Method for real-time detecting bearing shell vibration by image analysis

An image analysis and shaft detection technology, applied in the field of image analysis, can solve the problems of complex installation, expansion, and high requirements for professional operation, and achieve the effects of improving efficiency, reducing costs, and reducing installation complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiment will be described in detail below in conjunction with the accompanying drawings.

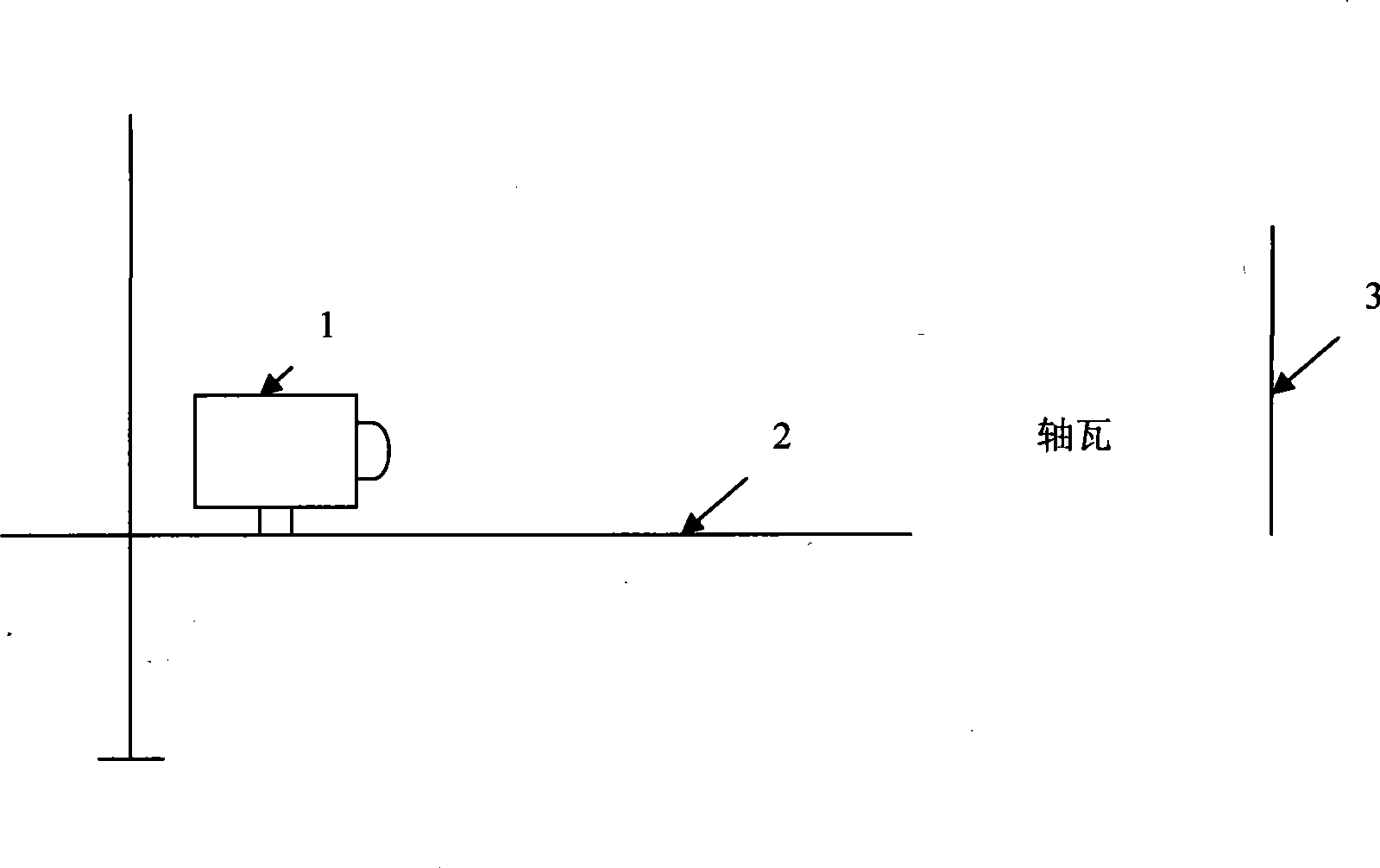

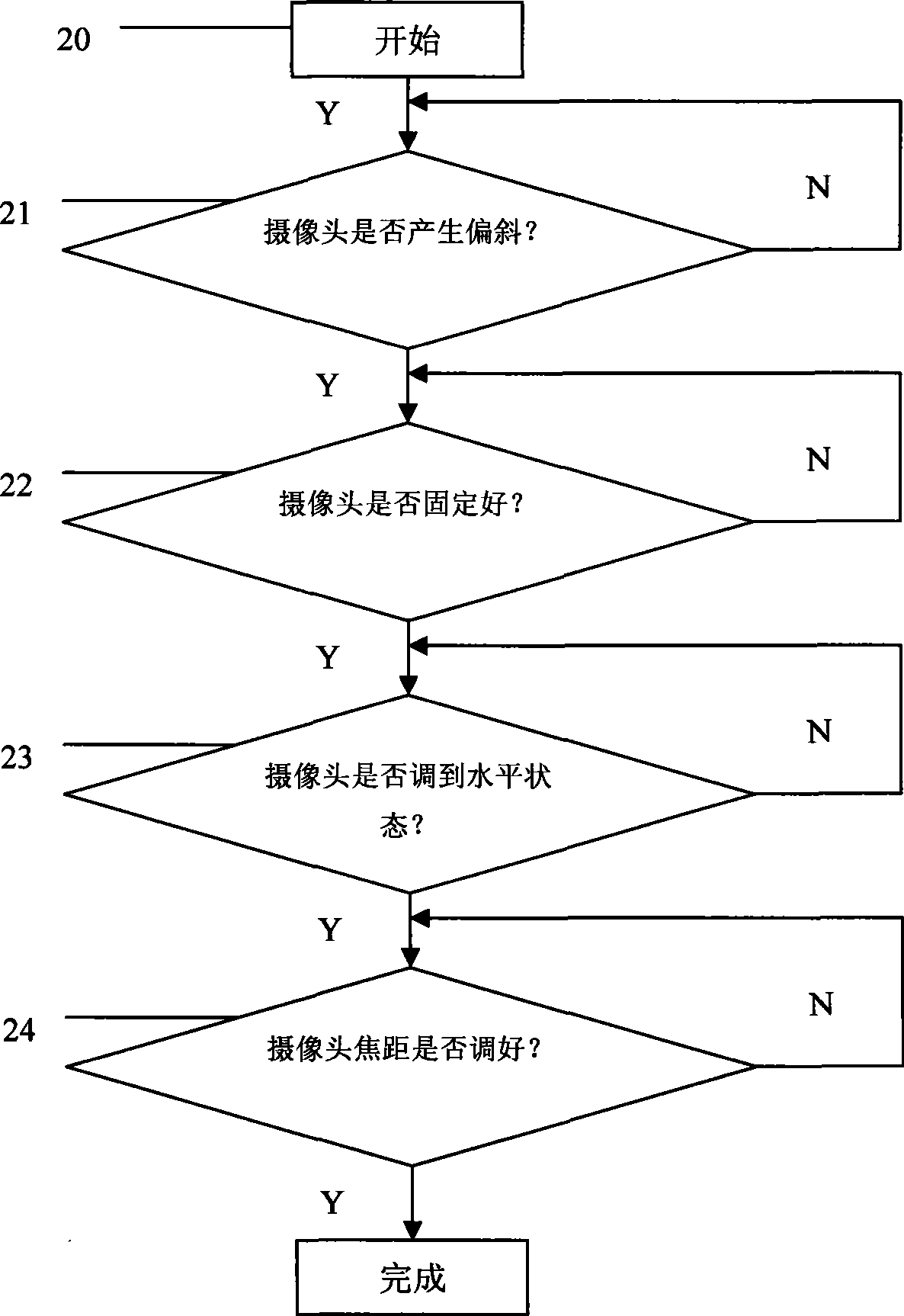

[0019] Such as figure 1 As shown, 1 is the image acquisition device, 2 is the fixed bracket, and 3 is the monochrome baffle; the image acquisition device is fixed on the bracket, and the appropriate height and distance are adjusted so that the lens is vertically aligned with the center of the axis. The cross-section of the shaft is vertical, and a monochromatic baffle is placed behind the shaft to make the shaft easy to distinguish from the external environment. The image acquisition device is connected to the computer interface through a cable, and the user installs the driver of the image acquisition device on the computer after correctly connecting the hardware. After the system is running, the image acquisition equipment transmits the signal to the computer through the communication line, and converts it into a digital image signal that the computer can recog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com