Method and apparatus for preparing epoxypropane by catalyzing propone epoxidation at supercritical condition

A propylene oxide and supercritical technology, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of inability to remove products and by-products in time, easy deactivation of catalysts, poor diffusion performance, etc. problem, achieve the effect of overcoming the control of diffusion kinetics, reducing separation difficulties, and promoting product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

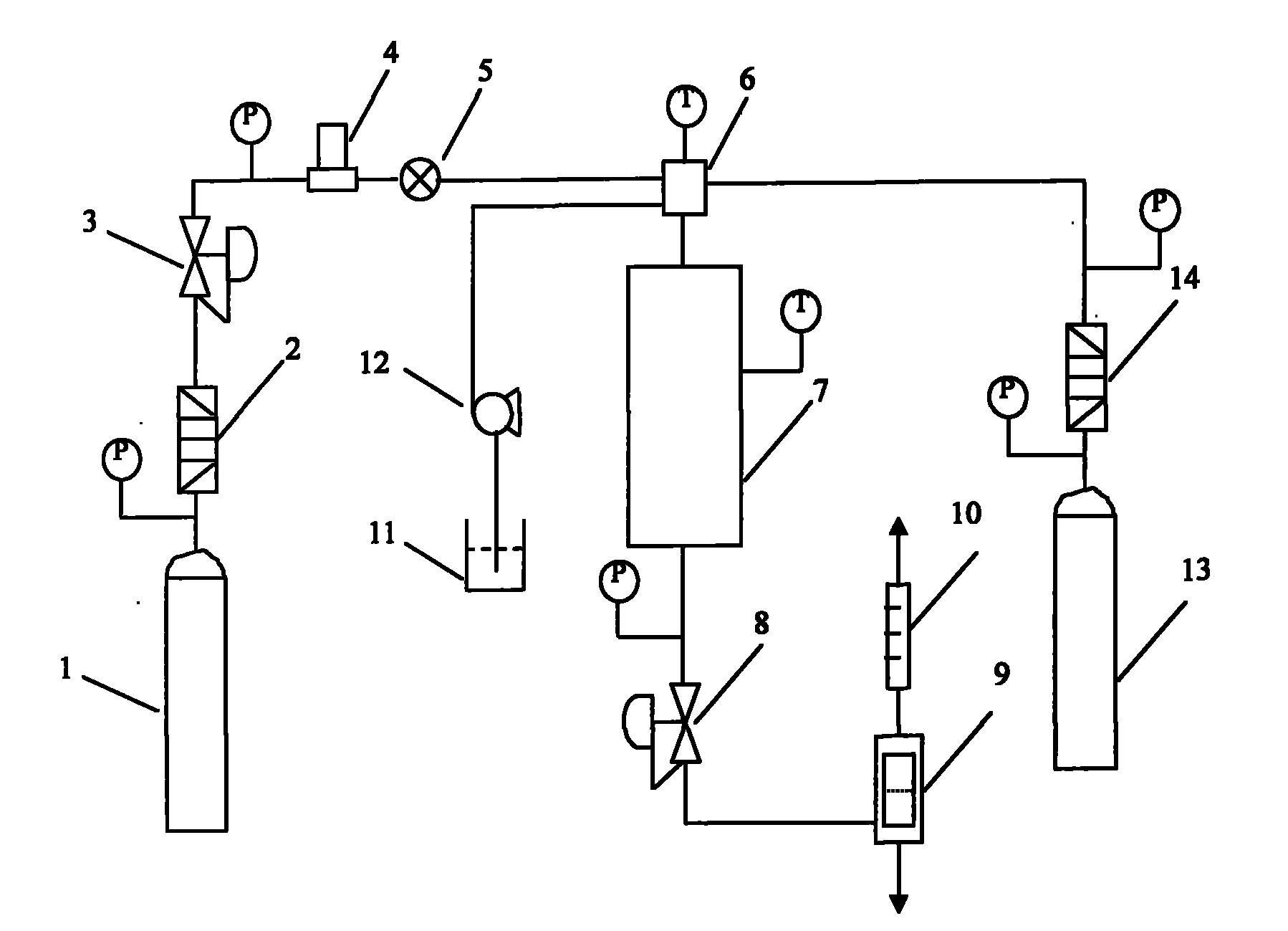

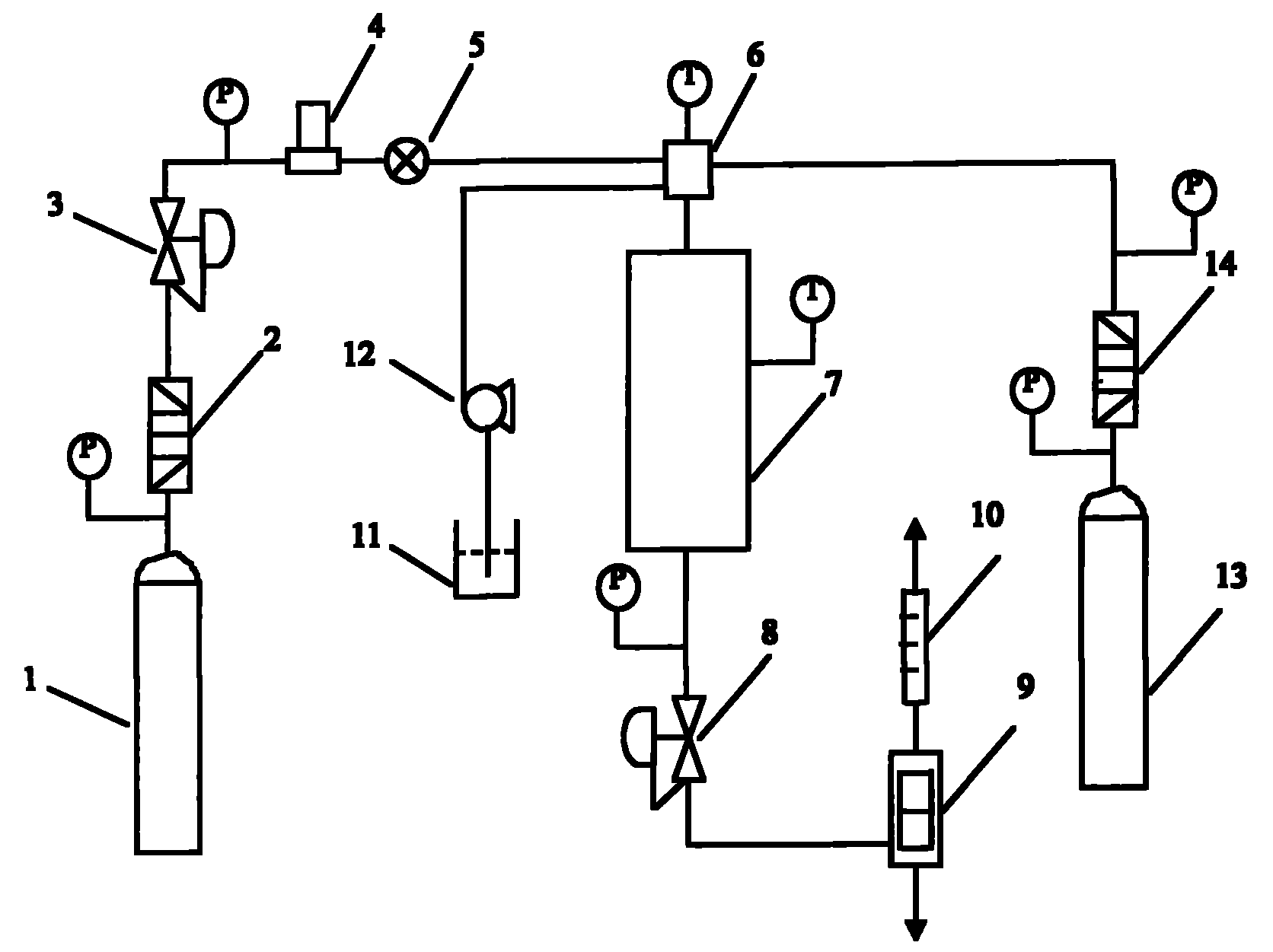

Method used

Image

Examples

Embodiment 1

[0016] TS-1 catalyzes the epoxidation of propylene under traditional conditions. The catalyst uses TPAOH as a template to synthesize small-grain TS-1 (0.2 μm in particle size), the dosage is 0.3 wt%, the propylene pressure is 0.4 MPa, and the hydrogen peroxide is used. The concentration was 1 mol%, the concentration of co-solvent methanol was 4wt%, the reaction temperature was 40°C, no carbon dioxide was used, the conversion of hydrogen peroxide was 85%, the selectivity of propylene oxide was 89%, and the yield of propylene oxide was 75.6%.

Embodiment 2

[0018] TS-1 catalyzes the epoxidation of propylene under traditional conditions. The catalyst uses TPABr as the template to synthesize large-grained TS-1 (particle size is 1 μm), the dosage is 0.3 wt%, the propylene pressure is 0.4 MPa, and the hydrogen peroxide concentration is 0.3 wt%. is 1 mol%, the concentration of co-solvent methanol is 4 wt%, the reaction temperature is 40°C, and carbon dioxide is not used. The hydrogen peroxide conversion was 79%, the propylene oxide selectivity was 48%, and the propylene oxide yield was 38%.

Embodiment 3

[0019] Example 3: TS-1 catalyzed propylene epoxidation under supercritical conditions, the catalyst used TPABr as a template to synthesize large-grained TS-1 (with a particle size of 1 μm), the dosage was 0.3 wt%, and the propylene pressure was 0.65 MPa , the concentration of hydrogen peroxide is 1mol%, the concentration of co-solvent methanol is 4wt%, the pressure of carbon dioxide is 7.6MPa, and the reaction temperature is 40℃. The reaction results: the conversion rate of hydrogen peroxide is 98%, the selectivity of propylene oxide is 92%, and the yield of propylene oxide is 90.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com