Optimized making method based on flat-plate wave guide mobile afebrile array wave guide grating

A technology of arrayed waveguide grating and slab waveguide, which is applied in the coupling of optical waveguide, etc., to achieve the effect of reducing production difficulty and production cost, reducing the requirement of substrate flatness, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The optimized manufacturing method of the mobile athermal arrayed waveguide grating based on the slab waveguide of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0077] The optimized manufacturing method of the mobile athermal arrayed waveguide grating based on the slab waveguide of the present invention includes the following steps:

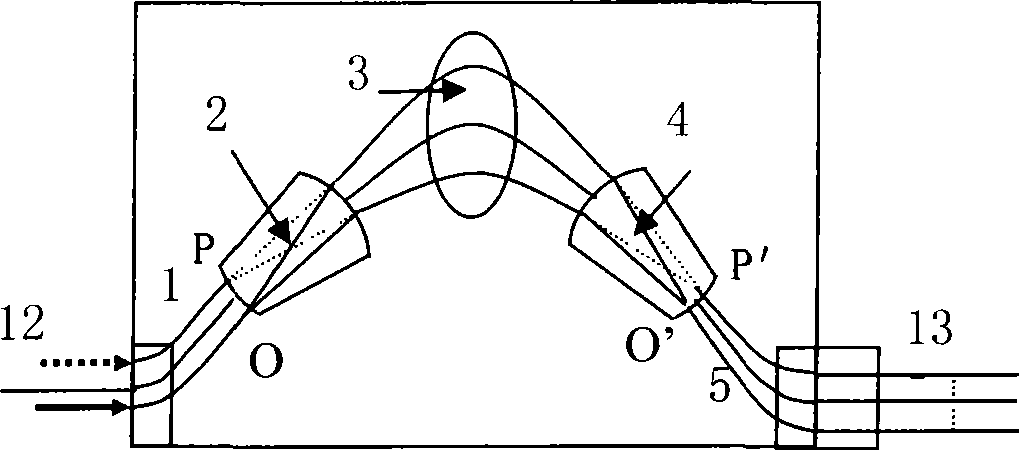

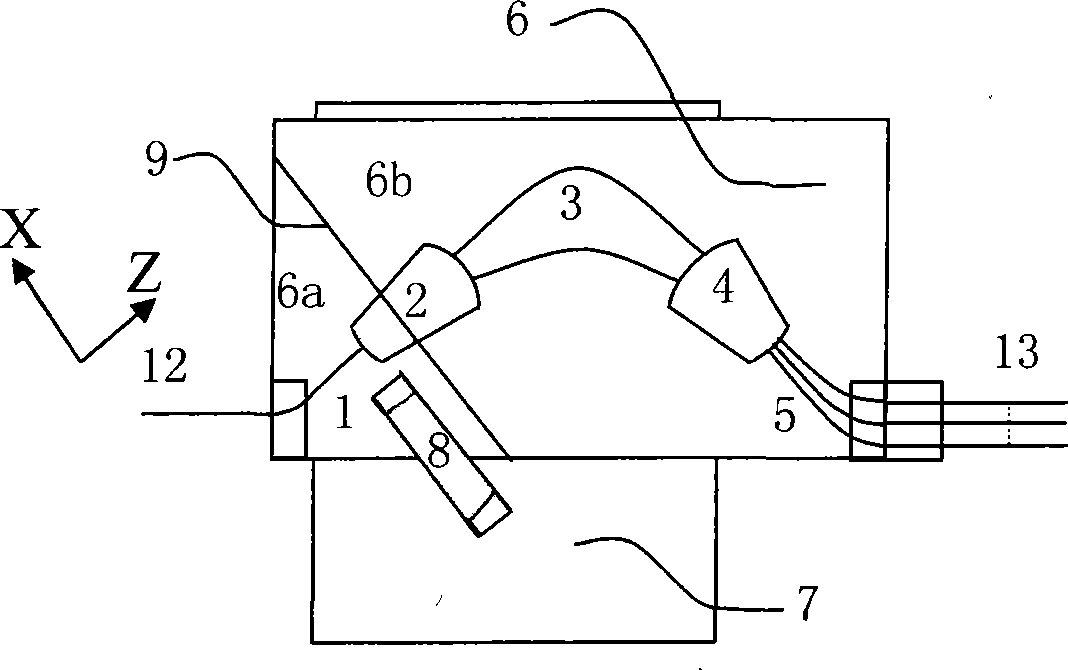

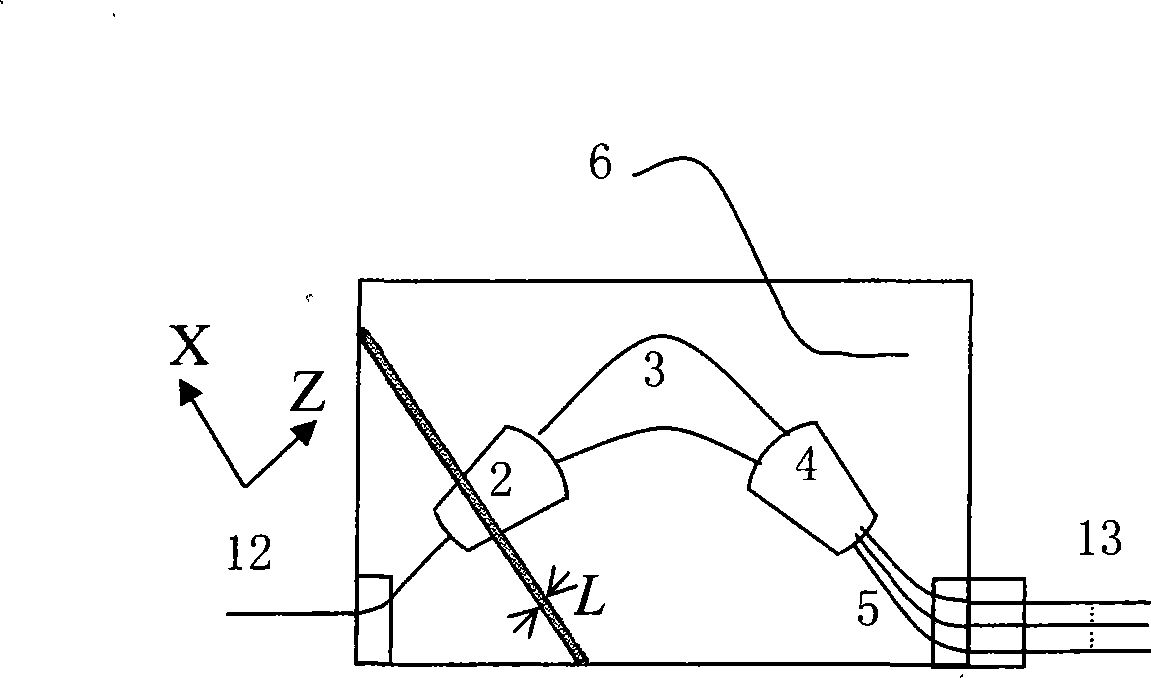

[0078] (1) if image 3 As shown, AAWG (AAWG: Athermal Arrayed waveguide grating athermal array waveguide grating); the AWG chip 6 is coupled, debugged and cured with the input fiber array 12 and the output fiber array 13, which is called the first coupling debugging and curing of AAWG, and the performance of all output channels of the output fiber array 13 is tested Parameter a1; for simplicity, according to the characteristics of the performance parameters of the AWG chip 6 itself, it is also possible to test only the performance parameter a1 of the 1, N / 2 and N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com