Submerge self-adapting gas seal device for photoetching machine

A gas-tight, self-adaptive technology, applied in the direction of photolithography exposure equipment, microlithography exposure equipment, etc., can solve the problems of increasing liquid bubble entrainment, liquid leakage, and easy leakage, so as to increase the speed of substrate movement and ensure High stability, the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

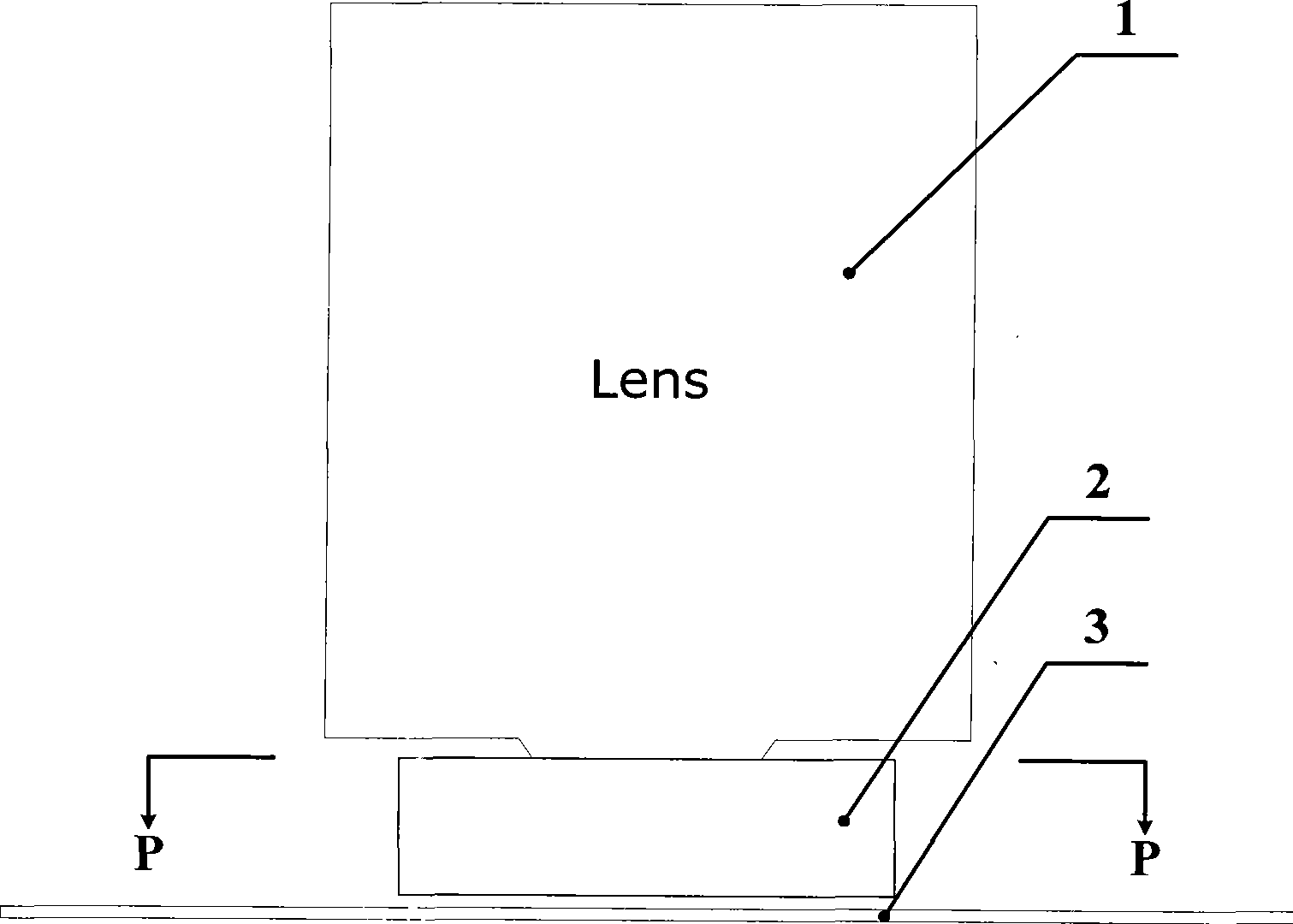

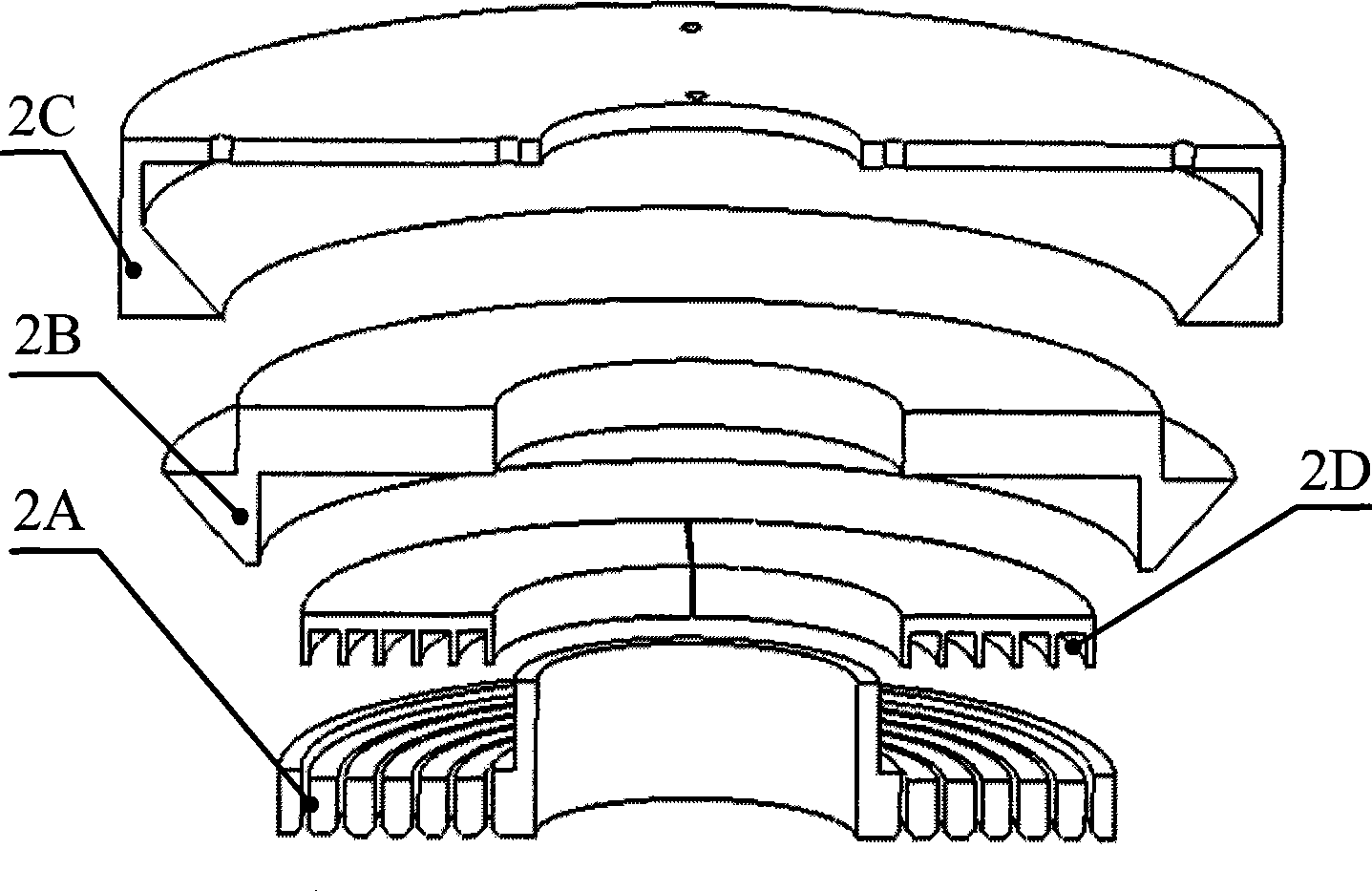

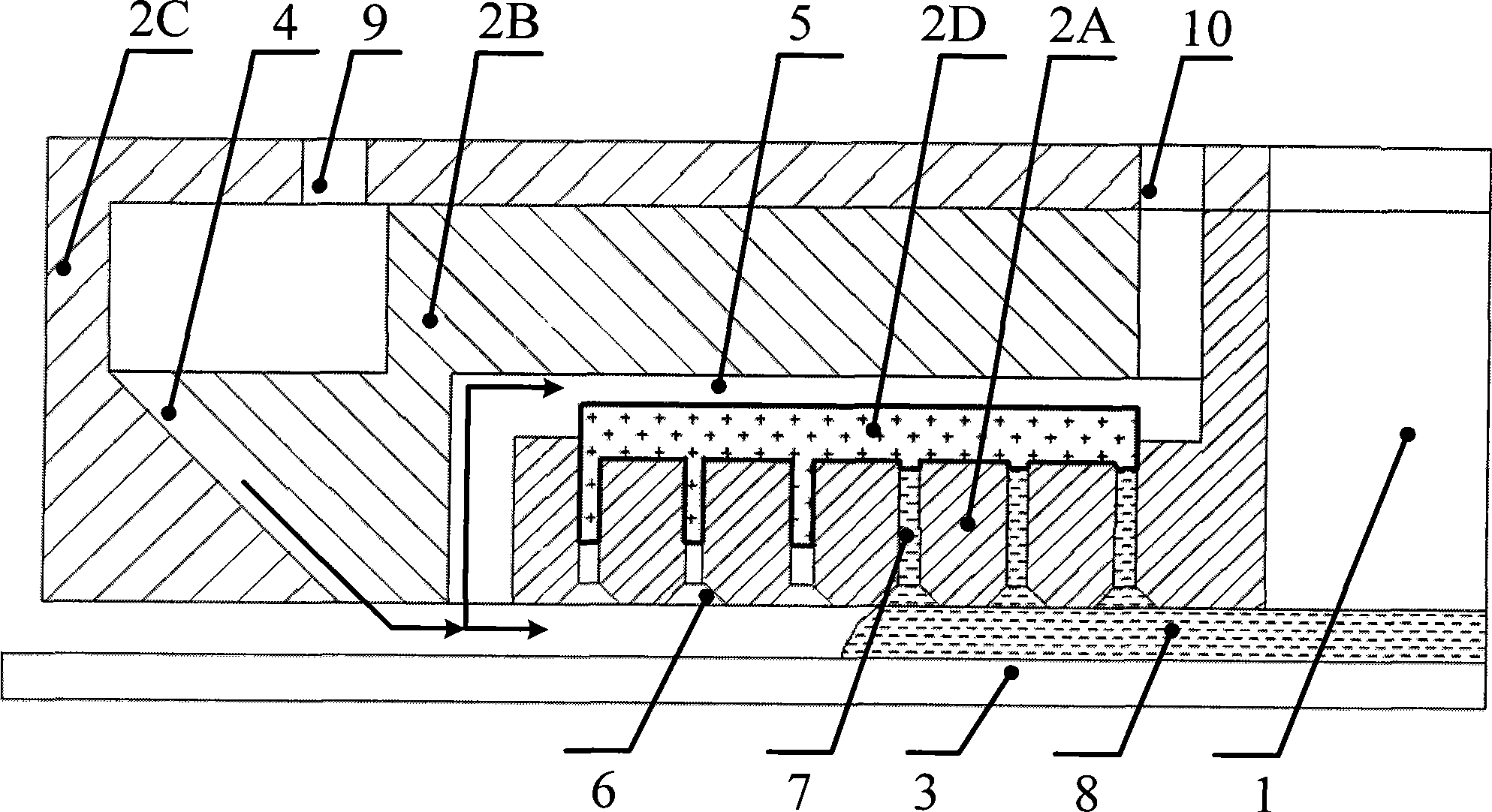

[0027] like figure 1 , figure 2 , image 3 As shown, the present invention provides an immersion adaptive gas sealing device 2 between the projection lens group 1 and the substrate 3; it is characterized in that the immersion adaptive gas sealing device 2 is composed of an inner member 2A, a middle member 2B, an outer Component 2C and deformable part group 2D; where:

[0028] 1) Internal member 2A: There are 6 to 8 tension ring grooves 6 at the bottom of the inner member on the lower surface of the inner member 2A, and an annular through hole 7 is opened at the top of each tension ring groove 6 at the bottom of the inner member;

[0029] 2) Deformable part group 2D: The deformable part group 2D is composed of four identical independent deformable parts distributed in a ring shape, and the lower part of each deformable part has the same number of con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com