Photovoltaic devices having conductive paths formed through the active photo absorber

A solar photovoltaic and photovoltaic module technology, applied in the field of large-area photovoltaic solar modules, can solve problems such as large resistance and loss of active area of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in terms of CIGS PV (photovoltaic, PV) solar modules. However, it will be apparent to those skilled in the art that light-absorbing photovoltaic films other than CIGS can be used in the practice of the present invention. Furthermore, the term "TCO" as used herein shall include any suitable transparent conductive film including those comprising a buffer layer such as taught in the Shafarman & Stolt reference cited therein.

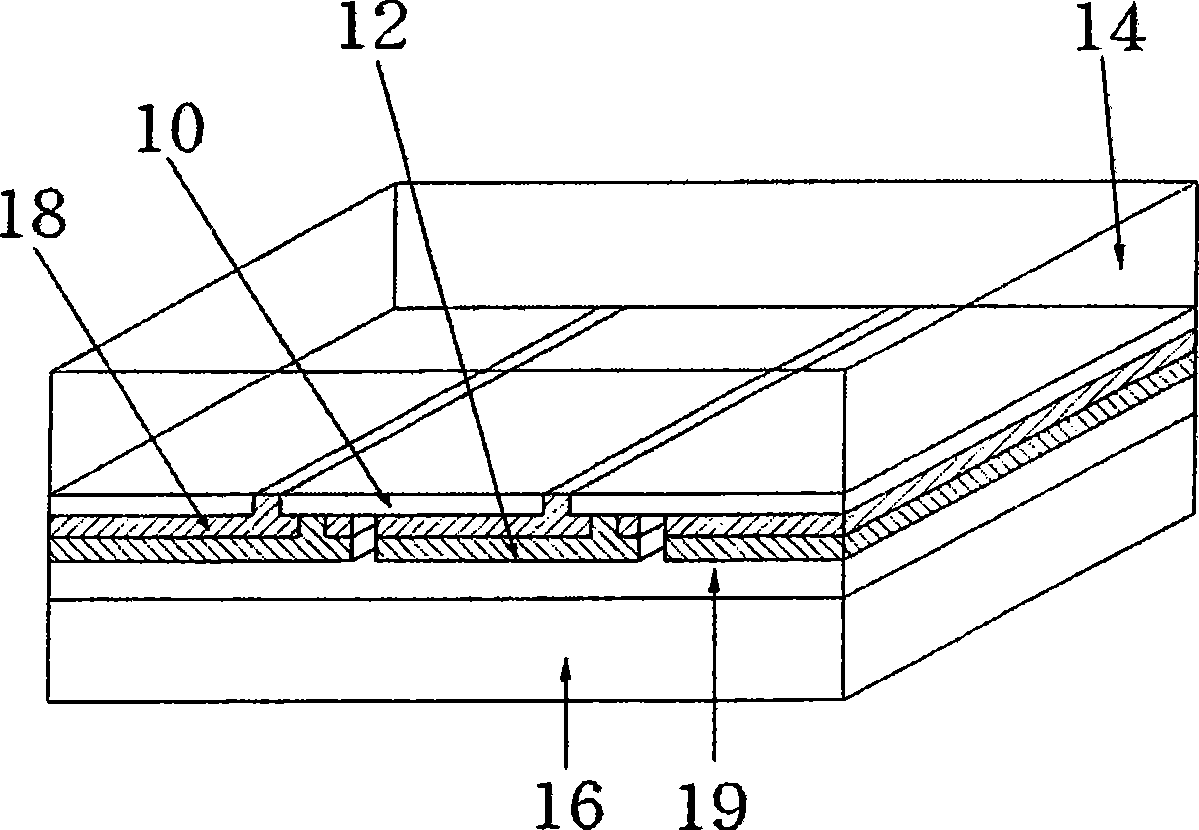

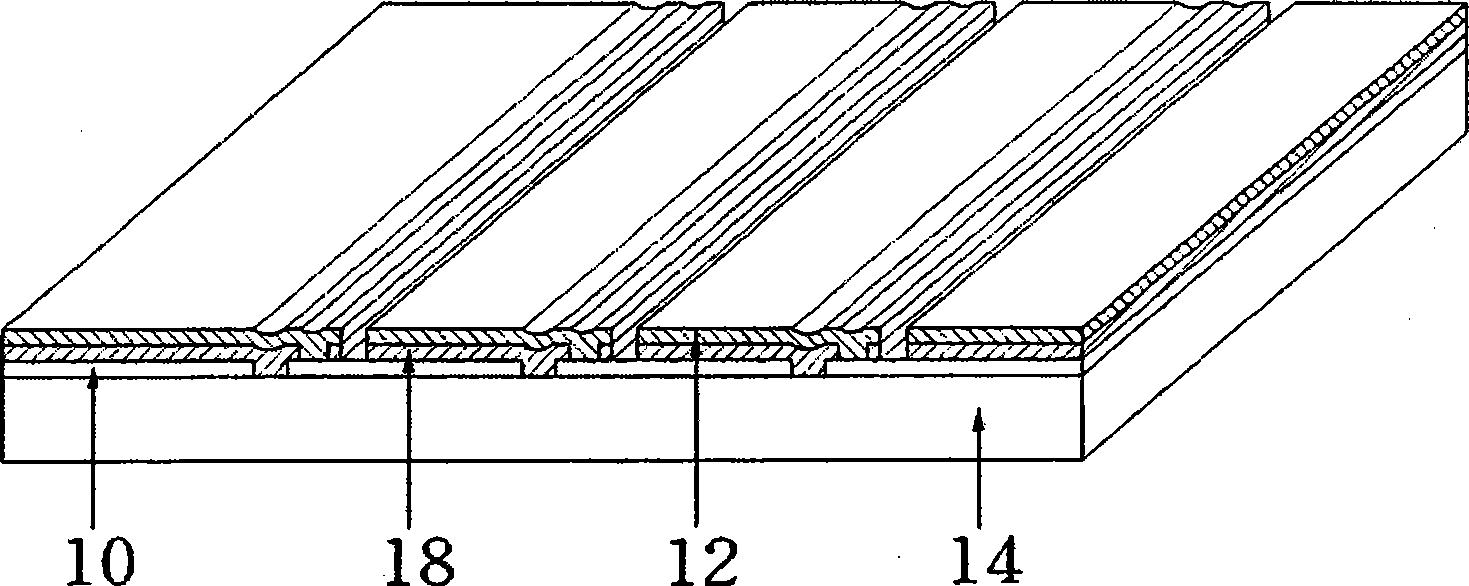

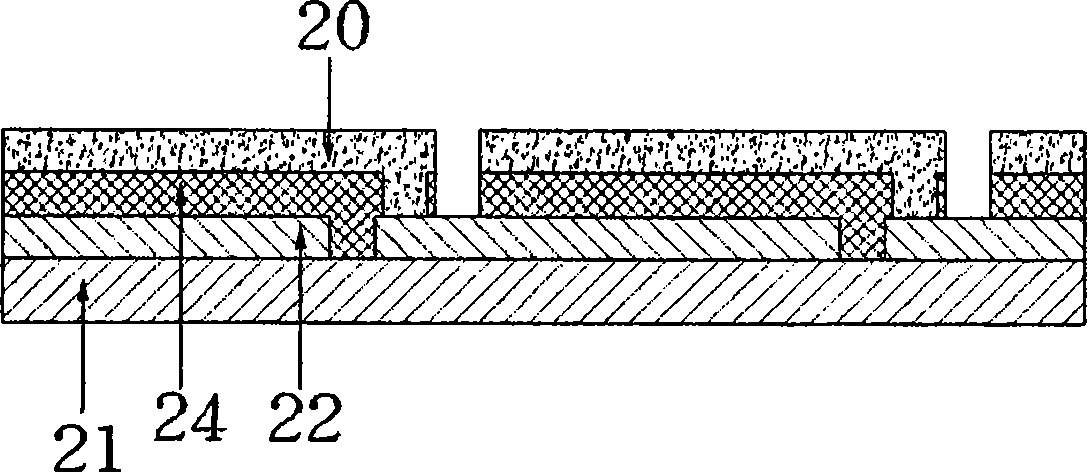

[0056] In general, according to the invention, a solar electric module comprises an array of interconnected thin-film PV solar cells in series formed on a substrate. Each cell of the array includes a back electrode spaced from the back electrode of an adjacent cell, a light-absorbing PV film in contact with the back electrode of a cell and extending at least partially to the back electrode of the adjacent cell, a TCO on the PV film A front electrode, the small portion of the PV film is located on a small porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com