Processes and apparatuses for the production of crystalline organic microparticle compositions by micro-milling and crystallization on micro-seed and their use

A grinder, the technology of crystallizing particles, applied in the field of endeavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

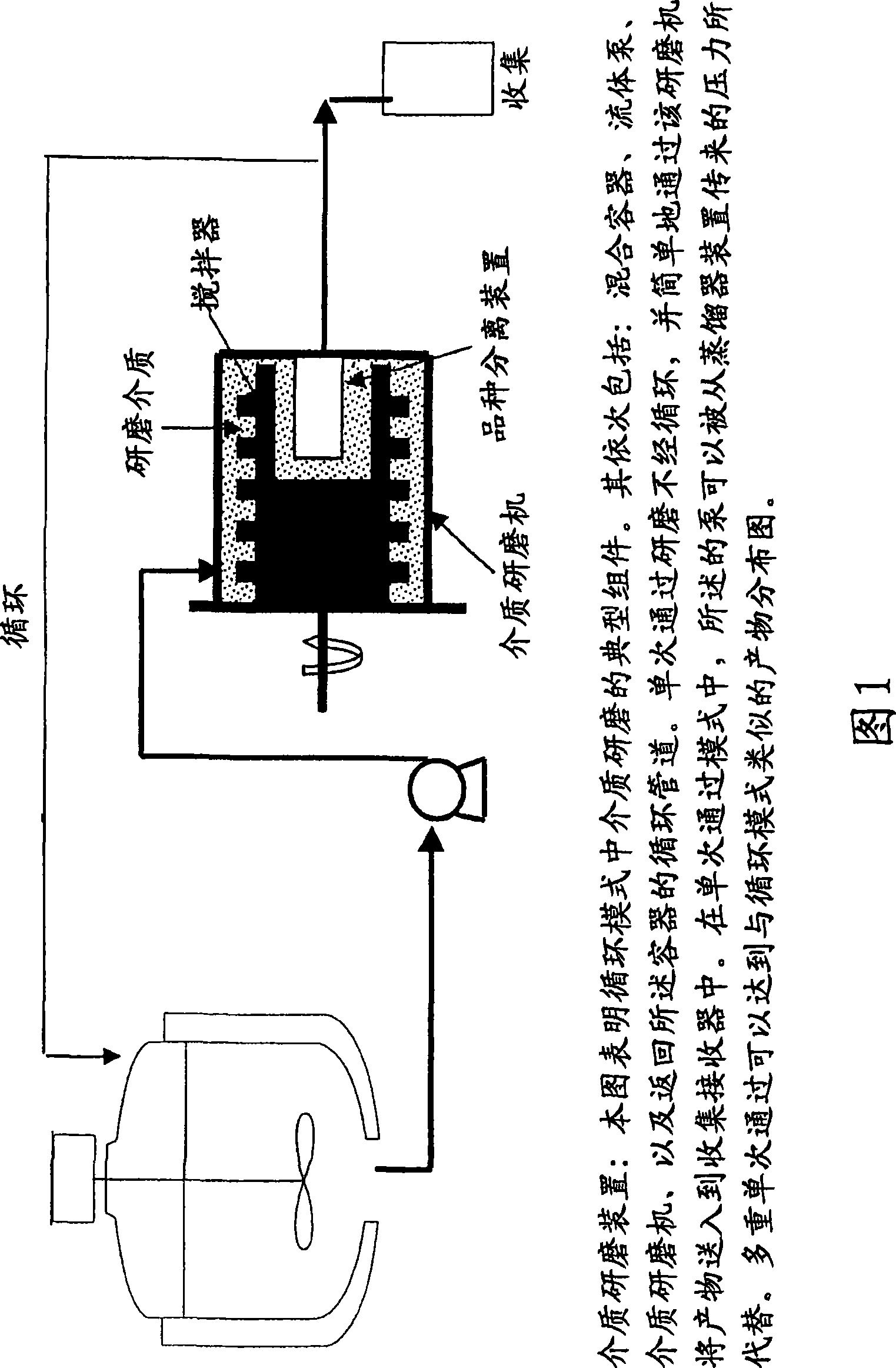

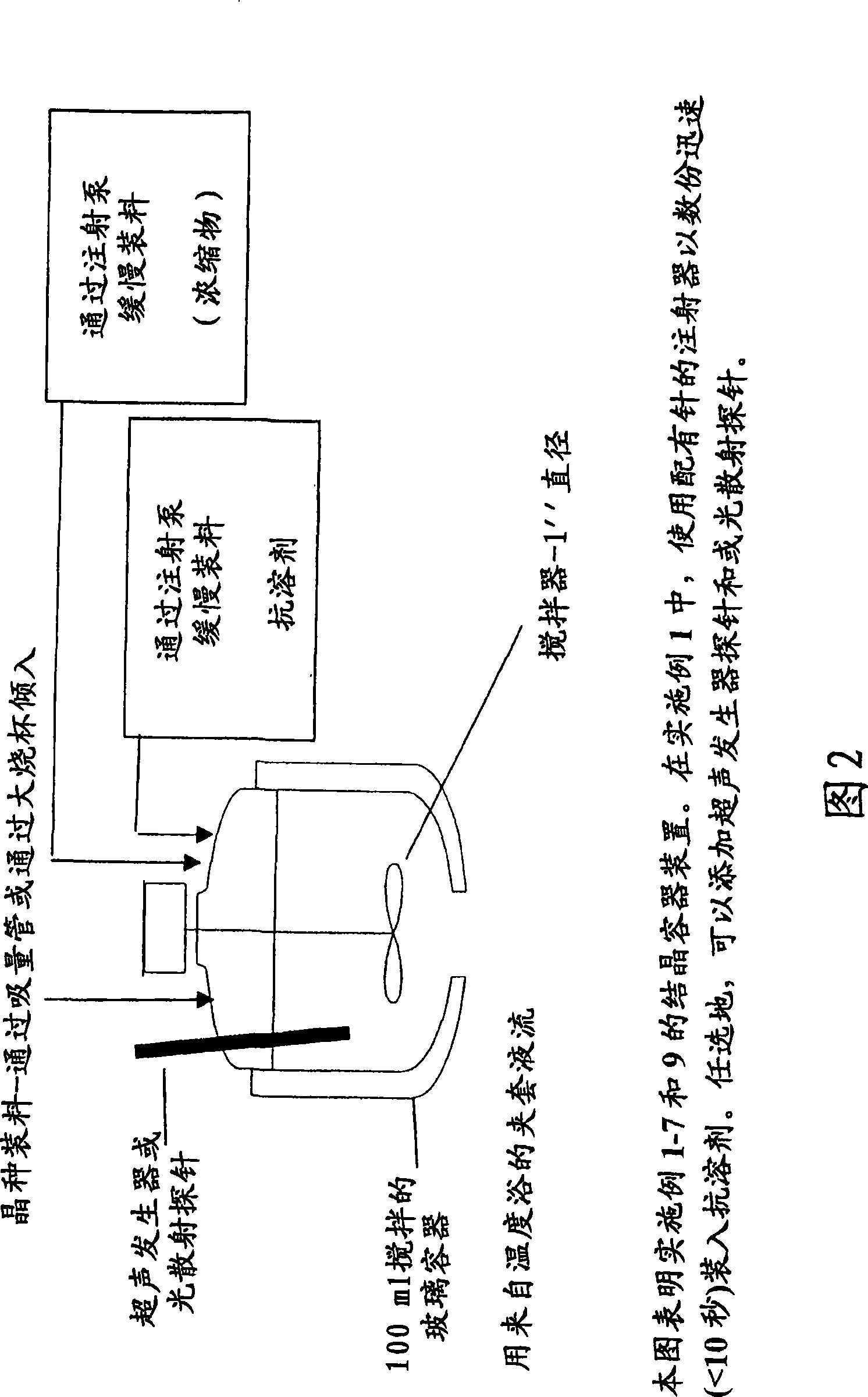

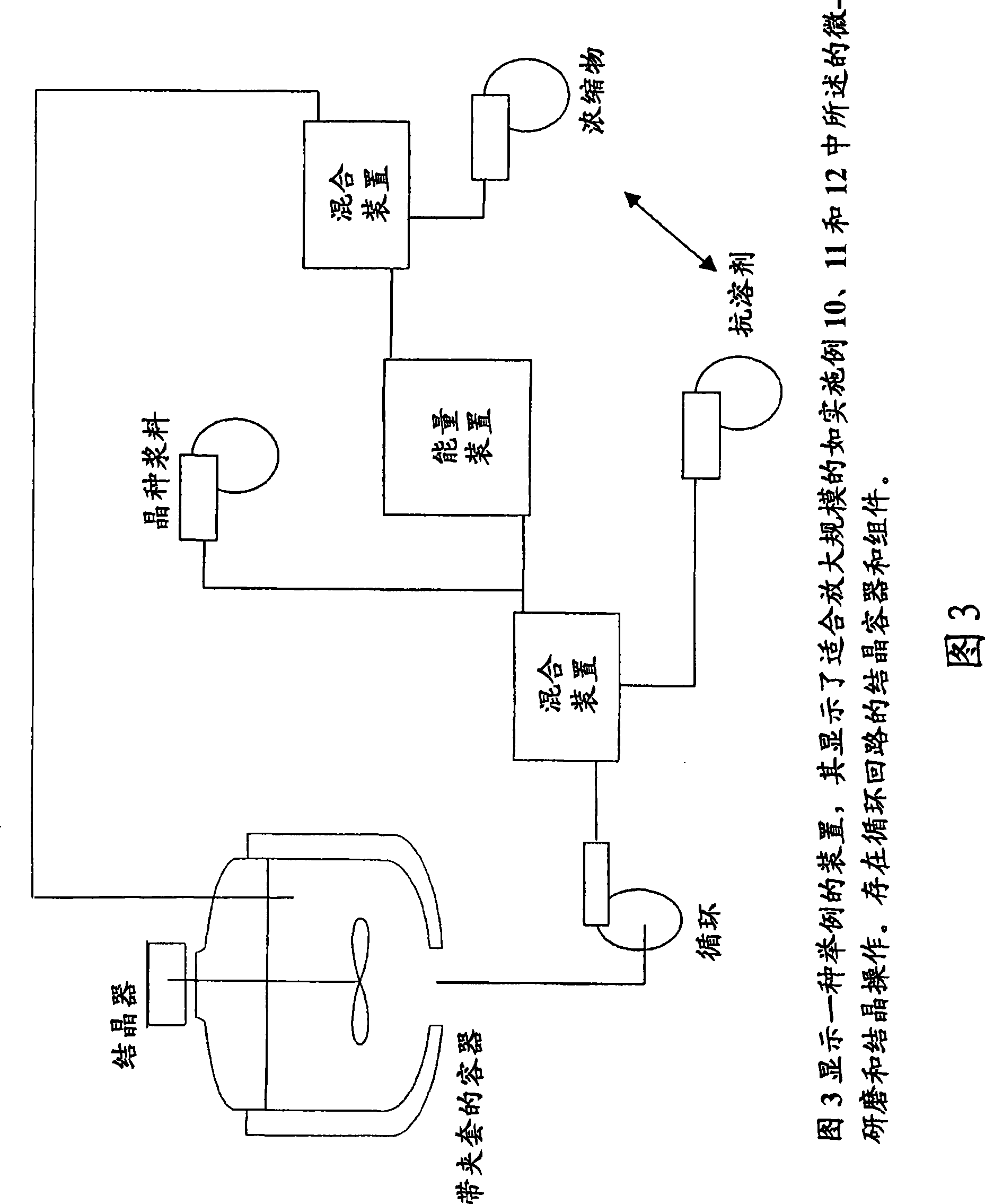

Method used

Image

Examples

example

[0098] The microcrystalline seed particles are prepared by one of two mills: a 600ml disc mill indicated by the KDL model, produced by -Mill made. The mill compartment is chrome treated and the agitation disc is yttrium stabilized zirconia. The mill was loaded with approximately 1900 grams of yttrium stabilized zirconia beads of uniform diameter. The 160ml agitated Mini-Cer grinder includes a ceramic compartment and a ceramic stirrer and is manufactured by Netzsch Inc. The mill was loaded with approximately 500 grams of yttrium-stabilized zirconia beads of varying sizes and uniform diameter. Beads for these grinders are made from Inc., Wyncote, Pennsylvania. They are highly polished and originally manufactured by TOSOHUSA, Inc.

[0099] Particle surface area was determined using BET multipoint analysis on GEMINI 2360 (by Instrument Corporation Inc., Norcross, Georgia) unless otherwise stated.

Embodiment

Embodiment 8

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com