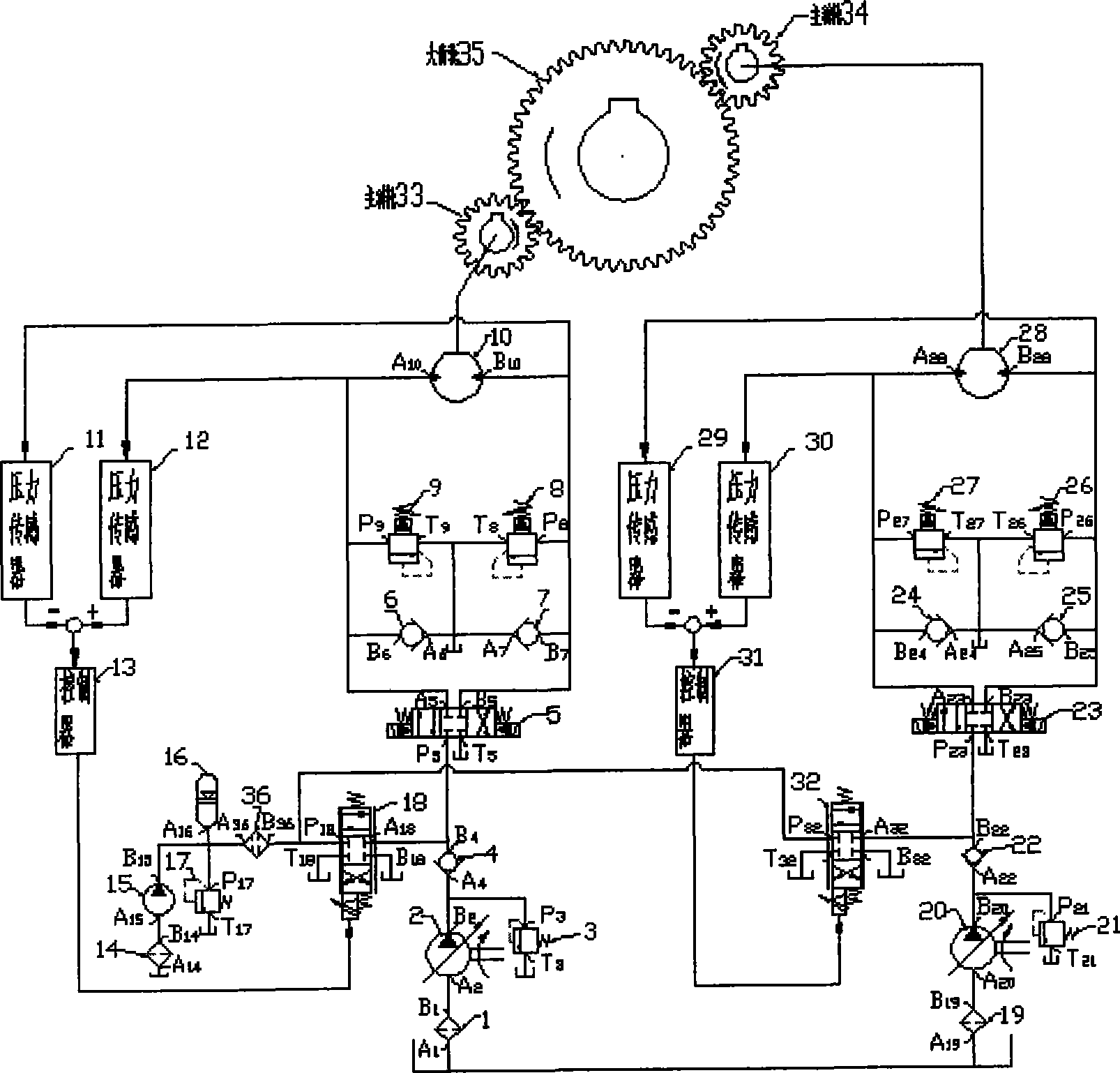

[0011] As shown in the drawings, the present invention includes four pressure sensors 11, 12, 29, 30, two controllers 13, 31, three filters 1, 14, 19, quantitative pump 15, accumulator 16, fine filter device 36, three overflow valves 3, 17, 21, two servo valves 18, 32, two variable displacement pumps 2, 20, six check valves 4, 6, 7, 22, 24, 25, two three Four-position electro-hydraulic reversing valve 5, 23, four proportional relief valves 8, 9, 26, 27, two motors 10, 28, two small gears 33, 34, large gear 35; the first filter 1 oil inlet A 1 Connected to oil tank; oil outlet B of first filter 1 1 With the oil inlet A of the first variable displacement pump 2 2 Connected; oil outlet B of the first variable displacement pump 2 2 Respectively with the oil inlet P of the first relief valve 3 3 , the oil inlet A of the first one-way valve 4 4 Connected; return port T of the first relief valve 3 3 Connected with oil tank; oil outlet B of the first one-way valve 4 4 Respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com