Non-digging tube-pulling construction method

A technology of trenchless and construction method, applied in the field of trenchless pipe-drawing construction method, can solve the problems of inability to meet construction conditions, complicated underground pipelines, and inability to construct, achieve considerable economic benefits, reduce labor intensity, and construction speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

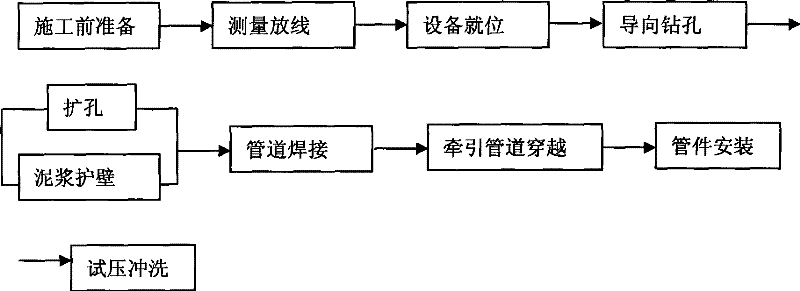

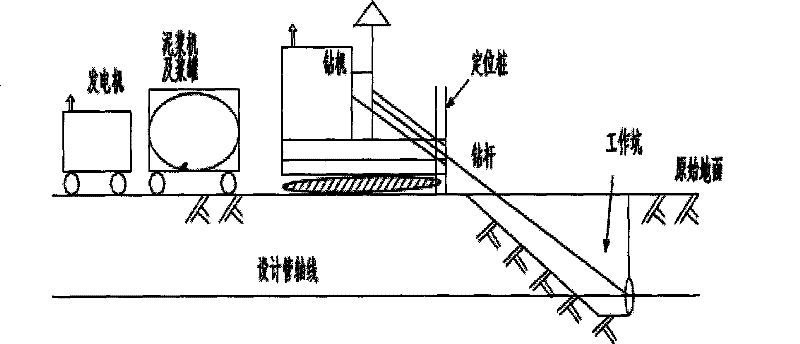

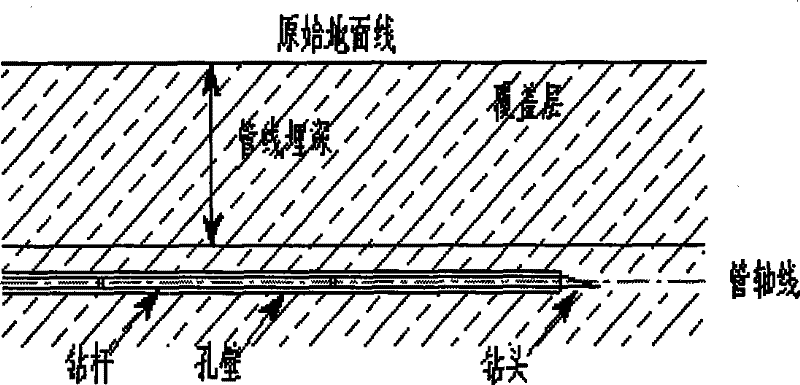

Method used

Image

Examples

example 1

[0055] Example 1. In a factory, the reclaimed water stake number is 2+760~3+096, the pipeline length is 336m, the original design DN500 ductile iron pipe is grooved, the water surface elevation is 9.996~11.086, and the average buried depth of the pipeline is 2m. The building cannot be demolished, so the pipe-drawing construction is used here. The 336m-long pipe is divided into two sections, 200m for one section and 136m for one section. The pipe material is changed to φ500PE pipe. During the pipe-drawing construction process, there was no normal operation of the factory, and the structural quality of the house was not damaged in any way. The construction saved 3,500 square meters of earthwork excavation and backfilling, saved labor costs of 120,000 yuan, and saved construction costs of 420,000 yuan. The construction period was 15 days ahead of schedule, and the project was completed and accepted.

example 2

[0056] Example 2. The reclaimed water (reclaimed water) reuse project of a plant passes through the swimming pool. The reclaimed water stake number is 3+504~3+700, the length of the pipeline is 196m, the upper level of the water surface is 9.193~9.000, and the average buried depth of the pipeline is 3.2m. Pipe drawing construction, 196m of pipe drawing at a time, the pipe material is φ500PE pipe. Reduce the amount of earthwork excavation and backfill by 2,000 cubic meters, save 80,000 yuan in labor costs, save 250,000 yuan in construction costs, advance the construction period by 10 days, and pass the project completion acceptance.

example 3

[0057] Example 3. The pipe jacking project of a sewage pipe network, stake number: 0+035~1+500, plus 300m. The supervisor is located under the slow lane of the road, and is constructed by drawing pipes, and the pipes are φ500PE pipes. Save 1,900 square meters of earthwork excavation and backfill, save 80,000 yuan in labor costs, save 250,000 yuan in construction costs, advance the construction period by 10 days, and pass the project completion acceptance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com